These sustainable sneakers are molded from liquid cellulose—and the process can work for other items of clothing as well.

Instead of sewing or knitting, scientists at the startup Simplifyber are fundamentally rethinking how clothing and shoes are made. To make their products, the team pours liquid cellulose into a single 3D printed mold. What comes out is a fully completed shirt or sneaker. The final products are biodegradable, and the whole process reduces waste.

“Everything we’re doing is different, from start to finish,” says Maria Intscher-Owrang, cofounder and CEO of the startup, who previously worked as a designer at fashion houses, including Alexander McQueen and Vera Wang. “We design differently, in 3D. Our molds are 3D printed. Then we pour our liquid slurry that ultimately becomes a fabric-like material into those molds.”

Unlike cutting and sewing, which inevitably wastes fabric, the company’s system uses precisely the amount of material that’s needed. If it’s dyed, the dye can be added while the material is in liquid form, saving water. And when the material reaches the end of its life, it can be recycled into clothing again.

The material is made from a mix of wood pulp and other plants and biodegradable additives. It works somewhat similarly to making paper, but the resulting material is strong and durable. “We’ve created a new fabric-like material directly from a liquid that utilizes some learnings from the paper industry, but that’s really where the similarity to paper ends,” says Intscher-Owrang. “Most of our bonding strength comes from an ingredient made from food waste—it creates an effect known as cross-linking, creating bonds at the molecular level. When wet, our materials are around 94% as strong as they are when they’re dry.”

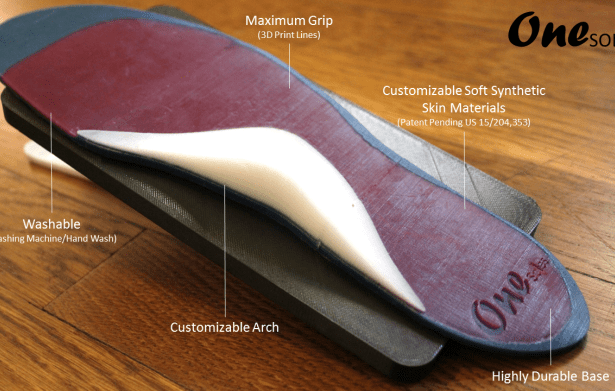

By tweaking the composition and thickness of the mixture, it’s possible to get the characteristics of fabric. “I would say it handles a lot like leather,” she says. Molding the shape means that it’s also possible to create textures on the material as it’s made, and the textures can change on different parts of the product. On a prototype of a sneaker, the designers were able to integrate different levels of thickness and padding in one step. (The soles of the sneakers were 3D printed from another material, through a collaboration with HP.)

In high-end fashion, the technique allows for “extreme customization,” she says. “You can even have a body scan where you make a mold of a person’s body, and it fits precisely.” The startup plans to begin with that end of the market. But it plans to later begin mass manufacturing, and the method can be actually more affordable than traditional apparel production.

“If you look at the supply chain of fashion, it breaks down to fiber, yarn, spinning, weaving, cutting, and sewing,” Intscher-Owrang says. “We’re actually taking over everything that comes after fiber . . . we replace it with a single process. We’re also replacing all of the transportation that normally has to happen in between those steps.”

Right now, she says, more sustainable materials are typically more expensive, and sustainable fashion tends to only be available to those who are able to pay more. But the company has a vision of replacing manufacturing at the lowest end of the market as well, making items like T-shirts. At scale, the process could theoretically produce as much in a day as a traditional factory does in one month. The team believes that it’s possible to replace as much as a third of total manufacturing. “If we can use economics as a motor to drive change, then that’s what we’ll do,” she says. “We’ll make something that’s cheaper so that these companies have an additional incentive to use it, and it makes more sense from an economic standpoint for them to use our material. And then the bonus is that it’s better for the environment.”

Simplifyber announced today that it raised a $3.5 million seed round of funding led by At One Ventures. As it begins to partner with brands, the first product, likely to be a sneaker, may come to market as soon as next year.