Classical dance involves very specific techniques and movements, often associated with harmony and grace. Behind this idea, there is obviously a lot of work done by the dancers, efforts that of course can take a toll on the body itself. What instantly comes to mind of course are feet and specifically the balls, with dancers known for experiencing feelings of discomfort. This is one of the challenges being addressed by the young German startup act’ble: it has imagined custom-made ballet shoes – or pointe shoes – designed in part thanks to 3D printing. Indeed, the sole is manufactured layer by layer using TPU to bring more comfort and stability to the wearer as well as to reduce the environmental impact of the production process. We met with the team to learn more about this innovative product – it is certainly not everyday that you hear about the combination of ballet and 3D printing!

3DN: Could you introduce yourself and your connection to 3D printing?

a c t ‘ b l e is a young german company creating a new art of movement. Design and Research together with high level athletes leads to the development of a new pointe shoe with 3D-printed soles for classical ballet and contemporary. We want to enable dancers to make a difference in their performance, life and world. Due to advanced materials and their unique geometry, act’pointes outlast others in the market up to 5x longer than traditional pointe shoes.

Sophia Linder, the founder act’ble (photo credits: Jörg Donecker)

3DN: How did a c t ‘ b l e start?

Pointe shoes have been made for centuries in over a hundred traditional steps. Those shoes have a lifetime of one day in professional dance and represent an enormous health risk for the dancer. From a medical point of view an absolute torture method; from an environmental and economic point of view a disposable product. Our founder, Sophia Lindner, wanted to improve the life of ballet dancers by producing a completely new pointe shoe. The business idea was born in 2018 while Sophia Lindner was writing her bachelor thesis.

3DN: Can you tell us more about the manufacturing process of your pointe shoe?

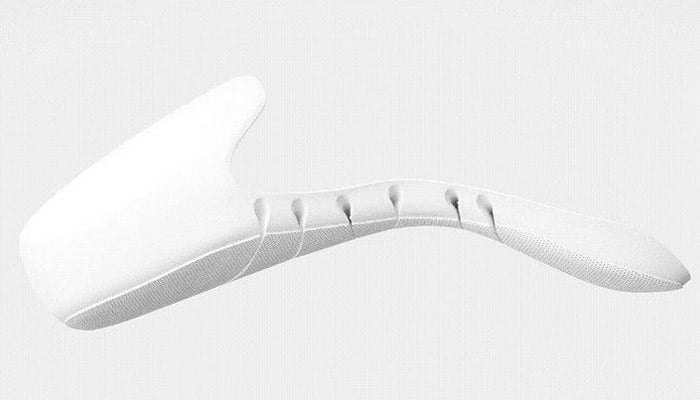

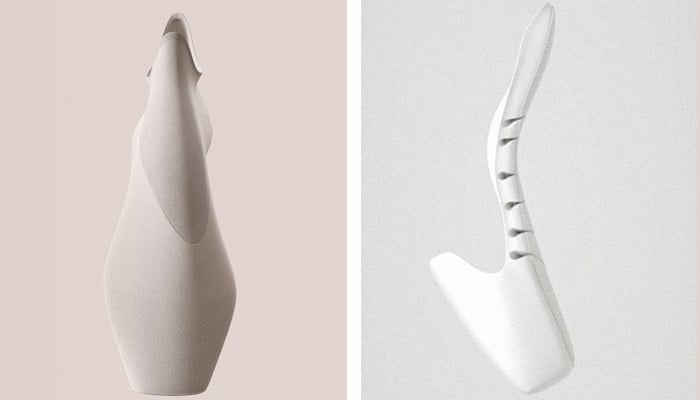

Our shoe is a modular and interchangeable concept: act’sole, act’skin, and act’laces. Each component allows for the change of worn out parts to new ones, as well as functional and aesthetic combinations. The heart of our shoe is the additively manufactured sole, which is made out of TPU. The act’skin is made up of a three-layer knit: merino wool, polyester, and grilon with various compression zones to distribute forces in a well-balanced form to the body composition

The act’laces are made to attach the act’pointes to the foot and to absorb the vertical forces on several parts of the foot, minimizing the occurrence of pressure points around the dancer’s feet.

The pointe shoes are tailor-made

3DN : And what about the sole more precisely?

To eliminate the conflict between the necessary flexibility and stability, our sole has cuts at the bottom. These cuts allow free movement for the upward and downward rolling movements of the foot, where physiological walking is not possible with traditional pointe shoes. On the other hand, for standing on the toes, the optimal support function is ensured by the segments closing and blocking. To achieve this special geometry, we are using a Laser-Sintering-Machine to 3D print our high quality soles. In 3D printing we have found a tool that offers the same precision and individuality as the athletes themselves.

3DN : What are the benefits and limitations of 3D printing for act’ble?

Through the TPU material and detailed geometry of the sole, which we can only achieve through 3D-printing, the act’soles are ready-to-wear without break-in and last significantly longer than traditional pointe shoes. If you have a wider or narrower foot, the sole is designed to automatically adjust to the width of your foot. The limits? The high production costs.

The 3D printed sole (photo credits: act’ble)

3DN: What feedback have dancers given you?

Our constantly improving prototypes were frequently tested by professional dancers as we always wanted to include their feedback. The dancers who already wore our finished product do really love the feeling of dancing in act’pointes as they feel so much less pain. They also appreciate the support and the flexibility the shoe offers

3DN: What are act’ble’s future projects?

As our soles are additively manufactured, in the future it will be possible to produce identical customized soles for your act’pointes in the shortest possible time and that is fitted perfectly to your individual feet shape. This opens up possibilities that were previously unheard of in this industry.

Photo Credits: Act’ble

3DN: Any last words for our readers?

If you are a ballet dancer, visit our homepage or follow us on instagram to find out more about our pointe shoes.

What do you think of the startup act’ble? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

SOURCE: https://www.3dnatives.com/en/3dstartup-actble-3d-printed-dance-shoes-050420224/#!