As a struggling footwear brand, Reebok knows it needs to be at the forefront of innovation to get its Hype back.

That’s where Bill McInnis, former NASA rocket scientist and Head of Reebok Future comes in. McInnis is leading Reebok back to relevance in the footwear by using brand new 3D printing technology with its Liquid Factory initiative.

The Liquid Factory is using new materials, including polyurethane, the same materials used in a super-ball, to deliver twice the energy return, and therefore better performance.

“The Liquid Factory is fundamentally made different, the race in 3d printing has been to get finer and finer detail to look like a cast part. A lot of 3d printing companies talk about how you can’t see the layers anymore; what we are doing is doing fewer layers, in four or five layers, and that speeds up the process,” Bill McInnis told 3Dshoes in an exclusive interview.

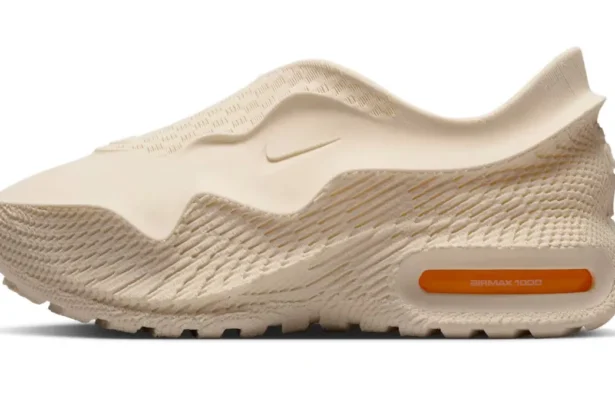

The first batch of the Liquid Factory was a 300-shoe release, focused on redoing the outsole, and which you can see from the photos, is unlike any shoe that has ever been made. Another batch is expected in 2017 and will retail for $189.95, a relative bargain compared to the price point of other major 3D shoe releases.

“Initially it will be a premium product. As you make it easier and easier for the consumer, the move will be towards widespread adoption,” he said.

“Traditionally, 3D printing has been good at making one or two of something and not a lot of things, but we are reaching an inflection point.”

McInnis is very optimistic about the future of 3D printing shoes and believes it will reach the mainstream faster than many expect.

“The idea of a project like liquid factory is it doesn’t just move manufacturing a little, it totally changes how you make things and where you make things.

In doing that that’s how you change the whole manufacturing dynamic of footwear,” he concluded.

#3DShoes #3DPrintedShoes #3DPrinted