3D printing not only saves production time but it also helps with the cost. A German shoe company, Oberle – Gesunde Schuhe has turned to 3D printed shoes in an attempt to keep up with modern shoe companies. They want to better create specialty “healthy shoes” to provide to future customers. The company has been specializing in this area since 2006 and developed a recognized leadership in orthopedic footwear technology. Using their in-house X350pro 3D printer the company is getting an advantage over some of their competition.

3D printed footwear is really making an impression on the industry, and footwear applications are widely adopting additive manufacturing (3D printing) into production methods. The biggest benefit that can be seen is the personalization the technology can offer to consumers. Oberle – Gesunde Schuhe is focused on helping customers stay on their feet with a perfect fit. They use posture analysis to measure the way an individual holds their body and walking analysis to measure movement. The company has actually been including 3D technologies for a while now to ensure customization solutions. Like 3Dshoes.com, Oberle – Gesunde Schuhe understands the importance of this area.

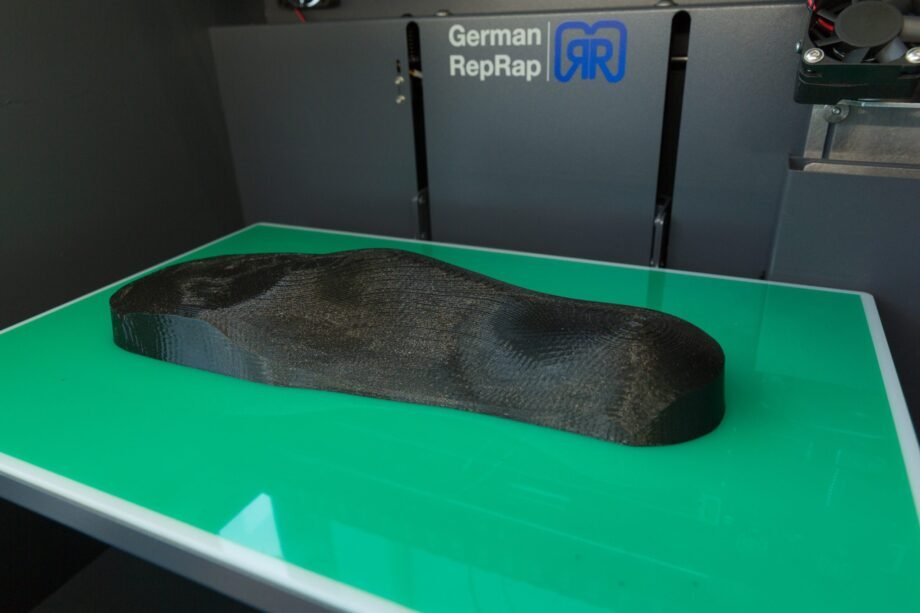

With 3D printing, they can easily create the shoe last. This is an integral product in the creation of a shoe. The last is shaped like a human foot and allows for the right shape to be created. Using the X350pro 3D printer the shoe lasts can be more customized to fit specific customer needs. The company utilizes a PET-G filament in the creation of the shoe lasts. They chose this filament because it has odorless printing and is capable of high print speeds. The material also has high strength and low risk of warpage. The X350pro works longer hours than employees and can run through the night on print jobs.

Original Article: https://3dprint.com/182190/german-reprap-oberle-shoes/

#3DShoes #3DPrintedShoes #3DPrinted