Shoe brand Vivobarefoot and material science company Balena have created a prototype trainer that is 3D-printed from compostable materials.

Unveiled today at materials conference Biofabricate, the mono-material shoe was 3D-printed from a compostable, thermoplastic material created by Balena.

Described by Vivobarefoot as “scan-to-print-to-soil”, the product will be created in a “fully automated process – scanned on phone and automatically printed”. The shoes were designed to be composted in an industrial facility.

The company believes that the shoe will form part of a process of rethinking the current industrialised system of designing, manufacturing and disposing of trainers.

“Whilst the current system might have been fit for the early part of industrialisation, it’s definitely not fit for the future” Vivobarefoot co-founder Asher Clark told Dezeen.

“In contrast to that, our goal is to create a flagship solution – one that’s on demand, rather than from stock. We want it to be fast, digital, simple and ultimately an additive process,” he continued.

“We want to build a system that creates product when you need using the only the materials you need when you need it, as opposed to an industrial system that’s making huge mountains of stock with subtractive processes.”

The trainers build on Vivobarefoot’s VivoBiome shoes, which are also 3D-printed based on scans of user’s feet, but are made from more traditional materials. Currently 176 “paying pioneers” are testing the first generation of the red VivoBiome shoes.

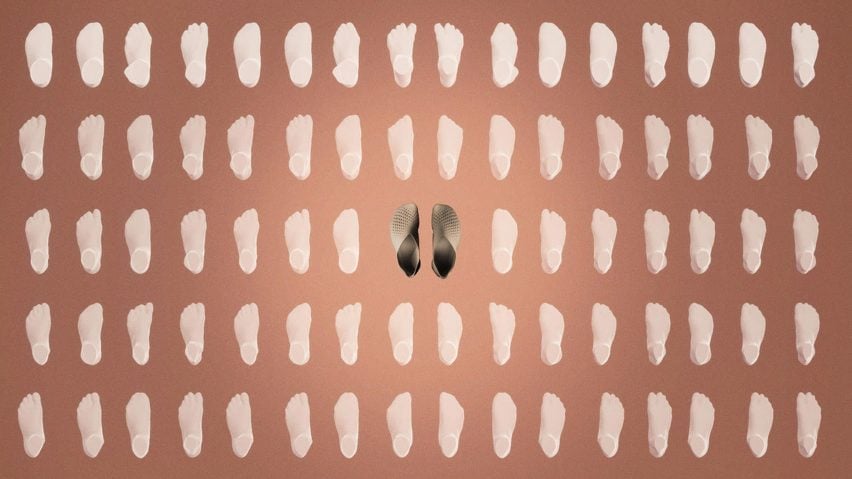

Vivobarefoot’s on-demand “scan-to-print” process sees customers scan their own feet to create shoes that are much more fitted to the shape of an individual’s feet.

“All of our feet are different in shape,” said Clark. “So even if we want to make the perfect footwear, perfect feet, it’s incredibly difficult to do that in a one-size-fits-all industrial model.”

The prototype shoes were made from BioCirflex, which was developed by Balena, and complies with international biodegradation standard ASTM D6400-04 and European biodegradation standard EN 13432.

Although the product is biodegradable and compostable, it was not designed to be composted in a back garden. Vivobarefoot expects the product to be composted in an industrial facility, and establishing this process will be one of the tasks that need to be set up before a mass launch.

“The polymers will biodegrade in any compost environment,” Balena founder David Roubach told Dezeen.

“In a compost environment you have specific enzymes that know to digest the monomers and it’s the same enzymes you have in industrial and the same one you will have in your home compost,” he continued.

“But it is not enough just to tailor the material, or to know how it will break down, you need also to work with a brand to really build an infrastructure for circularity.”

“So legally, we can say yes, put it in your home compost, and it will biodegrade. But the truth is that we don’t know how long it will take and we don’t know if you have a compost in your garden,” he continued.

“As a material science company, we understand that part of our responsibility is also to build the logic circle behind the material.”

The trainers form part of Vivobarefoot’s wider aim to radically change the footwear business as it believes that heavily cushioned shoes are damaging people’s feet. It aims to create shoes using as little material as possible.

“Millions of years of evolution have done an amazing job – your feet are amazing bits of kit, we like this idea that the best bit of technology to go into a shoe is the human foot,” said Clark.

“What we’re trying to do is make is shoes that follow your feet, we’re trying to make as little footwear as possible, to allow your feet to do what they were designed to do,” he continued.

“Shoes aren’t just trashing your health, all that fancy underfoot, cushioning and support that you’re used to under your feet is actually making them shoe shaped and weak, which negatively impacts the way you move and ultimately negatively impacts your health.”

Clark believes that the majority of “shoes are trashing your feet and the planet”. Along with reducing the amount of material that goes into shoes and considering what happens at the end of their life, he believes that the whole manufacturing process needs to radically change.

“Shoes are made in offshore industrial supply chains that have huge environmental costs,” he said.

“They’re subtractive, which means that the way industrialisation works is that you’re cutting away lots of material – there’s lots of waste in order to get to a product, so ultimately, this whole process is slow, its analogue,” he continued.

“It’s also complicated, there’s multiple layers to the supply chain and it’s almost impossible to get your hands around in terms of the true environmental impact. But it’s ultimately wasteful by design.”

Brands that have launched footwear described as biodegradable include Bottega Veneta with its sugarcane and coffee boots and Adidas with the uppers of its Futurecraft trainers.

A more experimental composition came from German designer Emilie Burfeind, whose compostable sneakers are made with a mushroom mycelium sole and a canine hair upper.

Images courtesy of Vivobarefoot.

Source: https://www.dezeen.com/2024/01/11/vivobarefoot-3d-printed-compostable-trainers-balena/