New Balance has shown an interest in 3D printing since 2016 when it released the Zante Generate shoe, which features a 3D printed midsole. About a year later New Balance announced a partnership with Formlabs to help develop high-performance material, hardware, and process for athletic footwear. Now, New Balance has launched a new platform with the help of Formlabs’ 3D printing technology. The platform, TripleCell, delivers footwear parts that feature high performance cushioning properties. New Balance released the 990 Sport sneaker which has a 3D printed TripleCell heel and retails for $185.

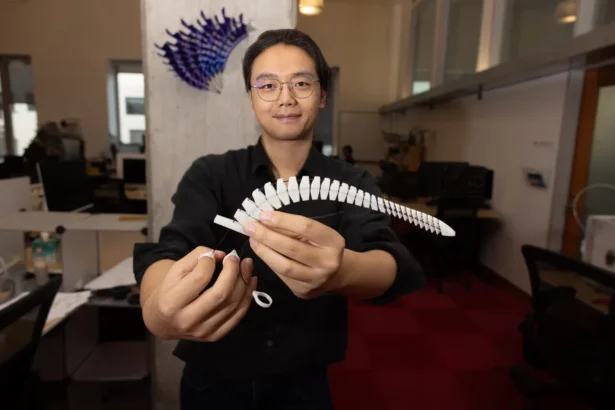

Formlabs and New Balance have been working to produce high-performance 3D materials for footwear. They have introduced Rebound Resin, which helps create springy and strong lattice structures. When used to print the material shows the same durability and reliability that you received from injection molded thermoplastics. 3D printing is changing how companies approach manufacturing, according to the Chief Production Officer of Formlabs. The 990 Sport sneaker was perfect for launching the TripleCell platform as it maintains the classic New Balance style. TripleCell was used to produce the shoe’s heel and provides the same cushioning as the traditional model but with a 10% weight reduction. The upcoming FuelCell Echo sneaker will integrate a 3D printed forefoot which is inspired by a growing focus on forefoot technology and launch of FuelCell by New Balance.

Original Article: https://www.3dprintingmedia.network/new-balance-triplecell-platform-3d-printed-footwear/

#3DShoes #3DPrintedShoes #3DPrinted