Purdue University is redefining the future of diagnostics and research with its breakthrough in 3D printing microfluidic devices. This patent-pending engineering technology harnesses a novel vat photopolymerization (VPP) method, combined with cutting-edge LCD-based ultraviolet exposure, to fabricate tiny multilevel microfluidic devices with unprecedented precision. This innovation not only streamlines production but also promises to revolutionize biomedical research, environmental testing, manufacturing, and more.

A New Era in Microfluidic Device Fabrication

Microfluidic devices—compact systems that manipulate minute volumes of fluids—are critical for applications ranging from single-cell analysis to rapid diagnostic testing. By channeling fluids through networks of microscopic channels, these devices enable high-throughput screening and precise control of chemical reactions. Traditionally, manufacturing these devices has been both costly and complex, involving expensive cleanroom facilities and labor-intensive processes.

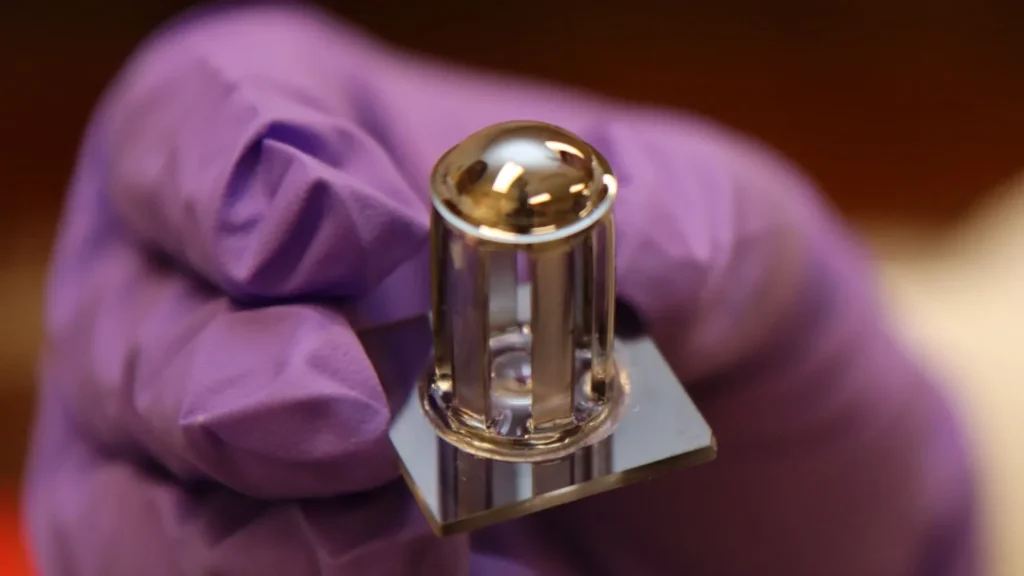

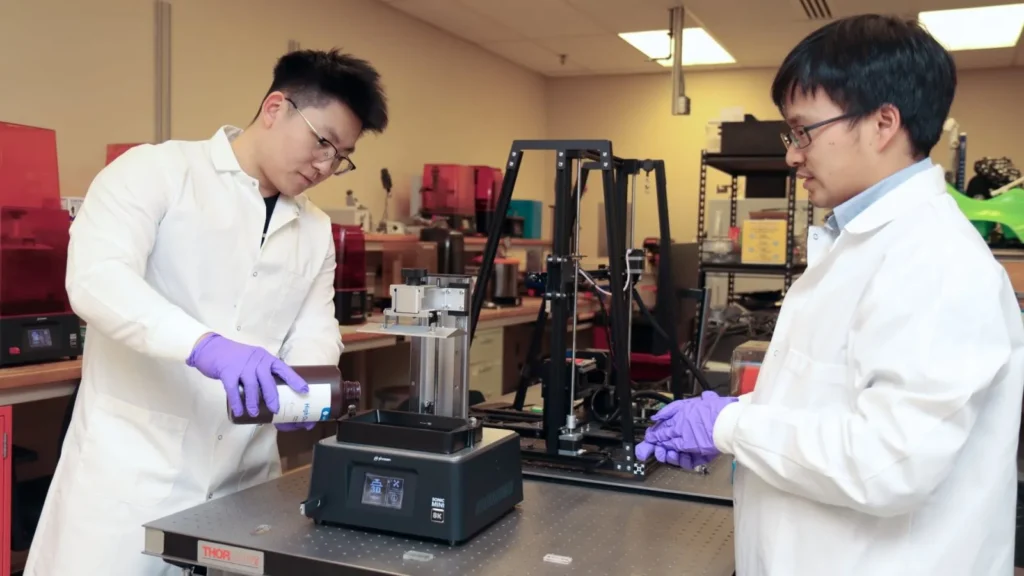

Purdue University’s research team, led by Assistant Professor Huachao Mao at the Purdue Polytechnic Institute, has developed a breakthrough that bypasses these constraints. Their innovative approach allows for the creation of devices as small as 10 microns deep and 100 microns wide, effectively overcoming the limitations of previous 3D printing techniques that struggled with channels narrower than 500 microns.

The Technology Behind the Breakthrough

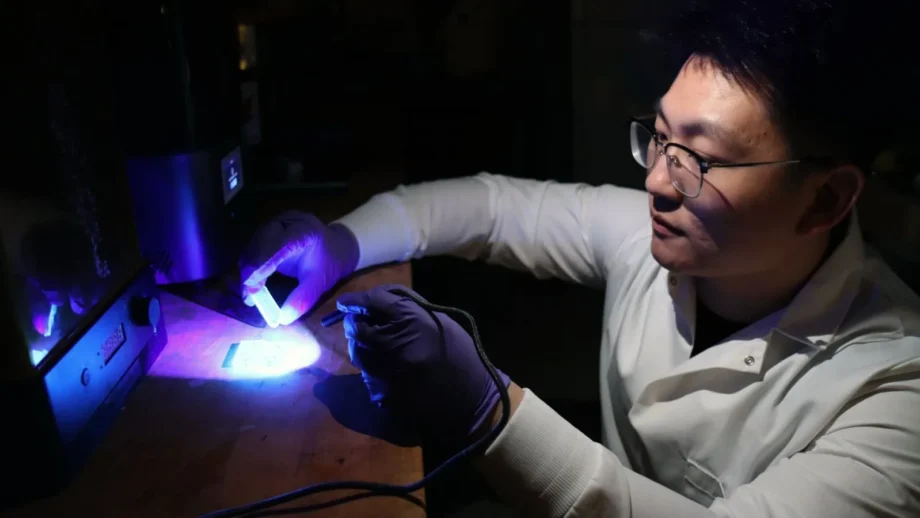

At the heart of this innovation is a patent-pending process based on vat photopolymerization (VPP), a method that constructs devices layer by layer from a liquid photopolymer resin. By employing an advanced LCD-based UV exposure technique, the system achieves high-resolution channel formation without the need for expensive high-end equipment or cleanroom environments.

Key advantages of this technology include:

- • High Resolution: The method produces highly transparent microfluidic channels with widths as narrow as 100 microns. This is critical for applications requiring the isolation of single cells or precise fluid dynamics.

- • Cost Efficiency: By eliminating the need for multiple fabrication steps and high-end lasers, production costs drop dramatically—making advanced microfluidics accessible to more research labs and industries.

- • Rapid Production: The streamlined process allows for quicker prototyping and production, accelerating the pace of research and innovation.

According to Mao, “VPP allows for the direct fabrication of microfluidics with a much higher resolution. An emerging method within VPP is the use of LCD technology, which uses ultraviolet light to facilitate photopolymer solidification in a highly controlled manner.”

Applications Across Multiple Industries

The ability to create such precise microfluidic devices opens a world of possibilities:

- • Biomedical Research: The technology can isolate single cancer cells, facilitating breakthroughs in personalized medicine and early disease detection. Rapid drug screenings and point-of-care diagnostics become feasible with portable, high-precision devices.

- • Environmental Testing: Researchers can now analyze minute sample volumes quickly, allowing for real-time monitoring of water quality and pollutant levels.

- • Manufacturing and Quality Control: Incorporating these devices into industrial systems enables on-demand testing and improved process control, enhancing product quality.

- • Geology and Materials Science: Microfluidics can simulate the flow of fluids through porous materials, offering valuable insights into natural and engineered systems.

By addressing long-standing fabrication challenges, Purdue’s innovation not only accelerates research timelines but also has the potential to democratize access to advanced diagnostic tools.

Validation, Future Research, and Commercialization

Validation of the new technology has already been demonstrated by successfully printing microfluidic channels that can form single lines of cancer cells—an achievement that showcases its potential in real-world diagnostic applications. The research team has also fabricated complex networks mimicking natural capillary structures, further underscoring the versatility of this method.

Looking ahead, the team plans to integrate these 3D-printed devices with conventional 2D nanofabrication techniques to combine the best features of both methods. Such hybrid systems could further expand the applications of microfluidics in both research and clinical settings.

Purdue Innovates Office of Technology Commercialization has taken proactive steps to protect this groundbreaking technology through patent applications (track code 69871). Industry partners interested in collaboration or commercialization can contact Parag Vasekar, OTC Business Development and Licensing Manager, at psvasekar@prf.org.

The Role of John O’Malley: Documenting Purdue’s Innovation

John O’Malley, Senior Digital Media Specialist at Purdue Polytechnic Institute, has played a pivotal role in bringing this story to life. With decades of experience in digital media and technical communication at Purdue, John’s expertise in capturing and editing news content has helped showcase Purdue’s cutting-edge research to a global audience.

A Purdue staffer since 1990, John joined Purdue Polytechnic in March 2014 and has since been instrumental in producing news articles, promotional videos, and engaging social media content that highlights the university’s innovations. To learn more about John’s work and connect with him, visit his Purdue profile or connect on LinkedIn.

Expert Opinions and Case Studies

Purdue’s innovative method has already attracted attention from experts and industry leaders. Detailed case studies presented at the ASME International Mechanical Engineering Congress and Exposition and research published by other institutions further validate the technology’s applicability in single-cell analysis and complex network formation.

Case Study 1: Single-Cell Analysis for Cancer Research

Researchers at Brigham Young University demonstrated the use of microfluidic devices with sub-100 micrometer channels for isolating and analyzing individual cancer cells. This approach, showcased at the ASME International Mechanical Engineering Congress, enabled precise measurement of cellular responses to chemoattractants—an application directly comparable to Purdue’s use in single-cell analysis of cancer cell lines. Gregory Nordin, a professor at BYU, noted, “The ability to fabricate microchannels small enough to study single-cell behavior offers unprecedented insights into cellular heterogeneity, which is critical for advancing personalized medicine” (ASME Digital Collection).

Case Study 2: Integration with Fluorescence Microscopy for Dynamic Protein Localization

A study reported on 3D Printing Breakthrough Creates Tiny Microfluidic Devices at Record Scale from 3DPrinting.com demonstrated how 3D printed microfluidic devices can be integrated with fluorescence microscopy to monitor dynamic protein localization. The high-resolution channels enabled real-time visualization of fluorescently labeled proteins within single cells, reinforcing the device’s potential for advanced biomedical applications (3DPrinting.com).

Case Study 3: Complex Network Formation in Microfluidic Devices

In a dissertation available through BYU ScholarsArchive, Michael J. Beauchamp demonstrated the development of 3D printed microfluidic devices for bioanalysis. His work, which involved fabricating intricate channel networks to mimic natural capillary systems, provided robust evidence for the effectiveness of 3D printed molds in replicating complex network geometries. This research supports the potential of Purdue’s technology to reproduce physiologically relevant microenvironments (BYU ScholarsArchive).

These case studies, along with expert testimonials, validate that Purdue’s technology is not only innovative but also practical for real-world applications in personalized medicine and high-throughput biomedical research.

Embracing the Future: Why This Innovation Matters

This breakthrough in 3D printing microfluidic devices is more than just a technological feat—it represents a paradigm shift in how research and manufacturing challenges are approached. By enabling faster, more precise, and cost-effective production of microfluidic devices, Purdue University is paving the way for new discoveries in medicine, environmental science, and beyond.

Researchers, industry professionals, and technology enthusiasts are encouraged to explore the potential of this technology further. The convergence of advanced 3D printing methods with traditional microfluidic techniques could lead to unprecedented innovations, making this an exciting time for all stakeholders involved.

Next Steps and Engagement

If you are a researcher, industry professional, or simply intrigued by the potential of 3D printing microfluidic devices, now is the time to delve deeper. Stay informed about the latest developments from Purdue University by following their Newsroom and the Purdue Polytechnic Institute. For collaboration or licensing opportunities, reach out directly to Parag Vasekar at psvasekar@prf.org.

Join the conversation on social media, subscribe to newsletters, and be a part of the transformative journey that is reshaping the future of diagnostics and advanced manufacturing.

Conclusion

Purdue University’s patent-pending innovation in 3D printing microfluidic devices represents a major leap forward in manufacturing and diagnostic technology. By overcoming the limitations of traditional fabrication methods, this breakthrough not only accelerates research and development but also broadens the accessibility of high-precision microfluidic devices. With its successful validation and promising future research directions, Purdue is set to lead a new era of innovation that will transform multiple industries. Embracing this technology today means preparing for a smarter, faster, and more efficient tomorrow.

Sources

- 1. Purdue Newsroom:

Purdue printing innovation fabricates multilevel microfluidic devices as small as 10 microns deep

https://www.purdue.edu/newsroom/2025/Q1/purdue-printing-innovation-fabricates-multilevel-microfluidic-devices-as-small-as-10-microns-deep/ - 2. Purdue Polytechnic Institute:

John O’Malley’s Profile

https://polytechnic.purdue.edu/profile/omalley - 3. Purdue Research Foundation News:

https://www.prf.org/news/ - 4. 3DPrinting.com:

3D Printing Breakthrough Creates Tiny Microfluidic Devices at Record Scale

https://3dprinting.com/news/3d-printing-breakthrough-creates-tiny-microfluidic-devices-at-record-scale/ - 5. BYU ScholarsArchive:

3D Printed Microfluidic Devices for Bioanalysis

https://scholarsarchive.byu.edu/etd/8566

Media Contact

For further inquiries, please contact:

- • Steve Martin, Media Contact, Purdue News, at sgmartin@prf.org

- • John O’Malley, Senior Digital Media Specialist, Purdue Polytechnic Institute, at omalley@purdue.edu