Introduction: The Future of Fabrication Begins Here

Imagine creating a complex metal part where one section is optimized for heat conduction and another for mechanical strength—all printed in a single build. This is the transformative promise of Multi-Material Laser Powder Bed Fusion (MM-LPBF).

While traditional 3D printing revolutionized prototyping and manufacturing, MM-LPBF is the next frontier, enabling multi-functional, spatially tailored components to meet demanding applications across aerospace, biomedicine, energy, and beyond.

In this guide, we’ll break down what MM-LPBF is, how it works, its benefits and limitations, and explore real-world applications. By the end, you’ll understand why MM-LPBF is more than just an innovation—it’s a leap forward in metal additive manufacturing.

What Is Multi-Material LPBF?

Multi-Material Laser Powder Bed Fusion (MM-LPBF) is an advanced metal 3D printing technology that enables the layer-by-layer fusion of two or more metals in a single build. Unlike conventional LPBF—which uses one metal powder at a time—MM-LPBF leverages Selective Powder Deposition (SPD) to position and fuse different powders with precision, based on a digital 3D model.

Key Differences from Standard LPBF:

- Standard LPBF: Uses one material throughout the part.

- MM-LPBF: Combines multiple metals in a single structure, each with region-specific properties.

Common Material Pairings:

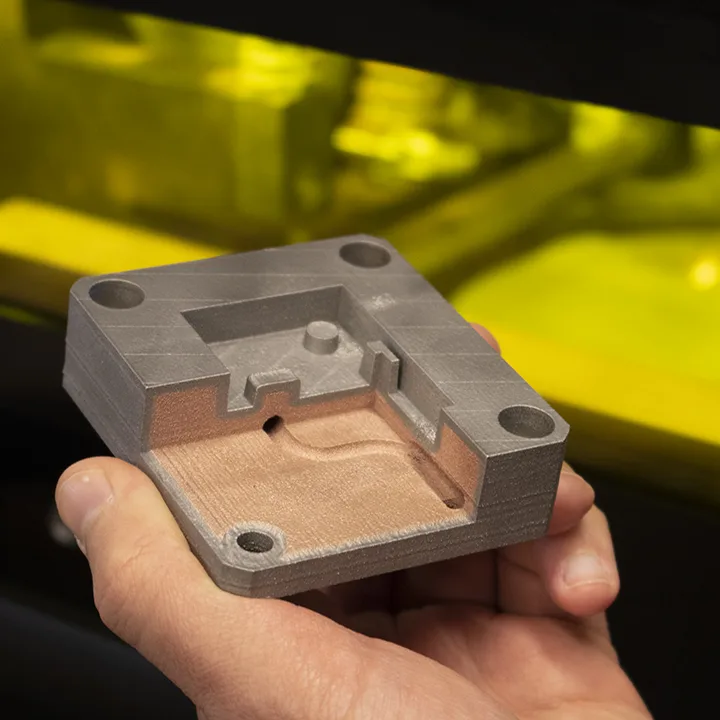

- Stainless Steel + Bronze: Strength with conductivity.

- Titanium + Tantalum: Ideal for biomedical implants.

- Tool Steel + Copper: Useful in mold tooling with embedded cooling.

Recent research by Griffis et al. (2025) has shown that MM-LPBF can successfully fuse these materials when process parameters are optimized for each metal’s thermal characteristics, reinforcing the importance of material science in this technology.

How Multi-Material 3D Printing Works

The MM-LPBF process is a sophisticated evolution of standard LPBF. Here’s a simplified breakdown:

1. CAD Modeling with Material Zones

- Engineers design the part and assign specific regions to different materials.

- Generative design tools (like nTopology) help optimize performance-driven zones.

2. Selective Powder Deposition (SPD)

- Different powders are deposited in assigned regions using a patterned recoater.

- Precision is key to avoid cross-contamination.

3. Laser Fusion with Tailored Settings

- A high-power laser fuses each powder type with custom settings for melt efficiency.

- Parameters like power, scan speed, and hatch spacing vary by material.

4. Layer-by-Layer Fabrication

- The process repeats, layer by layer, until the full part is complete.

Common Tools Used:

- Software: nTopology, Siemens NX, Materialise.

- Hardware: Advanced LPBF systems like Aconity3D MIDI+ with multi-material recoaters.

Advantages of Multi-Material LPBF Technology

MM-LPBF delivers unparalleled design freedom and functional performance by allowing material placement based on need—not limitation.

Why It Matters:

- Consolidates complex assemblies into one part.

- Enables functional grading (e.g., wear-resistant exterior + ductile interior).

- Combines mechanical, electrical, and thermal characteristics.

- Drives innovation in cutting-edge industries.

Top Benefits:

- ✅ Lightweight yet strong components

- ✅ Customized regional performance

- ✅ Material and cost efficiency

- ✅ Freedom to design beyond traditional constraints

Key Challenges and Limitations

Like all emerging technologies, MM-LPBF faces several hurdles:

1. Material Compatibility

- Different metals have varying thermal behaviors.

- Mismatched expansion and cooling rates can cause stress and delamination.

2. Interfacial Defects

- Common defects include porosity, micro-cracks, and residual stress at material junctions.

- Advanced imaging (e.g., EBSD, Micro-CT) shows these issues often correlate with build direction.

3. Limited Design Standards

- Few established frameworks exist for designing multi-material parts.

- Engineers rely on FEA and iterative testing.

4. System Cost & Complexity

- MM-LPBF equipment is more costly and demands skilled operation.

- Calibration and quality assurance are critical.

Case in Point:

A study by Griffis et al. (2025) involving 904L stainless steel and bronze revealed that build orientation directly affects interfacial crack formation. When steel was printed over bronze in the Z-direction (SS, Br)z, cracks were significantly reduced due to more favorable thermal gradients and stress distributions.

Real-World Applications of MM-LPBF

MM-LPBF is being adopted across industries that demand performance-driven customization:

1. Biomedical Implants

- Graded stiffness to match bone elasticity.

- Porous structures promote osseointegration.

- Applications: Orthopedic implants, cranial plates, dental prosthetics.

2. Aerospace Components

- Lightweight and heat-resistant hybrid parts.

- Applications: Turbine blades, structural mounts, heat exchangers.

3. Energy Systems

- Multi-metal pathways for thermal management.

- Used in power electronics, heat exchangers, and battery housings.

4. Transportation & Tooling

- High-wear zones paired with flexible cores.

- Embedded electronics in functional tooling.

Mini Case Study:

Griffis et al. demonstrated a TPMS gyroid lattice printed in bronze and 904L stainless steel, which showed superior surface area, internal connectivity, and strength—ideal for load-bearing and biomedical applications.

Why Build Orientation Matters in MM-LPBF

Build orientation plays a critical role in the final part quality.

Key Influences:

- Crack Propagation: More likely along certain interfacial planes.

- Melt Pool Behavior: Affected by laser direction and gravity.

- Mechanical Performance: Properties like strength and fatigue vary with direction.

Backed by Research:

Research by Griffis et al. (2025) confirmed that build orientation governs interfacial defect formation. Their use of EBSD and EDS showed fewer cracks in the (SS, Br)z configuration, while Micro-CT scans highlighted that nano-scale cracking was a key factor in premature mechanical failure.

These findings underscore the importance of orienting materials strategically to minimize thermomechanical stress during printing.

The Future of Multi-Material Metal 3D Printing

MM-LPBF is evolving rapidly, with breakthroughs that could accelerate mainstream adoption:

1. In-Situ Monitoring & AI Optimization

- Real-time feedback loops improve quality.

- AI fine-tunes parameters during printing.

2. Regulatory and Industry Adoption

- Standards are emerging for medical and aerospace applications.

- Traceability and compliance will unlock broader use.

3. Material Database Expansion

- Development of validated material combinations will reduce trial-and-error.

4. Hybrid Manufacturing Integration

- Combining additive with CNC machining delivers precision and surface finish.

Conclusion: Putting It All Together

Multi-Material LPBF is transforming how we engineer metal parts—enabling hybrid components that are lighter, stronger, and smarter. By integrating multiple materials into a single design, MM-LPBF unlocks a level of functional complexity that traditional methods can’t match.

Despite challenges in interface integrity, process complexity, and material pairing, the future is promising. With advances in simulation, AI-driven monitoring, and material science, MM-LPBF is paving the way for innovation in biomedicine, aerospace, energy, and beyond.

Whether you’re a design engineer, researcher, or curious learner—now is the time to explore the possibilities of this cutting-edge technology.

Frequently Asked Questions (FAQ)

Can you mix any two metals in MM-LPBF?

Not always. Metals must have compatible melting points and thermal behavior. Popular pairings include steel/copper and titanium/tantalum.

What industries use multi-material 3D printing?

MM-LPBF is used in aerospace, biomedicine, energy, automotive, and defense.

How does MM-LPBF differ from welding or cladding?

Unlike welding, MM-LPBF offers micron-scale precision and enables the creation of internal structures and complex geometries that traditional methods cannot achieve.

Sources

- Griffis, J.C., Shahed, K., Meinert, K., Yilmaz, B., Lear, M., & Manogharan, G. (2025). Multi-material laser powder bed fusion: effects of build orientation on defects, material structure and mechanical properties. npj Advanced Manufacturing, 2, 5. https://doi.org/10.1038/s44334-025-00020-5