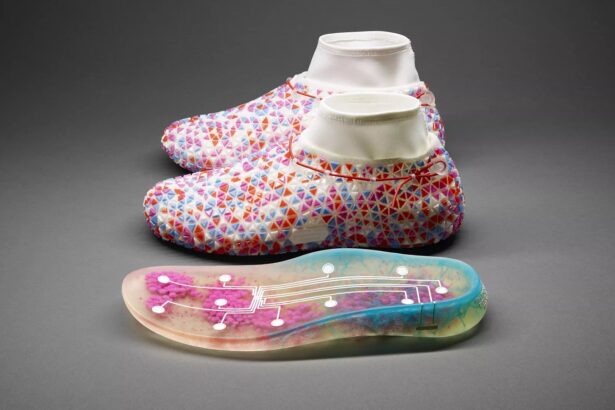

Two design students from the Academy of Fine Arts in Warsaw have designed and crafted a line of customizable 3D printed shoes. The shoes, which are made from eco-friendly materials and can be customized by the wearer through an app, were prototyped and 3D printed using ZMorph’s Multitool 3D printer. (Images: Gronowicz & Motylinska)

Source: Polish students design eco-friendly 3D printed shoes & customization app

3DShoes.com allows young designers in the US a similar opportunity to the serious disruption potential to footwear that becomes evident when you see the work of two students in Warsaw.

The team of Zuzanna Gronowicz and Barbara Motylinska delivered an extremely stylish shoe that doesn’t require glue and can be quickly assembled due to the construction technique they created that 3D printed the connecting assembly onto mesh and other fabrics. The outcome is a shoe that is very similar to an adidas Tubular model shoe.

Consider this, you visit 3Dshoes.com, select swatches of fabric, and then you choose from a selection of fasteners and joints that will allow you to shape the upper of the shoe. Those joints can now be attached to the 3D printed outsole. This creates an opportunity for the everyday person or a bespoke designer to craft replacement elements to customize and stylize their shoes in an unlimited amount of ways.

This is what Zuzanna and Barbara accomplished by creating their application. While the technology needs refining, this is a part of the market that is not being considered by the larger brands as they begin to introduce 3D printed footwear into their lines. Could adidas, Nike and New Balance be writing a future that diminishes their necessity in the near future?

Check out a few more pics of the project by using the source link to read more about the process utilized.