In an era defined by a constant demand for fast fashion and ever-changing style trends, a look behind the scenes of the fashion industry reveals a less glamorous reality: a staggering 92 million tons of textile waste is created each year, not counting factory emissions and other byproducts of manufacturing processes. This cycle of consumption is fueled by a practice known as planned obsolescence, in which products are designed to deteriorate quickly, prompting consumers to replace them more often to generate consistent sales for large brands. Amid this backdrop of clothing with an expiration date, a shift in design practices is a must.

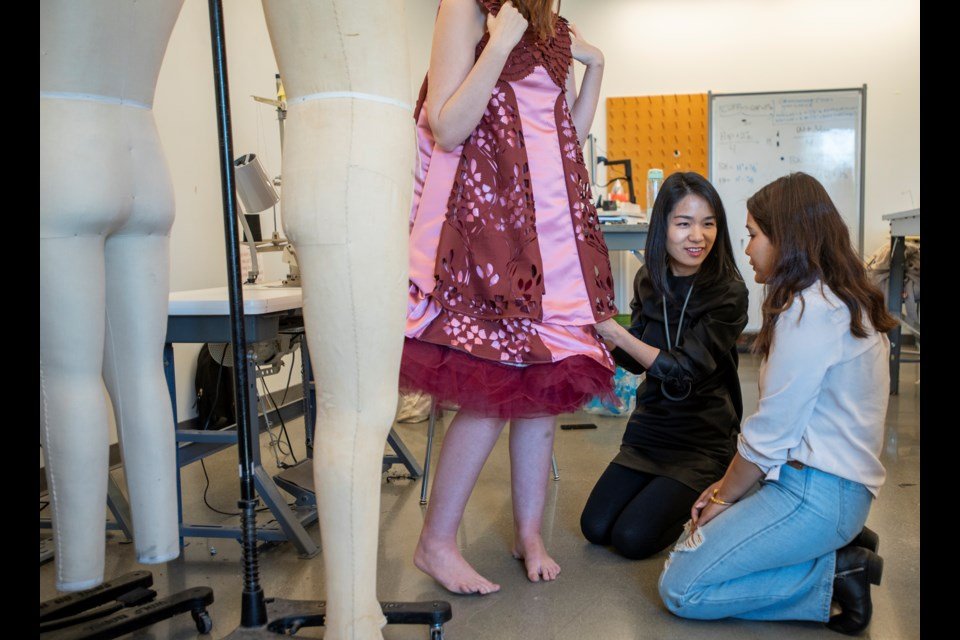

Photo: The University of North Texas

Enter Chanjuan Chen, an associate professor at the University of North Texas who is threading a new narrative in fashion stitched with sustainability. Professor Chen’s innovative approaches include the use of 3D printers, which lay the blueprint for several of her designs. This isn’t the only hat she wears: she also serves as the graduate coordinator for the university’s Fashion Design Master of Fine Arts Program, a cornerstone for emerging designers that is recognized for the award-winning creations of its students.

Professor and Department of Design Chair Hepi Wachter, Ph.D., illuminates the department’s commitment to mindfulness and sustainability.

“We have outstanding facilities, from well-equipped fashion design studios to the Digital FabLab, accommodating students to hone their technical garment-making and technology skills,” Professor Wachter says. “The design professions have always spearheaded sustainability in the arts.”

Photo: The University of North Texas

Chen’s journey toward sustainable design began in China, where she completed her undergraduate degree with the vision of making her mark on the runway. However, her internships, which included visits to various fashion factories, pulled back the curtain on the less inviting side of the industry. Confronted with strenuous working conditions for employees and an excess of material waste, she carried these experiences with her to the United States, where she pursued her master’s degree at UNT.

“I was able to explore the whole entire life cycle of garments and how they were made,” Chen says. “Then, I had an understanding of being exposed to the idea of sustainable fashion. At that time, sustainable fashion was not that common.”

Years of research into various techniques, materials, accessibility considerations and style trends landed her on the path to teaching at Kent State University in Ohio before returning to UNT. Her findings led her to the emergence of 3D printing, and she began cultivating a plan around incorporating it into her work. Chen underscores the often-overlooked environmental cost of sourcing more common materials: even cotton, a fundamental fashion staple, requires excess water, chemicals and transportation to various factories before it’s ready for the consumer. In addition to the low-quality materials that are standard in the market and the need for more durable options, Chen pushes her students to consider rapidly changing trends and the fact that most people discard their clothes before they even have time to wear out.

“In the past five years, I’ve just tried different ways, from zero waste, which means when you cut your pattern, you don’t waste any scraps, to upcycling, where you use secondhand materials or turn your old shirts into a new dress,” Chen says.

This exploration of sustainable practices led Chen to the concept of transformable fashion and, subsequently, to a subcategory known as modular fashion. Picture a reversible jacket or an IKEA couch that can be rearranged in multiple ways. But Chen’s interpretation of modular fashion goes beyond versatility — her 3D printing method enables consumers to continuously personalize their clothes. In lieu of the traditional path of hitting the fabric store and delving into a YouTube DIY rabbit hole, she envisioned a different route for wearers. Chen’s innovative creations can be linked together at various connecting points, allowing the owner to rearrange a single pattern into things like dresses, blouses or even skirts as often as they’d prefer without producing scraps or buying new pieces.

However, Chen’s path was fraught with a variety of hurdles in designing patterns for a 3D printer. One crucial piece of the puzzle was finding a material that could mimic the soft touch of typical garments while also being compatible with the printers. She found that thermoplastic polyurethane had the ability to become soft when expanded. It works well with her interlocking patterns and behaves similarly to typical clothing textiles, despite being plastic. Because it can be reused, it is also significantly less wasteful than regular plastics, which are often single-use.

Another roadblock to contend with is developing patterns that can be printed in pieces by smaller 3D printers, which are more accessible to the public due to their lower price point. Yet, for all of the hurdles she encounters, her rich background has given her the ability to triumph in each scenario. With 3D printing, the need to rely on external entities, such as overseas manufacturers, is significantly reduced. Instead of spending time on fixing communication barriers, designers can focus on their vision.

Chen’s work, which often carries strong societal messages, has garnered numerous accolades over the years. One particularly notable design, titled “United in Love,” is a piece that won the Vince Quevedo Best of Show Award at the International Textile and Apparel Association’s national conference in 2020. Her passion for wearable art is evident in this creation, which utilizes silhouettes of people holding hands to symbolize unity in adversity. The striking shade of blue represents peace, while the skirt she paired it with has an array of shapes and colors to demonstrate the rainbow of cultures throughout the world. Conceived during the height of the pandemic, it conveys a potent message about standing strong as one in the face of global challenges.

“This is an example of how I incorporate symbols and messages to try to bring awareness to social and cultural issues and, at the same time, promote sustainability,” Chen says. “So [I’m] not just talking about protecting the environment but also thinking about other political or economic issues around the world.”

Students at UNT are inspired by their professor’s vision and are keen to embrace this sustainable shift. “Most recently, I have opted to begin creating digitally as opposed to physically,” says Christian Thornton, a fashion design program senior. “In both art and design practices, preliminary creations are almost mandatory to achieve desirable results, and those preliminary steps produce preliminary waste.”

On the question of how the average consumer, or an aspiring fashion student, can contribute to sustainability, Chen advises everyone not to be daunted. Starting small, like cutting down dryer time or shopping secondhand, can make a difference. She believes that tiny, everyday habits can snowball into creative solutions for consistent change. For her students, she advocates reusing materials they already have. Instead of buying new fabric for a denim outfit, she nudges them to repurpose old denim pants from their closet.

“Not everybody chooses sustainability when designing because it requires more resources and more thought,” says Cindy Gonzalez Canjura, a fashion design program senior. “However, sustainability is the future of fashion and design, whether we like it or not. Our world is not going to wait for us, so we need to be part of the solution and not the problem.”

Chen is enthusiastic about the future of Texan fashion design. Each year, UNT students get the chance to dive headfirst into renowned contests like the Fashion Group International’s competitions, rubbing elbows with seasoned professionals while vying for coveted scholarship prizes. With an array of up-and-coming fashion brands and a growing influx of big-name retailers setting up offices in Texas, Chen believes the Lone Star State is primed to rival fashion meccas like New York City. So, keep your style radar tuned in, because Dallas is striding onto the list of the world’s most fashionable — and hopefully sustainable — cities.

by Melissa Breccia

Source: https://www.localprofile.com/arts-culture/the-rise-of-3d-printable-fashion-8057896