The model could serve as a valuable instrument for designers seeking to revolutionize sneaker design.

The pace of technological advancements in shoe manufacturing surpasses the rate at which new shoe designs can be assessed through human subject testing. A recent study introduces a model that may be used to predict the impact of new shoe features on the performance of runners, therefore facilitating the design process.

Engineers at MIT have created a novel model that predicts the impact of different shoe qualities on a runner’s performance.

An instrument for enhancing running footwear: This uncomplicated model takes into account your stature, mass, and shoe attributes such as rigidity. It assumes your identity and demonstrates how you would perform while wearing a particular shoe.

Researchers employ the model to observe the alterations in your running pattern that occur when using various types of footwear. They discover the shoe that allows for the most efficient energy utilization during running, deeming it the epitome of performance.

The model exhibits exceptional proficiency in contrasting highly dissimilar shoes, but its performance is less impressive when it comes to comparing similar ones, such as those found at retail establishments. Researchers believe that it is most advantageous for shoe designers who aspire to make novel and distinctive shoes.

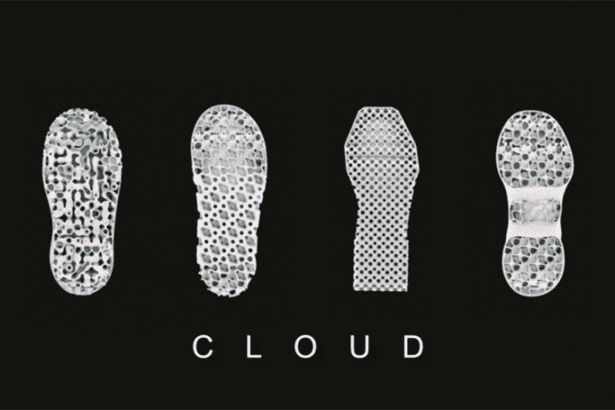

Sarah Fay, a postdoctoral researcher at MIT’s Sports Lab and the Institute for Data, Systems, and Society (IDSS), explained that shoe designers are now utilizing 3D printing technology to create shoes with a significantly broader range of characteristics compared to traditional foam-based manufacturing methods. Our methodology has the potential to assist them in creating innovative shoes that are also very efficient.

The crew anticipates enhancing the concept to enable clients to eventually utilize a comparable iteration for selecting shoes that suit their running style.

The team engaged in a collaborative effort with the sneaker business, particularly with companies utilizing 3D printing technology for large-scale shoe manufacturing. The focus was primarily on 3D-printed midsoles, which featured intricate patterns and gave specific areas either increased resilience or rigidity.

The difficulty lies in forecasting the response of a runner to a completely unfamiliar shoe. It requires comprehending the mechanics of the runner and the distinctive characteristics of the shoe.

Fay and Hosoi initiated the process by streamlining a runner’s motions using a rudimentary framework. Their inspiration sprang from Thomas McMahon, a renowned biomechanics specialist at Harvard University during the 1970s. McMahon employed a basic model known as the’spring and damper’ to get insights into the fundamental mechanics of running. According to McMahon’s concept, runners are expected to have improved performance on tracks that are softer and more elastic, which align with their natural stride.

This observation, although now considered ordinary, was revolutionary during that period. According to McMahon’s research, Harvard went as far as modifying their indoor track, resulting in faster running times due to the softer and more elastic surface.

McMahon’s research highlighted the fact that even using a simplified model that does not encompass all aspects of the human body, we may still gain significant knowledge about designing for athletic performance.

McMahon’s research had an impact on the streamlined model that Fay and Hosoi created. Their model depicts a runner as a central point of mass with a hip that rotates and a leg that can stretch. The leg is attached to a shoe-shaped container that has the ability to modify its springiness and absorb shocks both vertically and horizontally.

The concept involved entering an individual’s fundamental characteristics (such as height, weight, and leg length) as well as the shoe’s material attributes (specifically, the rigidity of the front and back midsole) into the model. By doing so, they could replicate the manner in which an individual would run while wearing that particular footwear.

Acknowledging that a runner’s gait encompasses:

An intangible attribute.

Referred to as the ‘biological cost function.’

The team sought to ascertain this function.

It is a variable that a runner may unintentionally reduce in importance when running. The researchers aimed to identify a shared biological metric that applies to the majority of runners. They hypothesized that by doing so, they might forecast an individual’s running style when wearing a certain shoe and ascertain which shoe yields optimal running performance.

In order to provide this information, the team consulted a prior study conducted on a treadmill, which assessed multiple factors related to runners, such as impact force, joint angles, motion, step elasticity, and muscle exertion. Importantly, the participants in the study were all wearing the same type of running shoe.

Fay explained that instructing our algorithm to “optimize your gait on these two factors” enables us to generate gaits that closely resemble the data we possess. This provides us with assurance that the model has the ability to accurately forecast individuals’ running patterns, even when their footwear is altered.

During the last phase, the researchers conducted simulations using several shoe designs. They utilized the model to forecast a runner’s walking pattern and evaluate the effectiveness of each pattern when wearing different types of shoes.

Citation:

The individuals mentioned are Anette (Peko) Hosoi and Sarah Fay. Applying optimal control techniques to shoe design to simulate and analyze running. The article is published in the Journal of Biomechanical Engineering and can be found using the Digital Object Identifier (DOI) 10.1115/1.4064405.