HY CLUTCH – Elena Kulikova

Whether its garments made for Marvel movie franchises or architectural pieces produced for jewellery manufacturing facilities, their imagination and creation all took place in this atelier, or one halfway across the world that looks just like it.

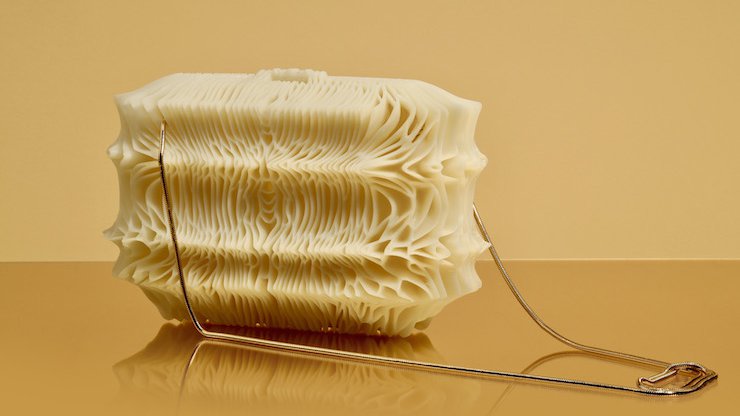

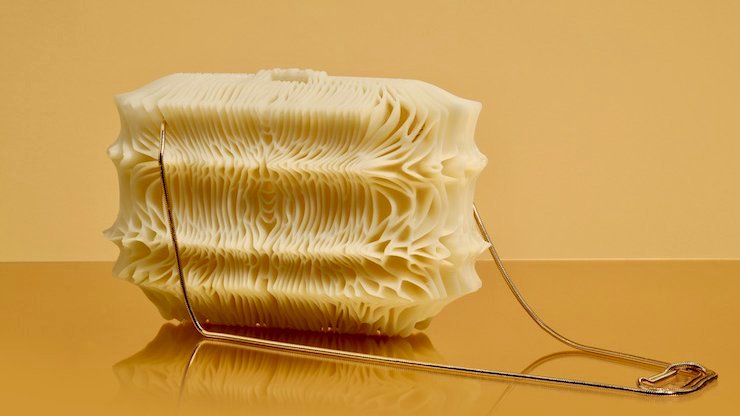

The evidence is strewn across the floor and stacked on the shelves of Julia Koerner’s Vienna studio. To the right as you come through the front door is an extrusion 3D printing system adorned with a JK3D label working away on the latest build, and beneath it a series of Lamella structures which can be used as table units or vases. Nearby are several HY clutch bags, printed in a shape reminiscent of the hymenium of a mushroom, with a resin-based printer kept in the back. There is, however, no sign of Koerner.

She dials into Vienna from Los Angeles, where she has been living for much of the last decade despite setting up her business in her hometown of Salzburg in 2015. The Austrian workspace was moved to Vienna in 2021, where the JK3D brand (established in the same year) felt it could take advantage of the local talent and resources. LA has remained the permanent location in the US because Koerner has been teaching at the UCLA’s Architecture and Design department since 2012.

Both locations exist to allow JK3D to be close to its regular clients and collaborators. The LA base can facilitate contact with Hollywood clients, while the Austrian studio puts the design brand in good proximity to the likes of Iris van Herpen, Chanel and Swarovski. Consumer fashion and home décor products, like the ones visible in the Vienna atelier, can be distributed from both facilities – a key factor in the thought process.

“What we wanted to pilot with these two locations was the idea of utilising 3D printing as a method of eliminating shipping and carbon footprint, really designing products and fashion accessories which are made on location on demand,” Koerner tells TCT. “We design between LA and Vienna, send each other the files, and then produce locally.”

Both ateliers are equipped with similar setups of machinery – office-friendly extrusion and resin 3D printing systems – making the vast array of applications even more impressive.

Koerner has been working this way for several years, using her collaborations with the likes of Van Herpen (2012-2014) to produce dresses for Paris Fashion Week and launch a business that frequently partnered with fashion designers of this ilk. This led her to work with Chanel on the redesign of a suit from 1920 in 2015, and by 2016, she was being commissioned by Marvel to 3D print costume accessories for Angela Bassett’s Queen Ramonda character in the first Black Panther film (2018) – and brought back for the sequel (2022). Concurrently, Koerner has dipped in and out of art and consumer product work, while setting up an e-commerce site for the sale of home décor and consumer fashion products.

They scratch different itches.

“A lot of these collaborations in the fashion and costume design world are very fast paced,” Koerner explains. “Fashion, especially, is on a cycle where collaborations would come up and would need to be realised within two or three months, and that not often gives me the ability to do a lot of material research or performance research.

“However, in the particular case of Black Panther, and the collaboration with Ruth Carter [the Academy Award-winning costume designer], because we had already worked on the first film, Ruth learned a lot about the 3D printing process and understood it takes time to create these complex geometries. So, there was a lot more attention towards, ‘What can we improve?’, ‘How can we advance our processes?’, ‘How can we elevate the aesthetics of the appearances of the Regal attire for the actress?’ So, there was a little bit of time where we could implement some research.”

Research, it becomes clear, is a passion of Koerner’s, and where allowed, it will come through in her work. Her collaborations in the movie industry, for example, see her operate within certain guidelines to deliver the vision of the production team, but in other projects, she is free to explore.

“The project I did with Stratasys on 3D printed fabrics,” Koerner offers as an example, “we explored what kind of geometries we can 3D print on the fabric, and this continued into longer-term research: The Re-FREAM Project, with the Arid dress as an outcome. That was nine months with various technology partners, and that gave me the ability to test materials, to test geometries, to come out with something which is supportless printing to use less material to test which fabrics would work.”

Julia Koerner/ JK3D

HY CLUTCH bags resting on JK3D Lamella table units.

The knowledge developed through projects like this help to inform the pieces that need quick turnarounds and to conform to the wants of a director. And so, although Koerner might be most renowned for her work on the Black Panther movies, it is not how she spends most of her time.

It turns out, her head is instead buried in a book as she goes on the search for organic patterns that can be found in nature. At the Vienna atelier, a new handbag as part of JK3D’s HY clutch range is being developed ahead of its official launch, while another Lamella structure is 30 minutes into a two-day print. They are both inspired by the shapes and patterns that can be found on fungi, but never for the sake of it.

With the Lamella series, for example, it takes heed of the mushroom lamella’s role as a structural element and has teamed a similar design with the material properties of a biodegradable PLA to rigidise the surface of the structure and support the thin shells that are integral to its aesthetics. These structures, which are wider at the top and bottom than they are in the mid-section, are also printed without supports.

“That means, unless there’s a print failure, we don’t have any waste material in the process of producing those, and that’s always something which I’m trying to integrate in any design I create. Looking at the aesthetic, the beauty of the project, the performance, and how to optimise the 3D print. That is a big ambition. It’s not only the design inspiration coming from nature, but also how nature over millions of years has optimised how things grow, how things are structurally optimised, how material develops. Integrating that into the design process, there’s a lot for us to learn from these natural systems.”

Not only that, she is steadfast in her belief that such natural systems need to be protected. With every project that Koerner submerges herself in, she will make sure to consider the sustainability of her work, from the design and development of products to their packaging and shipment. Take the packaging of her HY clutch bags, for example. Having initially been quoted a minimum order quantity of 500 units for a product that was always bound to evolve, Koerner determined that JK3D couldn’t consciously bulk purchase packaging of which a significant number of units may be wasted.

Instead, they decided to bring the production of packaging in-house, with JK3D now using 3D printing to create vacuum forming moulds to form sheets of recyclable plastic. It means that when they tweak the design of the HY clutch bags, they can adapt the design of the moulds in tandem, while also producing only as many moulds as they need.

“I made this fundamental rule in any project that we do that there is a sustainable aspect in it,” Koerner says. “There’s so much plastic out there already, we need to think about how we’re going to use all of this plastic because it’s not going to disappear from this planet.”

It brings us onto what the future holds for Koerner. On the to-do list is to write a book about the different projects she has worked on to tell a story of digital craftmanship across a range of disciplines, while there is also the motivation to channel some of her efforts into bio-based materials research. But what comes next could be what came first: architecture.

Teaching in the urban design department at UCLA, Koerner and her graduate students have, and will again, undertake a research project called Fit for the Future which looks into the 3D printing of sustainable façade systems for buildings.

“As buildings are getting older, they cannot keep up with the climate change and the heatwaves we have,” Koerner explains. “Some of them were designed 50 years ago, and meanwhile, our world has increased in temperature, and some of the building systems cannot work in this new environment or with these extreme situations. Instead of tearing those buildings down for lack of performance, [we] look into retrofitting them with 3D printed façade systems, meaning, could we design 3D printed surfaces which filter the air when there are fires, for example, in California? Or could we design buildings which have 3D printed panels that reflect the sunlight in a certain way so they cool the building?

“We’re really looking at how we apply this knowledge that I explored in the fashion back into architecture on a larger scale. There’s a huge scale, but I find that fascinating.”

By Sam Davies