LaLaLand Production & Design, the largest shoe manufacturer in California, has announced an exciting new partnership with Elastium, a cutting-edge 3D-printing startup. Together, they aim to redefine the footwear industry with their innovative Hybrid model that combines 3D-printing technology and traditional manufacturing techniques. This collaboration promises to accelerate the shift towards localized, sustainable shoe production, offering brands a faster, more scalable, and cost-efficient way to bring their designs to market.

Their first product, the Orca sneaker by ELSTM, will debut this week from LaLaLand’s Los Angeles factory, marking the beginning of a new era for footwear design and production.

Addressing Industry Pain Points

The footwear industry is no stranger to challenges. Complex supply chains, high initial costs, and the ongoing impact of geopolitical uncertainties have long burdened shoe manufacturers. These issues have intensified demand for more localized production, reducing dependence on overseas suppliers and large-scale manufacturing facilities.

The LaLaLand-Elastium partnership addresses these challenges head-on with a solution designed for agility and efficiency. By blending the speed and customization capabilities of 3D printing with the mass-production potential of traditional shoe-making techniques, their new Hybrid model provides a flexible solution for brands of all sizes.

Perhaps the most significant innovation is their No-Minimum-and-Maximum-Order-Quantity (No-MMOQ) approach. Brands can now launch new designs with orders as small as one pair, eliminating the need for massive upfront production runs. This game-changing flexibility allows companies to test the market with minimal financial risk, all while maintaining the same high quality and craftsmanship.

Revolutionizing Footwear with Disruptive Technology

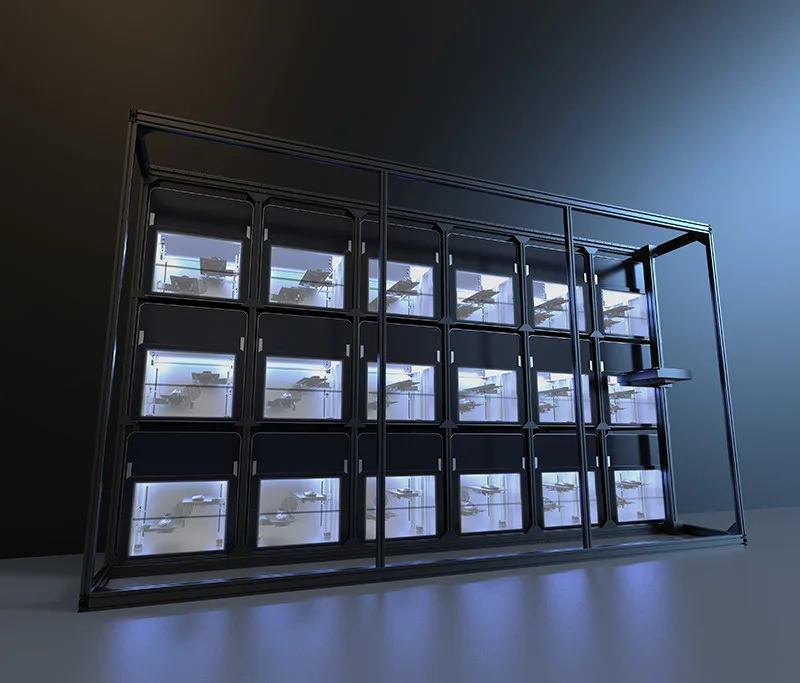

At the core of this new production model is Elastium’s proprietary FIDEM technology. This breakthrough integrates the world of 3D printing with traditional molding processes, allowing the seamless production of footwear that combines cutting-edge design with the proven reliability of traditional manufacturing.

Elastium’s 3D-printed foam, a key material in this process, is already turning heads in the industry. With an energy return rate of over 75%, it rivals the widely used EVA foam found in many athletic shoes. This high-performance foam not only provides excellent comfort and support but also underscores the sustainable potential of 3D printing in the footwear space.

Unlike traditional production methods, which often require costly molds and months of development, Elastium’s technology enables the creation of fully customized shoe components in just weeks. This speed, combined with LaLaLand’s established manufacturing infrastructure, ensures that the Hybrid model can meet the demands of today’s fast-paced fashion market.

The Orca Sneaker: A Symbol of the Future

The debut product of this collaboration, the Orca sneaker by ELSTM, embodies the potential of the Hybrid model. Set to launch this week, the Orca represents a perfect blend of design, performance, and sustainability. Made from Elastium’s 3D-printed foam and utilizing LaLaLand’s expertise in shoe manufacturing, the Orca showcases what’s possible when two innovative forces come together.

With sleek aesthetics and high-performance materials, the Orca is expected to capture the attention of athletes and casual wearers alike. Its minimalist design belies the complex technology beneath the surface, where FIDEM-enabled components provide superior comfort and durability.

Faster, More Sustainable, and Cost-Effective

One of the standout features of this collaboration is its potential to dramatically reduce the time and cost of bringing a new shoe design to market. Traditional production processes can take months and involve significant upfront investment. In contrast, the LaLaLand-Elastium Hybrid model allows brands to go from concept to store shelves in just weeks, cutting initial costs by up to 80%.

This efficiency extends beyond just speed and cost. By localizing production in LaLaLand’s Los Angeles factory, the partnership helps reduce the carbon footprint typically associated with overseas manufacturing and shipping. Moreover, the use of 3D printing allows for precise material usage, minimizing waste and contributing to a more sustainable production model.

Meeting the Growing Demand for Localized Production

In recent years, the global footwear industry has faced increasing pressure to shift away from traditional, overseas-focused production models. Rising labor costs, supply chain disruptions, and the desire for more sustainable practices have led many brands to explore localized production alternatives.

Elastium and LaLaLand’s new Hybrid model arrives at a time when brands are seeking greater control over their supply chains. By reducing reliance on overseas manufacturers and offering flexible production capabilities, this partnership positions itself as a key player in the future of footwear manufacturing.

A Collaborative Vision for the Future of Footwear

This partnership between LaLaLand and Elastium is more than just a business venture—it’s a glimpse into the future of footwear production. By combining the best of both worlds—3D printing’s flexibility and traditional manufacturing’s scalability—the two companies have created a model that can adapt to the evolving needs of the industry.

The Hybrid model not only benefits established brands but also empowers smaller, independent designers to bring their ideas to life. With no minimum order requirements, even emerging designers can test and launch new products with minimal risk, leveling the playing field in an industry traditionally dominated by large corporations.

Conclusion

The collaboration between LaLaLand Production & Design and Elastium marks a significant step forward in the evolution of footwear manufacturing. By harnessing the power of 3D printing and combining it with tried-and-true manufacturing methods, the Hybrid model offers an agile, sustainable, and cost-effective solution for brands of all sizes.

As the Orca sneaker by ELSTM prepares to hit the market, this partnership is already making waves in the industry. With its potential to reduce costs, streamline production, and support localized manufacturing, the LaLaLand-Elastium collaboration is well-positioned to reshape the future of footwear.

FAQs

- What is the LaLaLand and Elastium partnership all about?

- LaLaLand and Elastium have teamed up to create a Hybrid footwear production model that blends 3D printing with traditional manufacturing techniques, offering faster, more sustainable, and cost-efficient shoe production.

- What makes the Orca sneaker by ELSTM unique?

- The Orca sneaker is the first product of this collaboration, featuring Elastium’s 3D-printed foam for superior comfort and energy return, combined with LaLaLand’s expertise in traditional manufacturing.

- How does the Hybrid model benefit footwear brands?

- It allows brands to produce shoes with no minimum order requirements, significantly reduces time to market, and cuts initial costs by up to 80%, making it an ideal solution for both large and small brands.

- Why is localized production important for the footwear industry?

- Localized production reduces supply chain risks, lowers carbon footprints by minimizing overseas shipping, and offers faster response times to market demands.

- What is FIDEM technology, and how does it enhance shoe production?

- FIDEM is Elastium’s proprietary technology that integrates 3D printing with traditional molding, enabling the creation of high-performance, customizable footwear with greater speed and efficiency.