Plantar fasciitis—a condition marked by persistent heel pain—affects millions worldwide, significantly limiting mobility and quality of life. For decades, traditional orthotic treatments have helped alleviate pain by supporting the foot’s biomechanics. However, modern 3D printing technology is revolutionizing foot care with custom, on-demand solutions. In this article, we compare traditional orthotics with 3D printed alternatives to help you decide which approach may provide the best relief for plantar fasciitis.

Understanding Plantar Fasciitis and Its Impact

Plantar fasciitis is caused by irritation or degeneration of the plantar fascia, a thick band of tissue connecting your heel bone to your toes. This condition is often characterized by sharp heel pain—especially with the first steps in the morning or after prolonged rest—which can severely disrupt daily activities.

Key Symptoms and Challenges:

- • Persistent Heel Pain: Often concentrated at the bottom of the heel.

- • Stiffness and Inflammation: Limiting foot movement and making walking difficult.

- • Reduced Quality of Life: Daily activities and exercise routines may be compromised.

Traditional Treatment Options:

- • Rest and Physical Therapy: To reduce inflammation and strengthen muscles.

- • Prefabricated Insoles: Off-the-shelf solutions offering general support.

- • Custom Molded Orthotics: Devices manually crafted from plaster casts of your foot.

While these methods have helped many, they sometimes fall short of providing the precise, personalized support required for unique foot structures.

The Growing Search Trend for Plantar Fasciitis

An important aspect to note is the increasing public interest in plantar fasciitis. Recent search data reveals that worldwide, there are between 40 to over 100 daily searches specifically related to “Plantar Fasciitis.” This steady increase in search volume highlights that more people are looking for information and solutions for this condition every day. It emphasizes the urgent need for innovative solutions—such as 3D printed orthotics—to address this growing problem.

Traditional Orthotics: Methods and Limitations

Traditional orthotics are produced using time-tested manual methods. Skilled technicians create a physical cast of your foot using plaster, which is then used to form a custom insole. Although reliable, this method has several limitations:

Infographic: How Traditional Orthotics Are Made & Their Drawbacks

Traditional Orthotics Process

Traditional Orthotics: Drawbacks (Side-by-Side Comparison)

Conventional Craftsmanship and Materials:

- • Manual Casting and Molding: Plaster or foam captures the foot’s shape.

- • Standard Materials: Typically include rigid plastics or foams that may not perfectly match your foot’s biomechanics.

Drawbacks and Challenges:

- • Long Turnaround Times: Custom orthotics can take several weeks to produce.

- • Higher Labor Costs: The labor-intensive process increases overall costs.

- • Limited Customization: Manual methods may not capture subtle variations in foot structure, reducing the effectiveness of the orthotic.

Example: Patients often report moderate relief with traditional orthotics; however, the fit may not be precise, leading to recurring discomfort or the need for adjustments.

The 3D Printing Revolution in Orthotic Care

Advancements in 3D scanning and printing have paved the way for custom, on-demand orthotics that provide a breakthrough in personalization and efficiency.

Cutting-Edge Customization and Precision:

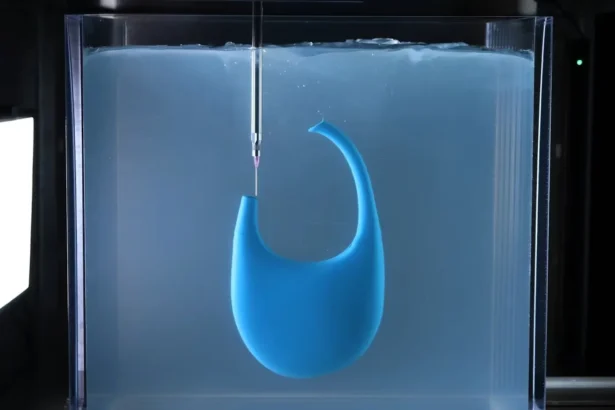

3D printed orthotics begin with a digital scan of your foot, capturing every curve and pressure point with high accuracy. This data is then used to design and print a bespoke orthotic that is tailored precisely to your unique needs.

Key Advantages:

- • Unmatched Precision: Digital scans ensure every anatomical detail is captured.

- • Rapid Production: Turnaround times drop from weeks to mere hours, sometimes even same-day production.

- • Dynamic Fit: Orthotics adapt to foot movements throughout the day.

Material Innovation:

3D printing enables the use of lightweight, durable, and flexible materials. These materials provide better shock absorption and long-lasting support compared to traditional orthotic materials.

Real-World Example: Companies such as Voxelcare and Shapecrunch use advanced digital scanning and 3D printing technology to produce orthotics designed specifically to target conditions like plantar fasciitis.

Top Companies Leading the 3D Printed Orthotics Revolution

As the digital revolution reshapes foot care, several companies are at the forefront of using 3D printing technology to create custom orthotics for conditions like plantar fasciitis. These industry leaders are delivering innovative, precise, and rapid solutions that offer a compelling alternative to traditional methods.

Voxelcare (via ALGEOS)

Voxelcare leverages advanced digital scanning and 3D printing technology to craft highly precise, custom orthotics. Their process ensures that every curve and pressure point of your foot is captured, resulting in an orthotic that delivers superior comfort and support. Visit algeos.com to learn more.

Shapecrunch

Shapecrunch specializes in combining digital scanning with sophisticated computer vision to design custom orthotic insoles. Their technology targets conditions like plantar fasciitis directly, offering tailored solutions that adjust to your unique foot biomechanics. Check out their offerings at shapecrunch.com.

OLT Footcare

OLT Footcare is revolutionizing in-clinic solutions by enabling practitioners to use smartphone scans for 3D printing custom orthotics on-site. With a focus on rapid turnaround times and personalized design, OLT Footcare helps patients receive effective orthotic treatment quickly. Discover their services at oltfoot.com.

Arize Custom Orthotics

Working closely with podiatrists, Arize Custom Orthotics produces thin, lightweight, and highly engineered 3D printed orthotics. Their collaboration with medical professionals ensures that each orthotic is designed with both functionality and patient comfort in mind. Learn more at northeastfoot.com.

ScientiFeet

Based in Canada, ScientiFeet offers bespoke 3D printed orthotic solutions crafted from patient-specific foot data. Their approach emphasizes precision and durability, ensuring a customized fit that significantly enhances pain relief and mobility. Explore their innovative approach at scientifeet.com.

By considering these top companies, you can explore cutting-edge 3D printed orthotic solutions that are shaping the future of foot care. Each provider offers unique benefits designed to deliver fast, precise, and comfortable orthotic options tailored to your needs.

Comparative Analysis: Traditional vs. 3D Printed Orthotics

When evaluating which approach offers the best relief for plantar fasciitis, consider the following factors:

1. Speed and Turnaround

- • Traditional Orthotics: Production can take 3-4 weeks due to manual casting and labor-intensive fabrication.

- • 3D Printed Orthotics: Digital scanning and automated printing can reduce production time to just a few hours, allowing for rapid relief.

2. Precision and Customization

- • Traditional Methods: Reliant on manual casts, which may miss subtle anatomical variations.

- • 3D Printed Solutions: Utilize digital imaging for a highly tailored fit that adapts to individual biomechanics.

3. Cost and Material Innovation

- • Traditional Orthotics: Generally more expensive due to higher labor costs and material waste.

- • 3D Printed Orthotics: More cost-effective with scalable production processes and sustainable materials.

4. Patient Outcomes and Satisfaction

Comparative case studies suggest that patients using 3D printed orthotics experience quicker recovery and enhanced comfort compared to those using traditional methods.

Expert Opinions and Future Trends

Industry experts are increasingly embracing 3D printing as a solution for plantar fasciitis. Key insights include:

- • Personalized Medicine: Tailoring orthotics to individual anatomy is a major advancement in patient care.

- • AI Integration: Emerging AI-driven design tools are set to further refine 3D printed orthotics.

- • Hybrid Approaches: Combining traditional craftsmanship with digital innovation may offer the best of both worlds.

Conclusion: The Future of Plantar Fasciitis Treatment

Given the growing daily search volumes—40 to over 100 searches per day worldwide—and the increasing public awareness of plantar fasciitis, there is a clear demand for more effective, personalized solutions. 3D printed orthotics offer distinct advantages in speed, precision, cost-effectiveness, and patient satisfaction compared to traditional methods.

Final Recommendations:

- • Opt for 3D Printed Orthotics: For those seeking a fast, precise, and comfortable solution.

- • Consult Healthcare Professionals: Personalized evaluation is key to choosing the best treatment option.

- • Stay Informed: Keep an eye on emerging digital technologies that are continually improving foot care.

By incorporating digital innovation into foot care, 3D printing companies can help meet the growing demand for effective plantar fasciitis treatments, ultimately improving patient outcomes and reducing the burden of this widespread condition.

References and Sources

- • ALGEOS – Information on advanced 3D printed orthotic solutions.

- • Shapecrunch – Details on custom orthotic production using digital scanning.

- • KURU Footwear – Statistical data and trends related to plantar fasciitis.

- • Harvard Health – Overview of symptoms, causes, and treatments for plantar fasciitis.

- • AAFP – Clinical practice guidelines for heel pain and plantar fasciitis.

Note: Daily search volume data is based on industry analytics and trends, reflecting that between 40 to over 100 searches for “Plantar Fasciitis” occur worldwide each day. This growth in search interest underscores the increasing public concern about this condition and the need for innovative treatments.