In the jewelry industry, additive manufacturing has already proven itself time and again. For example, take the case of the Indian 3D printing service Imaginarium who created a ring with 7,801 diamonds using 3D printing. A record at the time. After such a project, it is legitimate to ask how 3D technologies can change the way we design and produce jewelry. Not to mention, consider the various benefits and limitations of this manufacturing method in the sector. To find out more, 3Dnatives met with Roman designer Maria Clelia Scuteri, founder of the company Invaerso. In 2020, the company was awarded the “Worth Partnership Project”, an EU-funded program to support the European creative industry in creating partnerships in the field of design and innovation.

3DN: Could you introduce yourself and Invaerso?

3DN: Could you introduce yourself and Invaerso?

3DN: Could you introduce yourself and Invaerso?

3DN: Could you introduce yourself and Invaerso?Hello, my name is Maria Clelia Scuteri and I am an architect and product designer in Rome. Invaerso was born in 2020, but it is the result of years and years of research, tests and prototypes made in the previous years (the idea came to me in 2013, the year I graduated as an architect). I accumulated know-how and experience and gradually became passionate about product design. I find it fascinating to be able to think and design a product, produce it, test it, recalibrate it until it is perfect, all in a short time. Having immediate feedback is very exciting for me.

3DN: Why did you choose 3D printing? How do you use it at Invaerso?

I discovered 3D printing a few years ago, and being a fan of innovation, production and research. Also, once I learned about it, I never gave it up. It’s a real revolution!

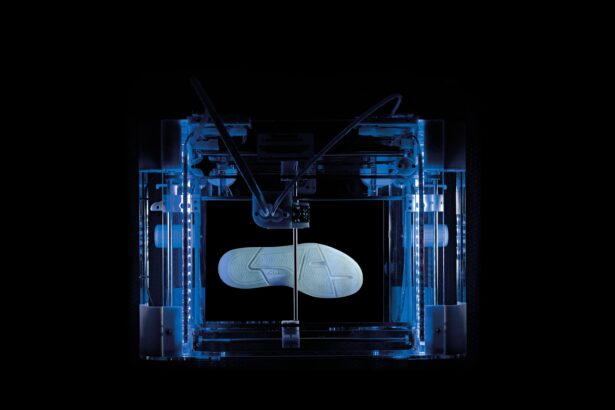

I have to say that I don’t just work with 3D printing, but combine it with different production techniques. I use it for rapid prototyping (for which any resin will do, even cheap ones), to test if a product works or needs to be modified, but also to cast final prototypes (as in the case of casting wax). Not only that, but I also sometimes cast metal directly. In short, there are endless possibilities! The production process is optimized according to the result to be obtained, as well as the level of complexity and detail.

Photo Credits: Invaerso

3DN: What role does innovation play in your field?

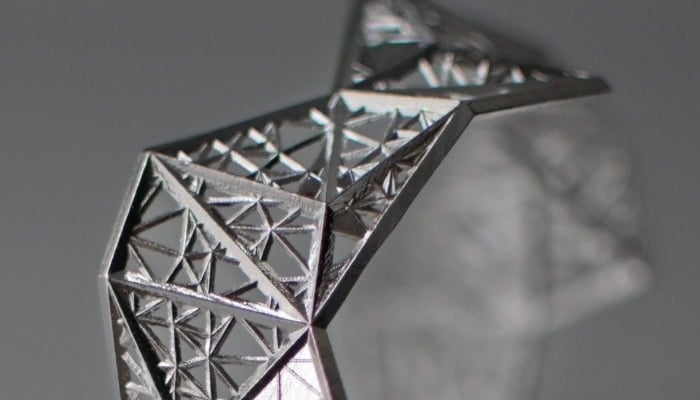

To innovate is to be able to experiment, in order to optimize a production process and/or the final result of the process itself. Personally, 3D printing in the world of jewelry allows me to create jewelry faithful to the geometries I design, that is to say pure and almost abstract.

Photo Creidts: Invaerso

3DN: In your opinion, what are the advantages and limitations of 3D printing in this sector?

The advantages are numerous, such as the ability to create extremely complex, refined and detailed shapes. The final result is also precise and rigorous in terms of geometry. Prototypes for testing are made quickly, with any kind of resin. Finally, no waste is produced.

I don’t see limits but only opportunities with 3D printing. That being said, we should never forget the value of handwork and craftsmanship. They are two very different things. We need technology to look to the future and at the same time we must also respect traditional knowledge.

Photo Credits: Invaerso

3DN: What challenges do you face in your work? Do you have any future projects in mind at Invaerso?

One of the biggest challenges is certainly to reconcile the different elements of the production chain. Behind each object is a different process. Each product tells its own story, a unique story I would say! Any plans for the future? To continue to amaze, to research and to innovate without ever forgetting the aesthetic component.

3DN: Any last words for our readers?

The best is yet to come! You can find the Invaerso website and store HERE.

What do you think about the use of 3D printing in the jewelry industry and the company Invaerso?

SOURCE:https://www.3dnatives.com/en/invaerso-on-rethinking-jewelry-with-3d-printing-190420234/