Introduction: Why 2025 Is the Tipping Point for Additive Manufacturing

Additive manufacturing has flirted with the mainstream for more than a decade, but 2025 is the first year it’s shipping finished products—at scale. Laboratory curiosities such as self-healing foams, color-shifting smart polymers, and AI-generated shoes are now leaving poster sessions and hitting store shelves, surgical suites, and factory floors.

In this guide, we unpack eight headline breakthroughs—from recyclable polymers to tree-inspired “growth printing.” For each innovation you’ll learn what happened, why it matters, and how soon it could hit mass production, helping designers, engineers, investors, and curious consumers stay well ahead of the curve.

1. Sustainable & Circular Materials Revolution

1.1 Recyclable, Self-Healing Polymer Foam

Researchers at The University of Texas at Dallas unveiled a 3D-printable foam that heals itself via dynamic covalent chemistry—the reversible bonds found in advanced hydrogels. A quick blast of UV or mild heat “rewelds” torn lattices, restoring up to 90 % of the original strength.

Why it’s a breakthrough

- Landfill relief: Most foams are thermoset; this one can be ground, mixed with fresh resin, and re-printed.

- Performance boost: Gyroid lattices absorb 15–25 % more impact energy than conventional EVA midsoles.

- Target markets: Running shoes, bike helmets, aerospace dampers, premium mattresses.

Next step: UT Dallas has filed patents and is courting athletic brands—expect premium insole pilot runs by late 2026.

1.2 Biodegradable PHA Footwear Prototypes

The O° (“Zero”) platform from OXMAN combines robotic 3D-knitting with multi-material printing to craft shoes from microbe-grown PHA—a bioplastic that composts in seawater within months.

- Seam-free uppers knit from PHA yarn; lattice midsoles printed from stiffer PHA blends.

- Organic pigments grown by bacteria—no toxic dyes or glues.

- Challenges: global PHA output < 100 kt/year and raw cost (~ $6 kg) is still double TPU.

Luxury and eco-athleisure labels are lining up for a limited drop in 2026.

1.3 Recycled Leather Filament (ECOFAP)

Europe’s ECOFAP consortium micronizes tanned leather off-cuts, blends the powder with bio-polymer, and extrudes a 1.75 mm filament that prints like soft PLA.

- Diverts thousands of tons of leather scrap from landfill.

- Retains leather’s warmth while enabling lattices impossible in molding.

- Early testing shows 30 % higher tear strength than recycled TPU.

Pilot lines in Spain already print heel counters and bag panels—perfect story for Gen-Z shoppers demanding circular fashion.

2. Medical & Bio-Printing Milestones

2.1 Elastic Hydrogel for 3D-Printed Organs

Bioengineers at Northeastern University created an elastic hydrogel that stretches 500 % and snaps back like artery tissue. Printed vessels remain intact under pulsatile flow, while peptide linkers encourage endothelial cells to colonize the channels.

- Solves the brittleness that plagues many bio-inks.

- In-vivo animal trials scheduled for 2026; goal is transplant-grade organs within a decade.

3. Smart & High-Performance Functional Materials

3.1 Color-Changing Cholesteric LCEs (CLCE)

Penn Engineering used coaxial direct-ink-writing to print filaments whose helices reflect different colors when stretched. A silicone shell adds durability without muting the optical shift.

- Wearable diagnostics: A shoe tongue that flashes red at risky strain levels.

- Medical bandages: Visual swelling indicators.

- Sports-tech licensing deal in the works—watch for concept cleats ahead of the 2028 Games.

3.2 MXene Micro-Printing at 1.3 µm Resolution

South Korea’s KERI pushed 3D-printing resolution to 1.3 µm by jetting water-dispersed MXene nanosheets—no binders, no sintering.

- Perfect for mm-wave antennas in AR glasses, stretchable biosensors, and lab-on-chip diagnostics.

- Withstands 140 % strain—comparable to silver inks at one-tenth the cost.

A smartphone giant is already funding an on-lens antenna feasibility study.

4. Next-Gen Manufacturing Processes

4.1 “Growth Printing” via Frontal Polymerization

Inspired by tree rings, UIUC’s Beckman Institute injects a seed of liquid DCPD that solidifies outward at ~ 1 mm/s—roughly 100× faster than FDM or SLA.

- Energy-light: Exothermic cure slashes heater power draw.

- Size freedom: Parts can exceed printer bounds—think surfboards, wind-turbine blades.

Large-part prototyping times can fall from months to days, a game-changer for marine and aerospace giants.

Beckman Institute press release →

5. Consumer-Grade Product Breakthroughs

5.1 Adidas’ Fully 3D-Printed Climacool Sneaker

On May 2 2025, Adidas launched the first fully printed sneaker at global retail—a seamless Climacool made with Carbon’s DLS resin. MSRP: $120; factory cost $28.

- Lattice upper + midsole in one piece eliminates gluing and most labor.

- Ventilated design fixes the squeak problems of earlier 4D shoes.

5.2 AI-Designed Custom Slides (Syntilay Xplorer)

Syntilay shrinks design cycles from six months to under ten days by pairing MidJourney concept art with Vizcom CAD and Zellerfeld full-shoe printers. Each pair is fit to a smartphone foot scan; delivery in 5 weeks for $149.

- Entire inventory lives in the cloud—zero unsold SKUs.

- Current capacity (a few thousand pairs) shows tech limits today and growth upside tomorrow.

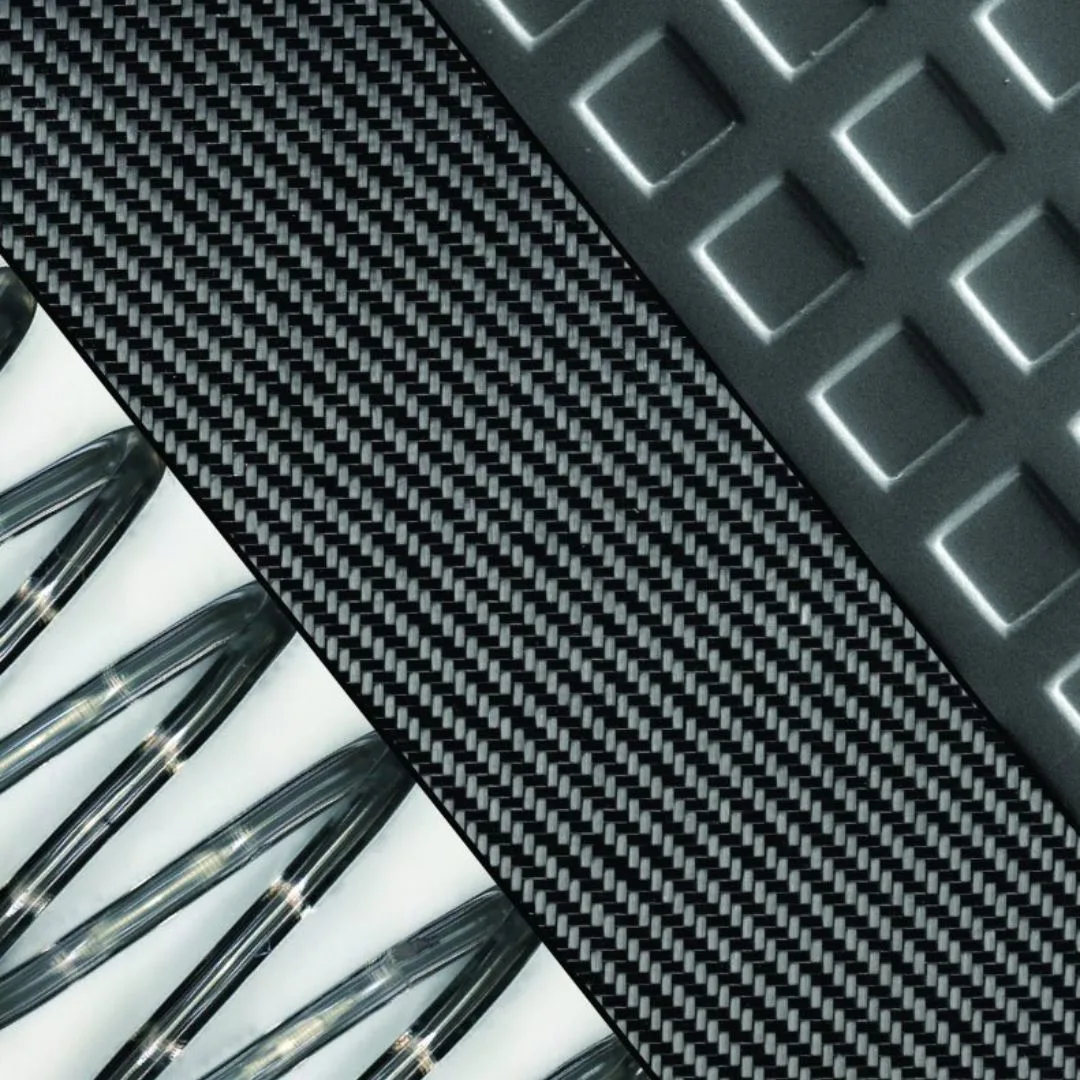

5.3 Lore Two Custom Cycling Shoe

By combining a rigid carbon 3D shell with a flexible TPU wrap, Lore Cycle and Lubrizol give cyclists a 3 % power-transfer boost plus glove-like comfort—at $1,200 a pair. The success proves pros will bankroll additive gear that earns podiums.

6. What These 2025 Breakthroughs Mean for 2025–2030

| Trend | Impact | Who Should Act |

|---|---|---|

| Faster Time-to-Market | AI design + growth printing compress dev cycles by 10× | Brands chasing quarterly drops |

| Mass Personalization | Batch-size-one prices approach mass-production costs | Footwear, medical devices, e-bikes |

| Circular Economy | Regulators target single-use plastics; recyclable foams and PHA shoes answer the call | Sustainability officers, investors |

| Electro-Bio Convergence | MXene circuits + elastic hydrogels blur gadget vs. tissue | Med-tech startups, sensor OEMs |

| Capital Accelerates | Adidas & Lubrizol ink eight-figure deals | VCs and corporates scouting acquisitions |

Conclusion: Gear Up for the Additive Decade

2025 marks the end of “prototype-only” 3D printing. Self-healing lattices, compostable sneakers, vascular hydrogels, and micron-scale circuits show that additive manufacturing now rivals—or beats—legacy methods on cost, speed, and sustainability.

Whether you design next-gen wearables, manage supply-chain risk, or scout high-growth investments, the coming winners will be those who adopt these 3D printing breakthroughs 2025 before the competition does.

Stay Up to Date

Sign up for 3DShoes.com’s mailing list to get the latest 3D-printing breakthroughs, sneaker drops, and industry trends—delivered straight to your inbox. No spam, no PDF downloads to chase—just the news and insights you care about.

FAQ — Quick Answers on 3D Printing Breakthroughs 2025

The fully 3D-printed Adidas Climacool sneaker is the year’s most tangible proof that additive manufacturing can hit mass-retail price points (costing only ≈ $28 to make). It signals that consumer brands can now scale additive production profitably.

Pilot insoles and helmet liners are expected by late 2026, once UT Dallas finalizes material certification and signs manufacturing partners. Full midsoles should follow as costs fall.

Yes—under typical backyard-compost conditions, PHA breaks down in 3–6 months. Industrial composting or ocean water speeds the process, but avoid landfills, where decomposition is slower due to low oxygen.

Not yet. The UIUC/Beckman process is still lab-scale. Expect early aerospace or marine prototypes in 2026–2027, with commercial tooling adoption once resin formulations and QC standards mature.

At 1.3 µm resolution, MXene traces can pack far higher antenna density, remain flexible up to 140 % strain, and require no high-temperature sintering—making them ideal for wearables and AR glasses.

Paradoxically, no. AI shortens concept-to-CAD time from months to days, reducing R&D overhead. While bespoke models like Syntilay’s slides cost ~$150 today, prices should drop as printer throughput rises.

Footwear & sporting goods: mass-custom shoes and protective gear.

Medical devices: bioprinted tissues and patient-specific implants.

Aerospace & marine: large composite parts via growth printing.

Consumer electronics: flexible MXene circuits and on-lens antennas.

Begin with low-risk pilots: lattice insoles, custom grips, or jigs printed from recyclable foam. Partner with service bureaus already certified for medical or aerospace materials, and subscribe to research feeds so you’re alerted as new resins or equipment exit beta.