Finding a pair of dress shoes that are COMFORTABLE and in the STYLE we want isn’t always easy. Tired of aching feet and spending countless hours trying on shoes, we set off on a journey to find a solution.

- The PROBLEM is STANDARD SIZING. Shoes today use a “one size fits all” approach by using a single 2-dimensional measurement, the foot length, to approximate the fit of a shoe. The problem with this method is that it IGNORES the varying shapes, girths, and other 3-dimensional attributes of a person’s foot.

- BESPOKE is the answer but is expensive, hard to find, require multiple appointments, and can take up to 6-8 months.

- The SOLUTION is MADE. We’re bringing bespoke to the digital age by offering a smartphone 3D foot scanner app, taking orders online, and delivering our shoes to your doorstep.

Gone are the days of COMPROMISING between quality, style, and fit.

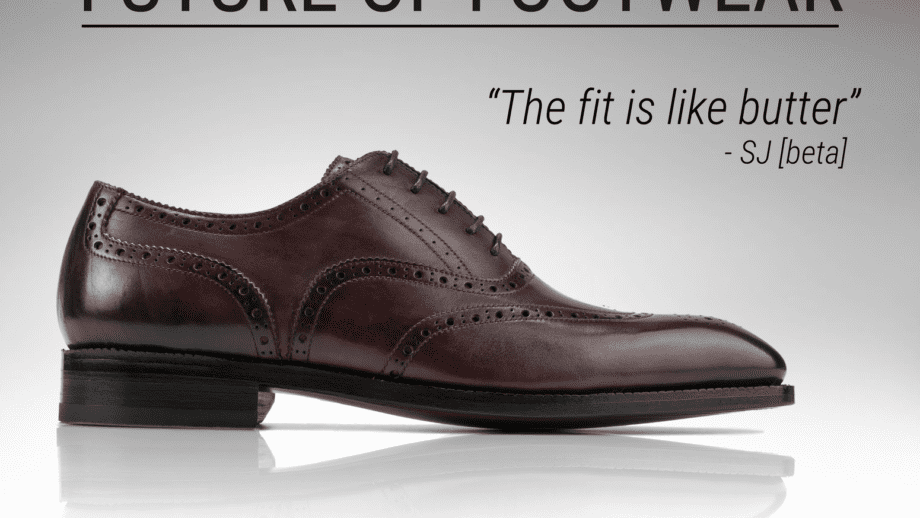

- QUALITY CONSTRUCTION – Each pair is HANDMADE and take over 200 steps & 20+ man hours.

- BUILT TO LAST – most shoes are glued together. Ours are hand stitched allowing them to be resoled

- PREMIUM CALFSKIN – We source our leather from the same Italian tannery as Berluti and Hermes.

- CUSTOM FIT – Standard sizing ignores individual anatomy. We take a combination of 14 measurements to develop a fit that follows the natural shape of your feet.

- VERTICALLY INTEGRATED – We own our factory. This allows us to offer high quality shoes at a fraction of the cost of traditional bespoke.

SCAN REQUIREMENTS

- M A D E Scan Kit

- M A D E Foot Scanner App

- A helping hand

Backers will receive a Scan Kit containing a pair of specially designed socks which must be worn during the scanning process. The Foot Scanner App will guide you through your first scan with step-by-step instructions and an easy to follow video. Scan your feet in the comfort of your own home in under 5 minutes. No shoemaker necessary.

The M A D E experience gives you complete control over the design process through our online shoe builder. We offer a variety of customization options allowing you to create a one of a kind pair that’s unique to you.

- 5 upper colors (standard & patina)

- 3 lining colors (inside)

- 3 outsole colors (bottom)

- 2 Toe shapes

- Monogram option on outsole: up to 3 letters

Two weeks after submitting your scan, you’ll receive a pair of prototype shoes to check the fit. In the situation where a major revision is required, another pair of prototype shoes will be made. From our experience, one fitting is usually enough.

After a good fit is confirmed, you’ll receive your final shoes in 4-6 weeks. Because we have your fit on file, subsequent orders will skip the fitting stage and go straight to production.

- Traditional bespoke shoemakers take 6-8 months

- We shortened it to 6-8 weeks for the first order

- 4-6 weeks for subsequent orders

HAND WELTED CONSTRUCTION

Synonymous with quality and tradition, this technique has remained the same for over 100 years and is used by only a handful of high-end brands.

DIRECT TO CONSUMER

By bringing production in house and taking orders online, we cut out the middle men and relay the savings to you.

OUR STORY

After working with over 20 manufacturers in 4 countries, we realized that nobody was willing to adopt the level of customization and quality that we wanted. In order to get it right, we needed to do ourselves.

We invested in our own facility and assembled a team of master craftsmen in Guangzhou, China, the largest footwear producing city in the world.

We’re a small team with big goals. Although we’ve made tons of progress, setting up our manufacturing facility was only the first piece of the puzzle. We’ve bootstrapped our vision of revolutionizing the bespoke shoe industry to this point, but now we need your help to piece the rest together.

SUPPORT THEIR CAMPAIGN: https://www.kickstarter.com/projects/1833418877/m-a-d-e-tech-x-bespoke