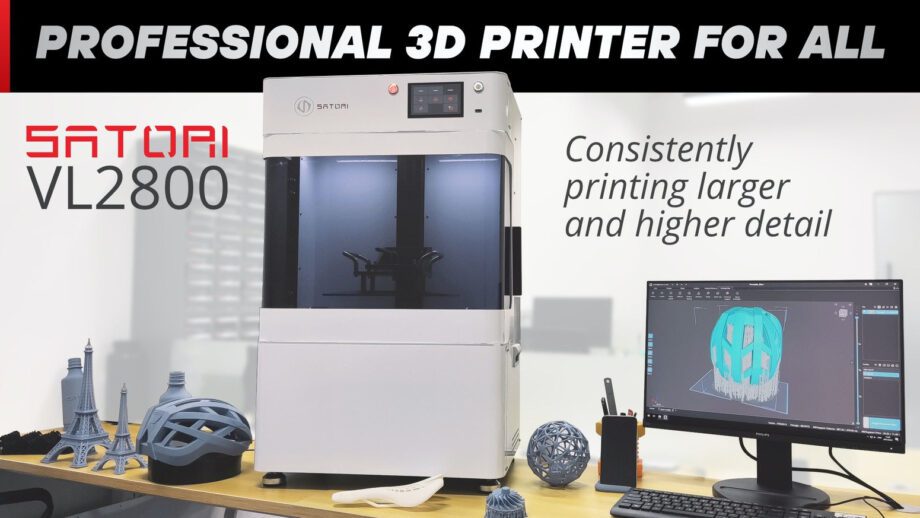

The Satori VL2800 is an industrial grade, large scale resin 3D printer designed from the ground up for high performance and reliability, with a focus on scale, precision and speed.

Visit our Youtube Channel for full timelapse videos

Scale, Precision and Speed

Satori was founded on the realisation of a new need in resin printing, between hobby and existing industrial machines. On the one hand, hobby printers are a great introduction into 3D printing, but they have to compromise on materials to hit marketing points so are not reliable enough for large prints or long operational hours. On the other hand, industrial machines, based on old patents, are expensive; typically above £10,000.

Satori builds on learnings from the 3D printer community, and produces a no-compromise printer, which combines high-quality parts with efficient cost control. Here we are: help creatives like you escape constant printer maintenance and get real work done!

Big projects printed in one go, no need to glue together

The VL2800 can print objects 29 x 15 x 30cm in size; larger than 3 loaves of bread stacked on top of each other!

Previously printing anything large at this price would require gluing together multiple prints, and spending a lot of time sanding and painting to hide the joins. Many 3D printing services won’t even take your order.

With the VL2800 you’re able to print these large items with ease, with intricate details across the hole part and minimal post processing required.

A step above in quality

We’re making a premium printer and making choices for the best quality. Our Hiwin KK linear module provides a stable platform for printing. Reducing any artefacts from layer to layer.

Highly detailed, precise and smooth finish

As this size and price you might be thinking about an FDM 3D printer (which use heated up plastic to build their models) the quality difference is completely different.

These 2 test pieces were printed in the same time, but the resin part has 4 times the detail and much better precision all over,. Not only that but you can print 100 pieces at once in the same time on the VL2800, as print time is based on the amount of layers, not how many items you’re printing at once.

We are committed to affordable printing, so we’ve made sure our shipping is as simple and transparent as possible. We’re working with EU friendly and Import friendly curriers to make sure that you are not caught out after the campaign with any additional fees.

This isn’t our first machine, but it is our first aimed at you, the creative who wants to step up in their printing. Kickstarter is so helpful for letting us build a community around this mission. Bringing the VL2800 to Kickstarter lets us make bulk purchases of all our components and aggregate shipping, meaning that our premium steel rail and 6K screen are cheaper then they’ll ever be again.

We are a young, passionate team wanting to shake up 3D printing. We’ve heard the need for entry-level industrial machines and seen the shortcomings of what’s currently out there, and are building Satori to help other small businesses and makers innovate with the power of 3D printing. Your support will empower us to make this vision happen.

Add on items

The VL2800 has everything required to start printing from day one, but for higher efficiency when printing multiple jobs or regularly changing resin, an additional build platform or resin tank is helpful. We will be selling these accessories from day 1 when the machine is available at retail.

We are offering them here on Kickstarter too so they arrive in time with your VL2800!

Why a 6K Monochrome Panel?

We didn’t like the compromise. Most of the current MSLA 3D printers in the market use a 4K panel. The problem is when the machine’s volume increases, you’d reduce the resolution because those same pixels would be spread over a larger surface area. By using the most advanced 6K monochrome panel, with a 5448 x 3060 array of pixels (51-micron resolution, smaller than a strand of hair), we can expand the machine’s build volume to a massive 278 x 165 x 300 mm without compromising the resolution.

High Precision with Industrial-Grade Z-Axis

Satori is reaching into the world of precision robotics to source our z-axis assembly. Using a Hiwin ‘KK module’ with a ball screw means we are able to guarantee consistent layer heights, and print surface quality for tens of thousands of hours of printing.

Smooth Finish with a Self-monitoring Z-Axis Motor

Using a closed-loop, self-monitoring z-axis motor means that the printer knows it has moved the correct distance for every layer. If you’ve ever seen layer-by-layer patterns in prints from other machines, it’s often caused by the motor skipping steps and altering the thickness of that layer.

Re-engineered UV lighting

As printing resolutions get higher, the consistency and uniformity of light become as important as the screen itself. At Satori, we are pushing the lighting solution beyond hobby-level printers. The Satori VL2800 stands apart from other MLSA machines in terms of light parallelism and evenness across the screen.

Factory Levelled

Unlike hobby-level 3D printers, which require users to level the print platform manually before use and adjust from time to time due to instability. Satori VL2800’s print platform is levelled in our factory ready for print right away and no adjustment is needed throughout the usage. As an industrial-grade 3D printer, Satori VL2800 focuses on streamlining the user experience, helping you focus on your creativity and get work done.

Built for easy maintenance

Don’t wait for outsourcing for your large items or lose hours assembling parts piece by piece. Working efficiently in batches reduces single item production time.

Satori VL2800 3D printer cures a whole layer at a time, so the time to print one item is the same as to print multiple items on the build platform. With a bigger build volume, we can fit much more items, thus reducing per item production time. For example, batch producing 50 buckles take 3.5 hours, resulting in a per buckle production time of 4.5 minutes.

Print large. Batch more. Process less.

3D printed prostheses are revolutionising the medical field and unlocking it to those who could not afford it. Mahdi Naim Design Lab x Satori is applying this technology to the creation of prostheses for Africa. The patient can develop his personalized prosthesis via an online platform (soon available), which is built in a week.

The hand was scanned from a real human hand of our engineer’s friend, 3D scanned using over 800 photos. It was printed by a Satori 3D printer with intricate inner bone structures and hollow, which can be injected with dyes to highlight the presentation. Satori’s hyper-detailed 3D printing at a realistic scale allows you to create everyday objects with sentimental value. Why look at 2D pictures, when you can hold a three-dimensional memory in your hand?

As a Jewellery designer with a focus on personal identity, Siobhan explores the relationship between our heritage, DNA and who we are today. Physically this idea manifests in a collection of chain-like necklaces. This large-scale articulate chain necklace was printed out by a Satori 3D printer with precise details of chains within chains. The 12 interconnected chains were printed out in one go overnight, saving time on manual labour.

3D printing can be applied to film and art industries to create vivid figures, such as those in stop motion films and sculptures. However, most current 3D printing is limited by the small size, which means large figures need to be printed in pieces (can be as many as 70 pieces) and glued together. With Satori’s new large volume 3D printer, we can print large, highly detailed models in one go and create more space for creativity.

Satori VL2800 Kickstarter campaign is supported by Elegoo’s reliable manufacturing capacity, which has successfully manufactured and shipped over 100,000 units of 3D printers worldwide in 2020. To ensure a streamlined approach, Satori has engineers on-site to supervise quality control.

“(The machine) looks really nicely made and designed…It’s gonna be something that you’d be really proud to have and display in your workshop, in your office or you might be doing some prototyping or printing jobs for different customers…And there are some notable things there…Satori is much larger in volume than Form 3…”

-Uncle Jessy (USA)

The Printer

The Resin

2 bottles, each with 1kg of Premium Modelling resin, and excellent material for capturing intense details, with good strength too, our Grey Pro resin is Precise & Durable.

Hardness: 80D

Tensile Strength: 49.1MPa

Scratch-resistant finish.

The Toolkit

A selection of tools to get started with your printer, and a step above hobby tools, A stronger wide blade spatula for removing large prints more easily, a style recommended by 3D printing YouTubers. A squeegee for cleaning out the resin tank with reduced risk of the film.

Satori (means “Enlightenment” in Japanese Zen) is a London-based startup, founded by an Oxford University graduate and female entrepreneur. Although we are a young team, we have over 20 years of combined experience in 3D printing. In our past jobs, we have worked with a wide range of 3D printers such as Stratasys, 3D Systems and Formlabs, and know the pain points of 3D printers available in the market.

In 2020, we launched our first industrial-grade 3D printer, Satori ST1600, focusing on the dental industry. At the same time, we are running a partnership programme with designers, engineers and artists all over the world to develop insight into user experience and tailor our machines to the essential needs of the creative and innovative process.

The development of the upcoming Satori VL2800 was not a process of innovating technology and trying to find a use case; on the contrary, we started with pain points discovered during our interaction with our end-users, such as the founder of Mahdi Naim Design Lab, Oxford University Robotics and Additive Manufacturing Society (OXRAM) and SWAROVSKI scholar, Siobhan Wallace from Central Saint Martins, and developed new tech product to solve their problems. Our combination of big volume and precision in this new 3D printer aims to enable more creative and quality projects at a bigger scale.

Printing is very straightforward and familiar if you’ve used other MSLA printers before. Simply slice on your computer and send to the printer over USB or Ethernet.

The VL2800’s large build platform is perfect for batch prints like these as the number of items per layer doesn’t affect print time!

SUPPORT THEIR CAMPAIGN: https://www.kickstarter.com/projects/satori3d/satori-vl2800-big-industrial-grade-3d-printer-for-creatives