Overview

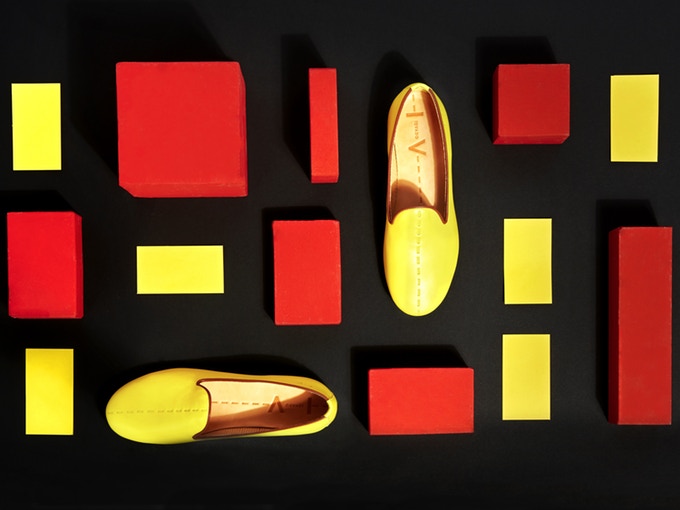

iovado represents a revolution in the custom hand-crafted production for the fashion industry starting with a timeless shoe.

iovado shoe is an ultra-luxury mocassino shoe, handcrafted in Italy, created to fit the exact shape of your foot, using biometric scanning and 3D technology for 240€.

iovado shoes are manufactured locally by the same hands that create top brand luxury shoes and combine Italian craftsmanship tradition with technology for a new level of comfort that we call “personal comfort“.

The result is a special shoe that fits like a glove, enveloped in finest soft calf leather.

Male Mocassino Shoe

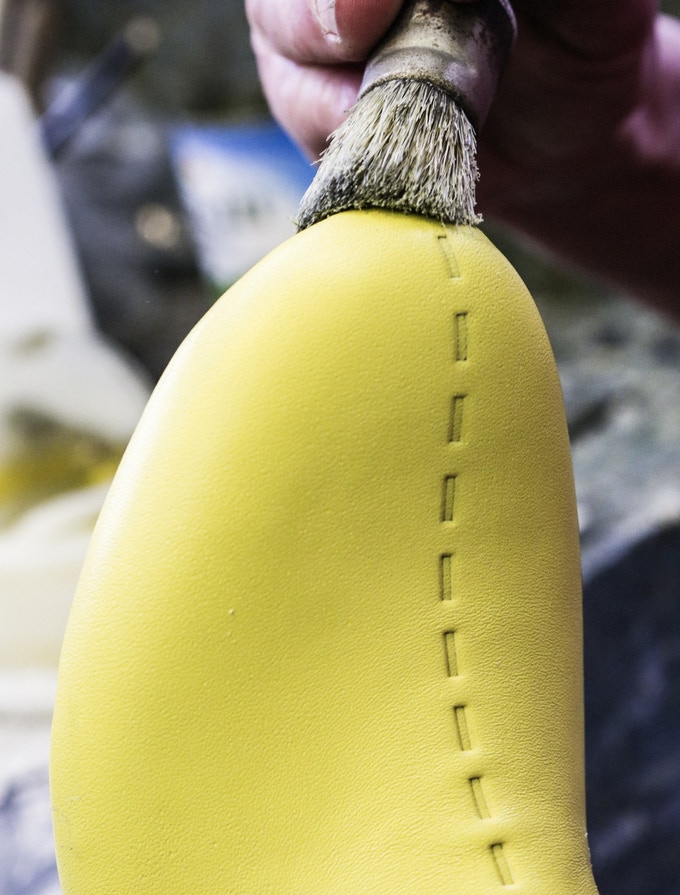

- “Sacchetto bolognese” construction method for a glove-like fit

- Premium calf leather with a specific thickness

- Leather outsole brushed vintage and hand-polished

- Cushioned Leather insole

- 1.5 cm / 0.6 inch heel

- Handcrafted in Italy

- Dotted line branded

Female Mocassino Shoe

- “Sacchetto bolognese” construction method for a glove-like fit

- Premium calf leather with a specific thickness

- Leather outsole brushed vintage and hand-polished

- Cushioned Leather insole

- 1.5 cm / 0.6 inch heel

- Handcrafted in Italy

- Dotted line branded

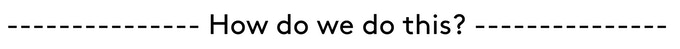

We use your mobile as biometric scanner and 3D printing technologies.

- The biometric scan allows us to get an accurate 3D model of your foot, wherever you are in just 10 minutes.

- The 3D printing technology allows us to reduce costs and production time so we can pass these savings to you.

Why would you buy something that doesn’t perfectly fit your feet?

As seen on:

You will be able to choose the add-ons at the end of the campaign, when we will send out the survey.

1) Download the app

First you need to download the iOS or Android app on your mobile. We will send you the link to download the app at the end of the campagin. If you don’t have a mobile (you can always ask a friend!) or don’t want to experience the “personal comfort” you will still be able to choose your standard size.

2) Print the reference sheet (two A4 papers placed side by side or one A3 paper) that we will send you via email at the end of the campaign.

3) Take at least 15 pictures of each foot individually.

4) Choose your color!

After the campaign, we will send you an email to let you choose your favorite color from the following:

Any irregularities are natural attributes of the leather and should be considered as characteristics of the product.

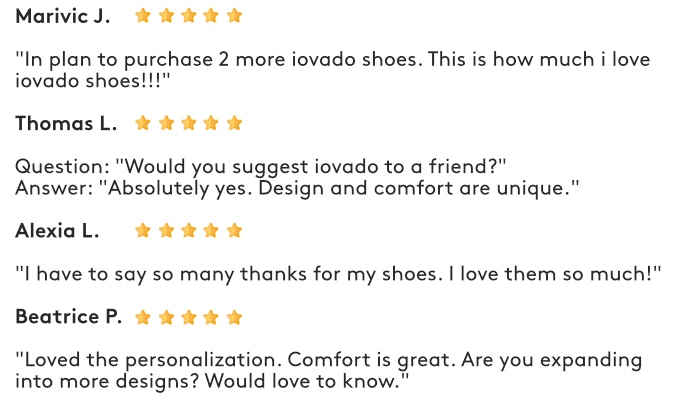

Over the last year we have been testing with hundreds of people, we have received a ton of great feedback, listened to our customers and made multiple improvements since then!

Recent advances in biometric scanning and 3D printing technologies make this the perfect time for our innovation.

We need your help to make it real. Hit one of the below buttons and show iovado to your friends.

iovado embraces cost transparency so that our customers limpidly know what they are paying for and can make purchases in full awareness.

By being online only, iovado eliminates brick-and-mortar expenses and passes these savings on to customers.

Everything we do we believe in the importance of a high degree of manual skills in the production of high-quality goods; we believe more attention should be given to the artisans who are the backbone of iovado’s quality. The way we give more attention to the artisans is by being transparent and revealing our costs.

Once the last gets in the hands of the Italian craftsmen…

We use “sacchetto bolognese construction” method which is rooted in Italian tradition and allows each shoe to fit like a glove.

What characterizes iovado shoe is the quality of the leather. We use premium calf leather, selecting only first choice with a specific thickness:

each pair of iovado Mocassino shoes is crafted, dyed, and burnished by hand.

The soles express Italian exclusivity: each sole is brushed vintage and hand-polished; therefore each sole differs from one another.

iovado shoes are handmade and packaged at the craftsmen’s workshops in Italy in the Marche region paying utmost attention to quality and design.

Each pair goes through a rigorous inspection to ensure that every shoe is of the highest quality.

iovado has been conceived from the idea of two Italian brothers Albert and Hans Paul to create an unique and timeless moccasin shoe with strong lines and very comfortable. The quality of our shoes is centred around three pillars: design, comfort and custom made.

The young entrepreneurs were born in Valdagno in the cradle of Marzotto a famous Italian textile industry; therefore, the bond with the fashion industry was inevitable.

Our vision is to bring breakthrough technologies to the traditional high fashion industry to make luxury goods affordable to everyone.

It all started 3 years ago, we were studying and working abroad and as fashion-minded people we were disappointed of seeing the same premium luxury shoe brands everywhere.

So we came back to Italy with a draw and an idea.

As former MSc students of Innovation and Technology at Bocconi University in Milan, we had the idea of using Biometric scanning and 3D printing technologies to create a unique, custom-made shoe.

We built several prototypes, we researched into the craftsmanship of shoes, talked to several artisans, exchanging ideas, getting feedbacks, breaking old bias and getting lost through the beautiful Italy.

We invested a lot of time talking to our beta users and improving our product. A lot of ups and downs, learnings and iterations.

And we are here now to introduce iovado to the world.

iovado loafer is a must-have, timeless shoe that fits several styles. Whether for the office, a business dinner, a party, or simply a casual weekend look. Plain and simple, available in a wide array of colors: from the classic brown leather to the light-blue Santorini, we have stylish colors that suit several occasions.

iovado shoes are characterized by dotted lines that represent the path made of steps into the future.

The dotted lines express action, progress and your next step.

We believe that action beats inaction. iovado shoe was born to embrace this concept while giving personality to who wears it.

Feel empowered to take new steps and let the dotted lines give you balance and drive for your next decisions.

We are the result of the steps we took in the past, and of the decisions that we take everyday. iovado shoes are all about inspiration. Let the dotted line find that inspiration in you, whilst empowering your next steps.

SUPPORT THEIR CAMPAIGN: https://www.indiegogo.com/projects/first-3d-scanned-luxury-italian-handcrafted-shoe#/