What If a Tiny Implant Could Power Itself and Help Your Bones Heal?

Picture this: a miniature implant that doesn’t just fill a gap in your bone—it actively helps it heal, using electricity it generates all by itself. No wires, no batteries, just smart science doing its job from inside your body. That’s not science fiction—it’s the future of bone repair. By combining cutting-edge 3D printing with materials that move and generate energy like living tissue, scientists are turning passive implants into active healing machines.

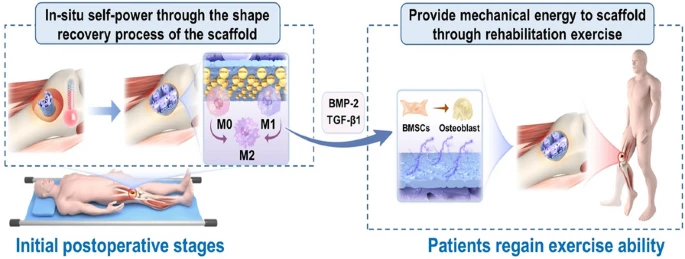

This next-gen scaffold isn’t just a placeholder—it’s a powerhouse. Engineered with shape-memory polymers that expand in response to body heat and piezoelectric nanofibers that convert motion into electric signals, the implant harnesses your own natural energy to accelerate bone repair. Whether you’re walking, stretching, or simply warming up, your body’s basic functions trigger a stream of regenerative signals right at the injury site. It’s medicine that moves with you—literally.

What the Study Found

In a major breakthrough published in the Journal of Nanobiotechnology (Li et al., 2025), scientists engineered a “smart” 3D-printed scaffold using two remarkable materials: shape-memory polyurethane (SMPU) and PVDF-TrFE piezoelectric nanofibers. Together, these materials created a scaffold that could reshape itself and generate electrical energy during deformation—both of which are crucial for bone healing.

The SMPU provides the flexibility to compress the scaffold during surgery and the strength to expand it once implanted. Meanwhile, the PVDF-TrFE nanofibers respond to movement or compression by producing electrical currents—no batteries or wires required. These tiny electrical pulses are biologically meaningful: they encourage bone cells to grow and promote anti-inflammatory immune responses.

Lab tests and animal studies proved this isn’t just theoretical. The scaffold generated up to 0.85 volts—enough to stimulate healing—and consistently improved bone regeneration compared to passive implants. It’s a self-powered, bioactive solution tailored for real-world healing.

Why It Matters

This innovation could completely change how we approach complex bone repairs. Here’s what makes it so impactful:

- Smaller Incisions, Smarter Healing: The shape-memory design means it can be inserted in a compact form through small openings. Once inside the body, it expands to fit the damaged area precisely—making surgeries less invasive and reducing recovery time.

- Built-In Biological Boost: The tiny electrical impulses generated by the scaffold mimic the body’s natural healing signals. These impulses activate immune responses and stimulate bone-forming cells—accelerating regeneration and enhancing the quality of repair.

- Low Effort, High Benefit: Patients don’t have to do anything extra. The scaffold responds automatically to natural movement or body heat. That means even those with limited mobility post-surgery can benefit from continuous, low-level healing stimulation—no batteries, no wires, no hassle.

- Clinically Relevant Design: The scaffold’s ability to generate healing signals without external power makes it ideal for patients in post-op recovery who can’t tolerate bulky or high-maintenance devices.

How They Did It

The magic behind this self-powered scaffold lies in its advanced material design and smart engineering.

- Shape-Memory Polymer (SMPU): This 3D-printable material is soft and moldable at lower temperatures, but when it reaches body temperature, it “remembers” and returns to its original shape. That makes it perfect for compact insertion during surgery and full expansion once in place, ensuring a tailored fit for the defect site.

- Piezoelectric Nanofibers (PVDF-TrFE): These are ultra-thin fibers that create electricity when mechanically stressed—like bending or stretching. Integrated into the scaffold, they turn motion and deformation into healing energy.

Using electrospinning and additive manufacturing, researchers blended the two materials into a unified scaffold structure. During physical activity or even subtle body movement, the scaffold deforms slightly—activating the piezoelectric fibers and generating micro-currents. These currents influence both bone-building cells (osteoblasts) and immune cells, creating a favorable healing environment without any external input.

Key Results

The study revealed powerful and promising results that highlight the effectiveness of the self-powered scaffold:

- Responsive Shape Recovery: Once inside the body, the scaffold reliably returns to its original shape with precision, filling the bone defect perfectly. This ensures a secure and supportive structure for bone regrowth.

- Consistent Electrical Stimulation: Whether during shape transformation or under ongoing movement, the scaffold generated stable electrical outputs—up to 0.85V. These micro-currents are key to activating bone-forming cells and fine-tuning the immune environment for optimal healing.

- Enhanced Healing in Vivo: Animal studies using rabbit tibia defects showed that scaffolds with electrical functionality led to significantly improved bone formation compared to traditional, non-electric implants. Healing was faster and more robust.

- Immune Modulation: The scaffold promoted a shift in immune response toward the M2 macrophage phenotype—a known promoter of tissue repair and anti-inflammation.

The Bigger Picture

This isn’t just a smarter scaffold—it’s a preview of the future of personalized, self-powered healing technologies. As research progresses, the broader implications are profound:

- Long-Term Biocompatibility: Scientists are now focused on ensuring that the scaffold remains safe and stable over time, gradually degrading without disrupting tissue or losing effectiveness. Early results show promising integration with natural bone remodeling.

- Human Clinical Trials: The next milestone is testing this innovation in real-world medical scenarios—where it could shorten recovery, reduce the need for repeat surgeries, and improve long-term outcomes for patients with complex fractures.

- Beyond Bones: The foundational technology—shape-memory materials plus piezoelectric fibers—can be adapted for other tissues like muscles, nerves, or even skin. That means this platform could power a new generation of smart implants across regenerative medicine.

- Energy-Free Implants: This breakthrough points to a future where implants don’t rely on batteries or external devices at all. Instead, they’ll harvest biomechanical energy from within the body—making treatment more efficient, less invasive, and far more sustainable.

Wrap-Up / Takeaway

This isn’t just a new way to patch a bone—it’s a leap into a smarter future of medicine. The 3D-printed shape-memory piezoelectric scaffold stands out because it works with the body, not just inside it. By turning heat and movement into healing energy, it rewrites what we expect from implants: no wires, no batteries, just natural motion turned into medicine.

The research doesn’t just show it’s possible—it proves it works. And with clinical trials on the horizon, we could soon see a shift in how bone injuries are treated worldwide. It’s the start of a new era where implants are active allies in recovery.

Original Research Reference:

Li, B., Ma, Y., Fatima, K., Zhou, X., Gu, X., Chen, S., & He, C. (2025). 3D printed shape-memory piezoelectric scaffolds with in-situ self-power properties for bone defect repair. Journal of Nanobiotechnology, 23, Article 244. https://doi.org/10.1186/s12951-025-03325-x

Ready to explore more about this revolutionary technology?

Subscribe to our newsletter for the latest updates on advanced medical implants and regenerative medicine breakthroughs, or contact us today to learn how you can be part of the future of bone tissue engineering!