Steadily, Stratasys (NASDAQ: SSYS) has been releasing industry-specific versions of its PolyJet technology: one targeted at dental, one at medical, another for engineering, and so on. Now, it’s taking on the fashion world with the Stratasys J850 TechStyle 3D printer, a PolyJet machine specifically for 3D printing textiles, clothing, accessories, and footwear. The move is an interesting one that makes the 3D printing stalwart one of the few in the additive manufacturing (AM) sector with a specific focus on fashion.

The J850 TechStyle relies on Stratasys’s unique inkjet technology, capable of 3D printing more than 600,000 distinct colors via Agilus30 CMY ink, as well as multiple shore values. Unlike previous PolyJet machines, this one is designed specifically for 3D printing onto fabric using VeroVivid resin and Vero ContactFlex, a transparent coating meant to provide a soft and smooth feel. The J850 TechStyle can print onto a variety of materials, such as denim, cotton, polyester, linen, and leather at volumes ranging from single pieces to tens of thousands.

SSYS 2Y22 Design by Ganit Goldstein. Image courtesy of Stratasys.

Fashion expert Lidewij Edelkoort said of the technology, “From decorative craft to creative engineering comes this hybrid machine from Stratasys, as an answer to a million prayers, allowing the ascension of embellishment for an inclusive following.”

While there have been experiments in fashion 3D printing in the past, most have remained at the experimental level. We can exclude jewelry, which has long taken advantage of both direct and indirect methods of AM for production, as well as footwear. So, though Dita von Teese has been adorned in unique 3D printed looks and Nervous System performs boutique work, it has been difficult for the technology to find a footing in garment making on a larger scale. 3D Systems attempted to launch a textile line before its entire consumer division was scrapped. This is in large part due to the tough nature of polymers, which result in chunkier elements that lend themselves more to accessories than fabrics.

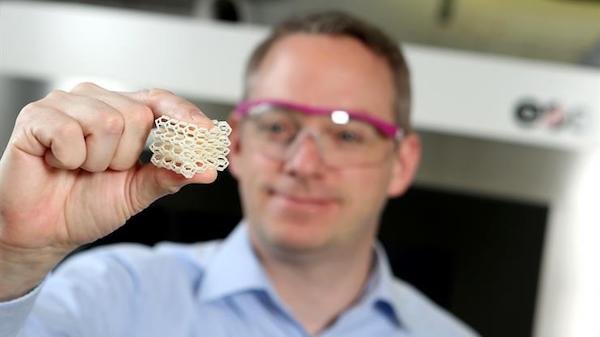

The J850 TechStyle 3D printer. Image courtesy of Stratasys.

It was primarily Stratasys Art, Design and Fashion Director Naomi Kaempfer who has pioneered this path for the company. Working with artists and designers like Neri Oxman, Zaha Hadid, and Daniel Widrig, Kaempfer has seen PolyJet applied to some truly remarkable pieces of art and fashion. This led to such accomplishments as dressing Bjork for a tour and having work acquired by the San Francisco Museum of Modern Art. Over nearly the past decade, the technology has been refined and tweaked to the point where it could move from beautiful, yet bulky objects to true textiles.

“As far back as 2019, I predicted that in just a couple years we would see 3D printing incorporated into high-end fashion houses,” said Stratasys Art, Design and Fashion Director Naomi Kaempfer. “That time is here. We learned and modified those early designs, and created a new, dedicated printer using 3DFashion technology that is allowing fashion designers to create without limits. This is just the beginning of the journey as we continue to evolve this technology and pioneer new fashion design innovations.”

Now, the company is commercializing the ability to 3D print directly onto fabric, which enables digital automation and limited-edition clothing with a shorter time-to-market. To further the reach of the technology, Stratasys is working with Dyloan and the D-House in Milan. The company describes D-House as a “top innovation center of excellence for evolving fashion technology.”

SSYS 2Y22 Design by Jasna Rokegem and Travis Fitc. Image courtesy of Stratasys.

Stratasys will showcase its 3DFashion in its upcoming SSYS 2Y22 collection at Milan Design Week from June 6 -12, 2022. Meant to demonstrate the impact of the COVID-19 pandemic on fashion and design, the show will include high-end dresses and suits, daywear, handbags, accessories, and shoes, as well as lighting and luxury packaging from seven design teams.

SSYS 2Y22 Design by Karim Rashid. Image courtesy of Stratasys.

The only other additive company truly tackling the typically soft and flowing niche that is clothing, is Kornit Digital. 3DPrint.com Senior Editor Sarah Saunders documented some of Kornit’s work in the space, which is powered by a technology capable of inkjetting “digital embroidery” onto textiles. Kornit also acquired Voxel8, which developed a process for 3D printing shoe uppers and other, tougher fashion pieces.

As both companies strive to tackle the emerging world of digital fashion, it will be interesting how products like the J850 TechStyle compete with or complement existing clothing manufacturing technology. For instance, there are automated embroidery and sequins machines. Direct-to-garment and sublimation technology also already exist and are used to dye and print onto fabric. In fact, they rely on similar inkjet, UV curing technologies.

Image courtesy of Stratasys.

This is why Kornit, traditionally a garment company, is entering the 3D space, as is Mimaki, a manufacturer of inkjet printers, including those for sublimation. So, what we may seeing here is Stratasys expanding beyond industrial 3D printing into fashion the way it is seeing increased competition from the 2D spaces. Benefits that PolyJet may bring is the ability to control the opacity and shore hardness of a textile. Additionally, if the company’s GrabCAD Print software is able to model clothing in 3D to show how it lays on a person, it may open up some interesting visualization possibilities to the fashion world, typically stuck in 2D modeling.

SOURCE: https://3dprint.com/290932/fashion-3d-printing-targeted-by-stratasys-with-new-textile-3d-printer/