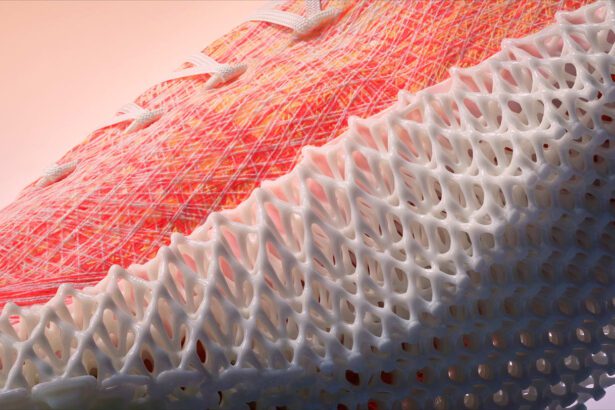

Footwear brand Camper is recognized for stylish yet casual and comfy shoes. They have recently found that they can benefit from 3D printing technologies and have installed a number of 3D printers from BCN3D Technologies. The design team works on a fairly tight schedule, with each concept and shoe design needing to be completed within three months. Before obtaining 3D print at its, Camper had relied on external prototyping to produce designs. This process takes a couple of weeks per shoe iteration, so design changes were limited. Since Camper installed Sigma and Sigmax 3D printers they have drastically sped up iteration times for shoe designs. Prototypes can be turned out in house in as quickly as 24 hours which helps Camper designers and engineers explore various new designs.

By using 3D printing it allowed footwear companies to design models in a shorter timeframe and at much lower costs. In return, this gives designers more time to come up with new and creative design concepts while ensuring function and comfort. Camper chose BCN3D’s printers because of their dual extrusion capabilities and their precision. This allows them to use water-soluble print material, which means they can work with more geometric shapes and reduces design time for the whole collection. It will be amazing to see what this Spanish footwear brand will bring us in the future.

Original Article: https://www.3dprintingmedia.network/3d-printing-camper-shoe-design/

#3DShoes #3DPrintedShoes #3DPrinted