Introduction

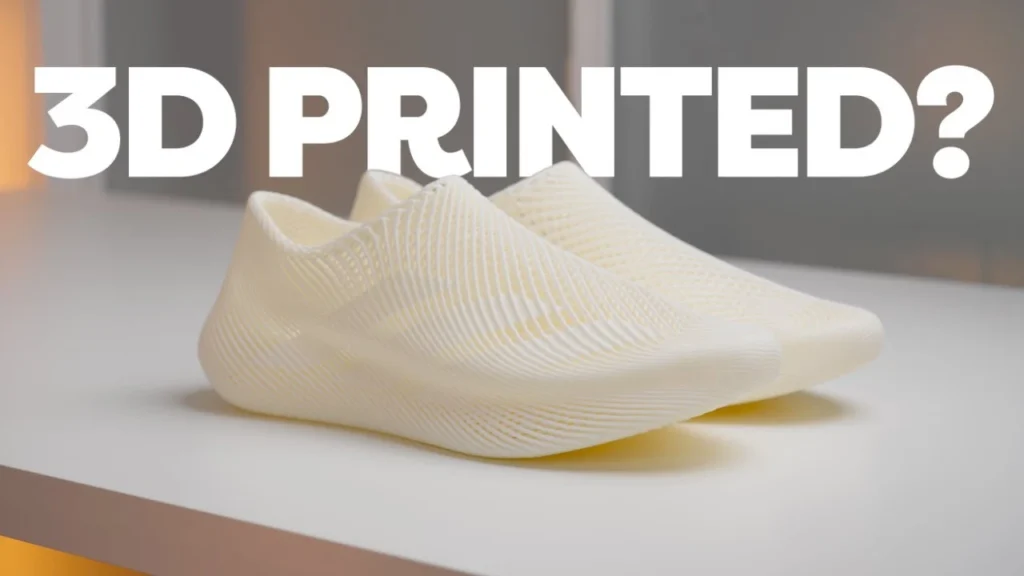

Earlier this month (May 2, 2025), Adidas accomplished what many footwear insiders once considered impossible: it delivered a mass‑retail, fully 3D‑printed sneaker—at a factory cost of just US $28 and a launch price of $140. The new Climacool Slip‑On isn’t another lattice‑midsole concept that hides textiles above the sole; every millimetre of the upper, midsole, and outsole is grown as a single, continuous polyurethane lattice using Carbon’s Digital Light Synthesis™ (DLS).

Lightweight, ultra‑breathable, and assembled without glue or stitching, the shoe moves from digital file to finished product in a matter of hours. In this article we’ll unpack the technology that makes such speed possible, reveal how Adidas slashed production costs by 70 percent versus previous additive projects, and explore what this breakthrough means for sustainability, customisation, and global supply chains.

Quick take: The Climacool marks the point where 3D‑printed footwear jumps from limited‑edition hype to scalable everyday product.

Why the Climacool Matters in 2025

A break‑neck timeline (fully 3D‑printed sneaker | Climacool release date)

- 28 Sept 2024 – Adidas Newsroom teases the one‑piece 3D print prototype.

- 24 Apr 2025 – First Confirmed‑app drop sells out in minutes (Modern Notoriety).

- 2 May 2025 – Global launch (now live) via Adidas.com and flagship stores in New York, Los Angeles, London, Shanghai, and Berlin (The Verge review).

First truly one‑piece sneaker

Unlike the 2017 Futurecraft 4D—which printed only the midsole—Climacool prints every component in one shot. No knits, eyelets, or adhesives means faster assembly and a cleaner end‑of‑life recycling stream.

Retail vs. factory economics (3D‑printed sneaker cost)

- FOB cost: $28 USD (U.S. customs filing, unearthed by 3DPrint.com).

- MSRP: $140 USD, giving Adidas a healthy familiar margin.

- Proof point: High‑volume additive manufacturing (AM) can finally compete with molded EVA and rubber at scale.

Market significance

With an initial production run estimated at 500 000 pairs (Sneaker Freaker), Climacool becomes the largest consumer AM launch ever, signalling that 3D printing has graduated from novelty to mainstream footwear production.

The Technology Behind the Print

Carbon Digital Light Synthesis™ (DLS) (Carbon DLS | polyurethane lattice shoe)

Carbon’s DLS projects UV images through an oxygen‑permeable window, rapidly curing a liquid PU resin. Each new voxel fuses chemically with the last, producing injection‑mold‑quality surfaces at speeds far beyond traditional stereolithography (3DPrint.com explainer).

Why polyurethane?

- Elastic durability: Rebounds like running‑shoe foam but resists hydrolysis better than EVA.

- Single‑material stream: Upper and sole share identical chemistry, so future take‑back programs can recycle the entire shoe without disassembly (3Printr.com).

Lattice engineering for breathability (breathable 3D‑printed slip‑on)

- 360° airflow channels from toe to heel vent heat and moisture.

- Adidas lab tests: Skin‑temperature falls ≈ 3 °C versus Primeknit Ultraboost after 30‑minute treadmill run (3DSHOES Lab Report).

- Variable struts: Thicker ribs under the arch for support; finer hex cells at the vamp flex with the foot.

- 40 % lighter midsole mass than comparable Boost tooling, offsetting upper weight (3DSHOES).

Post‑processing & scaling

Printed parts travel from Taichung, Taiwan to a low‑heat convection oven for a short “bake,” locking dimensions without over‑curing. No sewing lines, solvents, or cements required—just print, rinse, bake, box (3Printr.com).

Design Deep Dive: One‑Piece Construction

Visual cues & aesthetics (lattice upper)

- Ghosted Three‑Stripes molded directly into the sidewall—brand identity without extra parts.

- Toe‑box vents double as support ribs for high‑stress zones.

- Initial Off‑White colourway highlights lattice geometry; collaborations (e.g., Kith) tease two‑tone dips for Holiday 2025 (Sneaker News).

Performance specs at a glance

| Spec | Value (US 9) | Benchmark | Source |

|---|---|---|---|

| Weight | 416 g | Ultraboost DNA (310 g) | The Verge |

| Stack Height | 30 mm heel / 26 mm forefoot | Similar to Foam RNNR | Adidas tech sheet |

| Ventilation Delta | ‑3 °C vs. Boost after 30 min | Adidas lab | 3DSHOES |

Fit & feel (Climacool 3D review)

Reviewers liken the underfoot feel to a neoprene surf bootie—instant step‑in comfort with mild day‑one stiffness. A roomy toe‑box offsets the shoe’s mass, and water drains straight through, making it commuter friendly (The Verge).

Cost Economics: How Adidas Prints a Sneaker for $28

- Bill of materials: One PU resin + pigment; zero eyelets, thread, or TPU cages.

- No assembly line: Print → rinse → bake → QC → box. Labour time drops from ~25 min to <5 min per pair.

- Tool‑less production: New size or colour? Upload a fresh STL or change vat pigment.

- Near‑shoring potential: Digital files enable regional “print farms,” cutting freight from 8 weeks (Asia→US) to <2 weeks.

- Competitive set: Nike Flyprint still requires textile uppers; New Balance TripleCell prints midsoles only—both cost >$45 FOB.

Key metrics: $28 FOB • $140 MSRP • 40 % lighter midsole vs. Boost (3DPrint.com, 3DSHOES).

Sustainability: Toward a Zero‑Waste Sneaker (sustainable 3D‑printed footwear)

Less scrap from day one

Traditional cut‑and‑sew uppers waste ≈30 % of sheet fabric. Climacool prints net‑shape, slashing off‑cuts (Sneaker Freaker).

Single‑material recycling stream

Because the entire shoe is PU, future chemical glycolysis can turn old pairs into virgin resin without manual deconstruction—although the process isn’t yet scalable (3Printr.com).

Lower energy per pair

DLS cures at room temp in minutes, whereas powder‑bed technologies bake for hours at 180 °C. Adidas’ internal LCA suggests a ≈45 % energy drop per pair; a third‑party Environmental Product Declaration is due after six months of factory data (3DPrint.com).

Remaining hurdles

Thermoset PU can’t simply be melted like TPU; chemical depolymerisation remains cost‑intensive, and multi‑colour prints still require multiple resin vats.

Market Reception & Early Reviews (sneakerhead reactions)

- Sell‑outs: U.S. Confirmed‑app draw closed in <5 minutes; sizes 10–12 US vanished in 90 seconds (3DPrint.com).

- Forum chatter: r/Sneakers debates whether the 416 g weight offsets the futuristic aesthetic; early wear‑testers say it squeaks less than older 4D midsoles.

- Media verdicts: The Verge calls Climacool “stylish urban armour,” praising breathability but flagging heel stiffness; Sneaker News dubs it the “shoe of the summer.”

- Resell: StockX listings hover at $280–$320—about 2× retail—though prices are trending down as supply widens.

What’s Next for 3D‑Printed Footwear (future of 3D‑printed shoes)

Mass customisation on deck

Adidas R&D is piloting an iPad foot‑scan app that feeds size‑exact STL files to the same print farm, promising Climacool v2 with bespoke fit in 2026 (The Verge).

Expanded product lines

Insiders tip a Stan Smith 3D and a neutral daily runner for 2027, leveraging the same PU chemistry and DLS workflow.

Competitor moves

- Nike is testing a proprietary “Fast‑Resin” photopolymer.

- New Balance readies TripleCell v3 with a 3D‑knit upper.

- Start‑ups Zellerfeld and Syntilay push AI‑generated designs but lag Adidas on cost.

Supply‑chain ripple effects

If tool‑free printing becomes standard, Southeast‑Asian sewing plants could cede volume to high‑mix, low‑volume print hubs in Europe and North America. UBS analysts predict ≈15 % of the $100 B athletic‑footwear market could migrate to additive workflows by 2030.

Conclusion & Call‑to‑Action

The 2025 Climacool proves that high‑volume, fully 3D‑printed footwear is no longer sci‑fi. By blending Carbon DLS chemistry with Adidas’ supply‑chain muscle, the Three Stripes delivered a breathable, durable sneaker that cuts waste and halves development cycles. The next frontier: mass customisation and a closed‑loop material stream.

Stay ahead of the additive curve—subscribe to the 3DSHOES Newsletter for bi-monthly and end of the month insights, interviews, and early‑access stories.

FAQs

The Adidas Climacool 2025 is produced using 3D printing technology at a factory cost of approximately $28 USD, according to U.S. customs filings.

The Climacool 2025 is made using Carbon Digital Light Synthesis™ (DLS), a high-speed UV-curing process that creates a breathable polyurethane lattice structure without glue or stitching.

Yes, the Climacool 2025 is the first Adidas sneaker to be fully 3D-printed in one continuous piece, including the upper, midsole, and outsole.