How did you launch FoamPod?

I’ve always been interested in the history of sneakers and all the different collaborations. In New York, where I spent a lot of time, everyone was buying into that culture. My first client was a footwear manufacturing company: we designed a virtual shoe for them. When I was visiting the factory in China, I saw how many different steps it takes to create a shoe: 50 materials per shoe. It’s not sustainable: in 2021 alone, around 20 billion pairs ended up in landfill. That inspired me to start looking into 3D-printing technology. Now that the quality of 3D-printing has improved, it’s cheaper and there’s less of a knowledge barrier, it seems to be the perfect time to get into the game.

Why 3D printing?

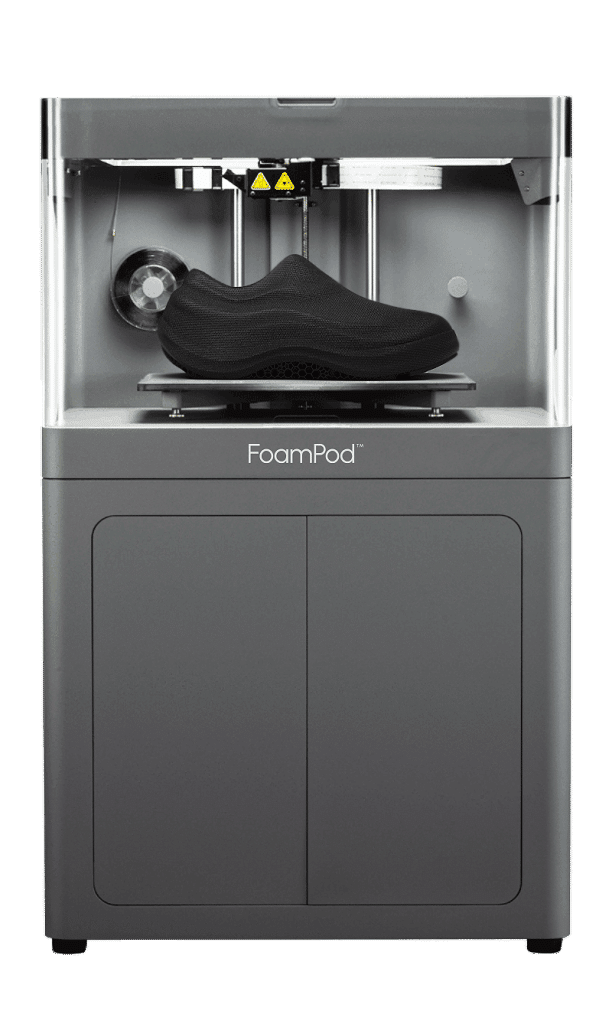

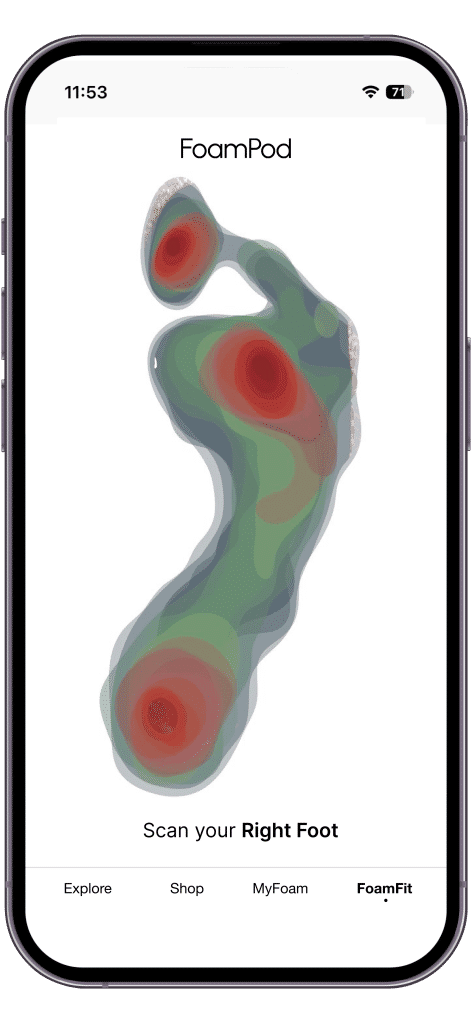

If you look at manufacturers like Nike and Adidas, they can only create new iterations of their shoes twice a year because they need to create a cast and do injection moulding. With 3D-printing, however, we can do these iterations rather quickly, including anything personalised. We’re also launching an app as a part of our e-commerce platform that’ll use AR to scan our customers’ feet to determine their exact dimensions. Thanks to 3D printing, we can also customise the sole, making it wider or adjusting the softness by amending the lattice structure [repeated patterns that, when connected, form three-dimensional shapes]. Because our machines are customised, too, we can print one pair in under 12 hours – normally, it would take around 40 hours.

What materials do you use at FoamPod?

Thermoplastic Polyurethane – TP – a carbon-neutral and biodegradable polymer. Of course, the means of TPU production can hardly be called carbon-neutral, but the fact it’s durable and can be broken down to be reused means it offsets the emissions caused by its production. TPU is a lightweight and versatile synthetic material that can be made UV- and water-resistant. We’ve been developing custom filaments – thermoplastic feedstock for 3D printers – with the materials company Polymaker. The issue came when we wanted to adjust the softness of the final product: we had to customise all the printers to do that. We have around 30 machines in our Kowloon facility.

Are FoamPod shoes recyclable?

TPU can be broken down and used to create another shoe or something else. We’re launching a circular programme later this year, called ReFoam. Our customers will be able to send us their FoamPod pair back six months after purchase, and we’ll chop it into filaments and reprint a fresh pair, which this customer will receive at a fraction of the price.

Do you keep any inventory?

Not really. Not at the scale of these big brands. Inventory is a huge problem for a lot of footwear giants. And, for smaller brands, keeping inventory to support the first year of operations might cost from 500,000 to a million dollars, which is a serious investment.

Do you envision physical stores?

Yes.

With no inventory?

We’ll have a minimum quantity of stock and a few machines in the store that will print on-site. Physical locations allow people to experience the product before buying it. There’s also a stigma surrounding 3D- printed shoes – people might think they’re too rigid to wear. But when you hold a FoamPod pair, you can feel how bouncy and flexible it is.

Who do you hope FoamPod will cater to?

Our early adopters are somewhat tech enthusiasts. And our target audience is Asian Gen Zs. We’re launching in Hong Kong this month with plans to expand to Seoul and Tokyo. We’re also launching interchangeable outsoles. I hike a lot, so every six months I’d need to change my hiking shoes because the outsoles wear down and lose traction. So for me, coming up with these interchangeable outsoles is logical, though it’s nothing new or ground breaking. We’ll first offer three outsoles that fit one activity, so, these will be for travel and all-day comfort. And then we see ourselves expanding into hiking and trail running. At some point, we’re also hoping to offer fully customised outsoles.

How durable are these shoes?

They can last for as long as two to three years.

Are you going to tie your Web3 expertise into FoamPod?

I’ve been working on digital twins, so we’ll be tying that in. We have a digital passport app called Dot Pass – on a very simple level it connects your physical product with a digital twin. There’s going to be a law introduced in the EU that will oblige luxury brands to connect their products to digital twins for sustainability and traceability. This technology also increases engagement. Recently, for example, Balenciaga launched a bag that came with a unique track, Coach had products with NFC (near field communication) tags that allowed for tokens to be redeemed when scanned. We’re taking this a step further. Since we already have the infrastructure in place, we’re going to be using digital twins to create more meaningful collaborations with the artists we love, offering our customers access and a variety of experiences.