Abstract

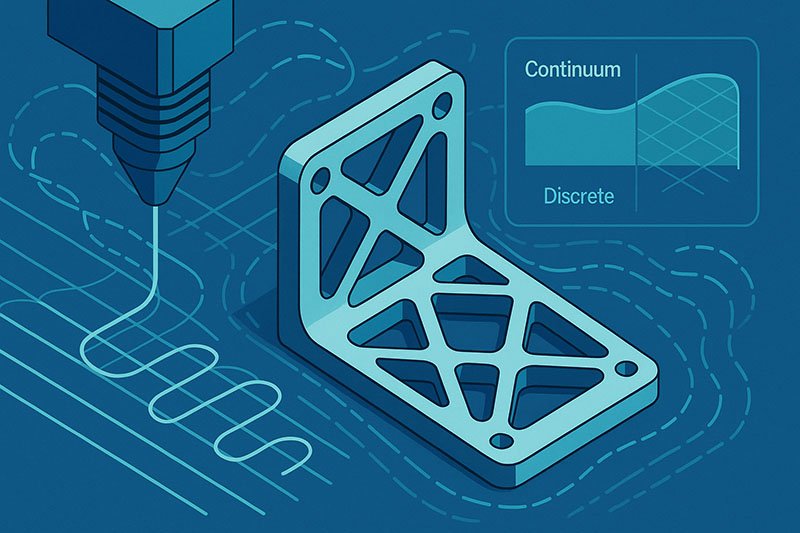

Reliability in material-extrusion additive manufacturing (AM) suffers from a mismatch between continuum-based designs and the discrete realities of printing—finite nozzle diameter, raster spacing, and weak interlayer bonds. A new technique integrates these printer limitations directly into topology optimization (TO), co-optimizing material layout and a realizable toolpath while modeling layer-bond mechanics. Experiments show markedly better alignment between predicted and measured properties—especially at low-to-medium relative densities—pointing to more predictable performance in aerospace, medical, and other safety-critical domains.

1) Introduction: From Elegant Designs to Reliable Prints

Problem: TO produces lightweight, high-performance forms, but printed parts often drift from the digital ideal due to over/under-deposition, stair-stepped curves, and anisotropy from imperfect interlayer bonds. These discrepancies inflate mass, reduce stiffness, and complicate qualification.

Contribution: A toolpath-aware approach that moves reliability upstream. It encodes nozzle diameter, raster spacing, and bond-region stiffness into the design problem so the “optimal” shape is one the printer can actually realize.

2) Why Extrusion-Based AM Struggles With Reliability

Discrete strands vs. continuum assumptions. Conventional TO treats the design domain as a continuous medium. In practice, the nozzle deposits lines of finite width; curves and thin features must be approximated by parallel rasters, creating gaps (under-deposition) or overlaps (over-deposition).

Interlayer bonding and anisotropy. Bond regions between strands/layers exhibit lower stiffness/strength than the bulk, producing direction-dependent properties. Defects (pores, incomplete fusion, warping) further erode performance. Early detection and process awareness improve yield.

Qualification burden in regulated sectors. In aerospace and medical contexts—where traceability and repeatability are non-negotiable—variability increases testing and slows adoption. Designing with manufacturing constraints from the outset helps shrink that gap.

3) Conventional Workflow vs. Printer-Aware Design

Traditional pipeline: (1) Optimize a continuum model → (2) export geometry → (3) slice → (4) print. Critical production decisions—line width, raster angle, path order—arrive after optimization, so mechanical predictions drift from the manufactured part.

Printer-aware shift: Integrate the toolpath and bond mechanics into the optimization itself, then output a direct, G-code-like toolpath aligned to the optimized material architecture. The result is a single, physics-consistent problem that collapses design and manufacturing decisions.

4) Method: Co-Optimizing Density and Toolpath

4.1 Problem formulation (manufacturability-constrained TO)

- Design variables: relative density field (material layout) and an explicit toolpath parameterization capturing strand width (nozzle diameter) and raster spacing.

- Physics: linear elastic response with bond-region constitutive properties distinct from bulk, calibrated via coupon tests.

- Objective/constraints: minimize compliance (maximize stiffness) for a given mass/volume fraction, while enforcing strand overlap/gap limits and curvature feasibility tied to the nozzle.

4.2 Bond-region modeling and calibration

Introduce an interlayer “bond material” (reduced stiffness) to capture anisotropy. Fit parameters from experiments (compression/tension on designed cellular coupons) so predictions reflect the actual printer–material system.

4.3 Direct toolpath generation

Unlike slice-after-design workflows, the optimizer emits a toolpath consistent with the optimal strand placement—reducing slicer-induced drift and improving geometric/mechanical fidelity to the simulation.

5) Results: Closing the Simulation–Print Gap

Testbed: 2-D cellular (porous) architectures at ~30–90% relative density.

Key outcomes vs. conventional TO:

- ≤ ~70% density: Toolpath-aware parts show much better agreement with predicted stiffness/mass. Conventional prints exhibit over-deposition and higher-than-intended mass from overlapping rasters.

- ≥ ~70% density: Differences narrow, but the integrated method still avoids unnecessary material accumulation.

- Bottom line: More predictable mechanical properties based on the actual print process, not an idealized continuum.

Industry perspective: Quantifying limitations lets teams “plan for them from the outset,” producing components “as strong as they need to be—no more, no less.”

6) Engineering Workflow: Applying the Method

1) Characterize your system

- Measure nozzle line width, stable raster spacing, feasible minimum curvature.

- Calibrate bond-region properties via coupon tests across raster angles/build orientations.

2) Run toolpath-aware optimization

- Define load cases, constraints, target mass fraction.

- Co-optimize density and toolpath respecting strand geometry and bond mechanics.

3) Export toolpath + verify

- Print calibration specimens; compare stiffness, mass, anisotropy ratios to predictions.

- Use inline/near-line NDT (2D X-ray or CT) to quantify pores, lack-of-fusion, and bond quality; iterate as needed.

4) Scale to product geometry

- Apply to critical components; document process parameters and bond-property sets for qualification.

7) Use Cases: Aerospace, Medical, and Large-Format Extrusion

- Aerospace: Weight-critical brackets, tooling, lattice stiffeners. Printer-aware layouts cut mass variability and de-risk margins—helpful for qualification.

- Medical: Patient-specific anatomical models and surgical guides demand geometry/property fidelity; aligning optimization with raster physics improves fit and stiffness predictability.

- Large-format extrusion: With large bead widths and steep thermal gradients, combine printer-aware design with AI-driven in-situ monitoring to maintain geometry and bonding at scale.

8) Complementary Reliability Levers

- In-situ defect detection: Pixel-level, learning-based systems flag layer anomalies and trigger on-the-fly parameter corrections—reducing scrap.

- Materials/process improvements: Porosity/warping mitigation (controlled cure profiles, dual-cure photopolymer systems) stabilizes properties and pairs well with the method.

- Sintering-aware optimization (other processes): Binder-jetting research shows the value of embedding post-process deformation physics into design—part of the broader shift to manufacturing-aware design across AM.

9) Practical DfAM Checklist (Extrusion AM)

- Orient for loads and rasters: Align principal stresses with bead directions; minimize unsupported overhangs and strand-direction kinks that cause gaps/overlaps.

- Respect wall-thickness limits: Keep thin features above 2–3× line width unless locally reinforced.

- Design lattices with bead physics in mind: Feature sizes should be commensurate with line width; avoid tiny radii that force zig-zag rasters.

- Plan metrology/NDT early: Define acceptance criteria tied to predicted properties (mass deviation %, stiffness error, porosity) and validate with X-ray/CT sampling plans.

10) Limitations and Open Questions

- From 2-D to 3-D: Current validation focuses on 2-D cellular architectures; fully 3-D, multiaxial cases and complex toolpaths are active work.

- Multi-material & variable nozzles: Mixed bead widths/materials raise complexity; optimization must handle discontinuities and tool changes.

- Certification & portability: Demonstrate repeatable performance across printers, materials, and sites to satisfy aerospace/medical qualification.

11) Conclusion

Printer-aware topology optimization closes the loop between what we design and what we print. By co-optimizing density and realizable toolpaths—and explicitly modeling interlayer bond mechanics—the method reduces property drift where conventional TO is most vulnerable (low–mid densities). Combined with in-situ QA and disciplined DfAM, it can shorten qualification cycles and unlock more reliable AM parts in regulated, performance-critical sectors.

References

- MIT News. “Technique makes complex 3D-printed parts more reliable.” (Sept 25, 2025).

https://news.mit.edu/2025/technique-makes-complex-3d-printed-parts-more-reliable-0925 - Kim-Tackowiak, H., et al. “Topology optimization of 3D-printed material architectures: Testing toolpath consideration in design,” Materials & Design (2025), DOI: 10.1016/j.matdes.2025.114700

- 3Printr / 3Druck coverage. (Sept 26, 2025). https://www.3printr.com/ (search article title)

- XRAY (GreyB). “Layer Defect Prevention in 3D Printing.” (Feb 6, 2025).

https://xray.greyb.com/technology-deep-dive/layer-defect-prevention-in-3d-printing/ - Dhakal, N., et al. “Impact of processing defects on microstructure and performance in material-extrusion AM,” Engineering Science and Technology, an International Journal (2023).

- 3D Printing Industry. “Sintering-aware topology optimization enhances binder-jetting accuracy.” (Jul 30, 2025). https://3dprintingindustry.com/