At the Wuhan University of Science and Technology, researchers are exploring mass customization. Peng Hong and Xia Xinqiao are using 3D printing to put a spin on manufacturing. Mass usually means large amounts made to look the same and customization refers to unique and small productions, putting them together could add contradictory phenomena. Most consumers hear “customized” and think that it will be expensive. However, they will continue to look for that shoe with the perfect fit, color, and functionality. Mass customization could save time and effort while also offering great profit for manufacturers. Realizing the potential for customization with 3D printing, the study explored martial arts shoes. Puma has been great at providing customization options. Back in 2010, they released the “Creative Factory” which allowed customers to customize shoes at the storefront.

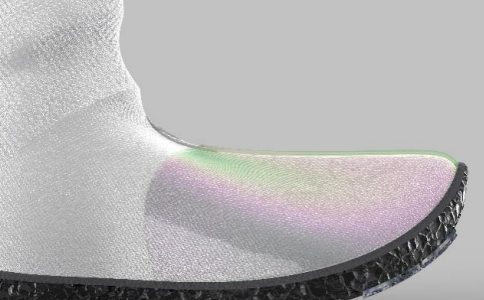

Martial arts shoes have to protect both the ankles and skin of the wearer, while also still being lightweight and flexible to accommodate the range of movement that is required. There will be challenges such as limited materials and molds, difficulties with large quantities, and problems with exchanges of products. To overcome some of the issues, it is suggested to use a small foot scanner that could be installed in stores to measure feet. The data could be then uploaded and made in a factory. This is another area where 3D printed shoes could be useful for footwear companies.

Original article: https://3dprint.com/245422/china-case-for-the-mass-customization-of-3d-printed-martial-arts-shoes/

#3DShoes #3DPrintedShoes #3DPrinted