Armed with nothing but a run-of-the-mill desktop FFF 3D printer and flexible TPU filament, the mechanical engineer spent a few hours of his free time drafting the shoes up using Fusion 360 CAD software.

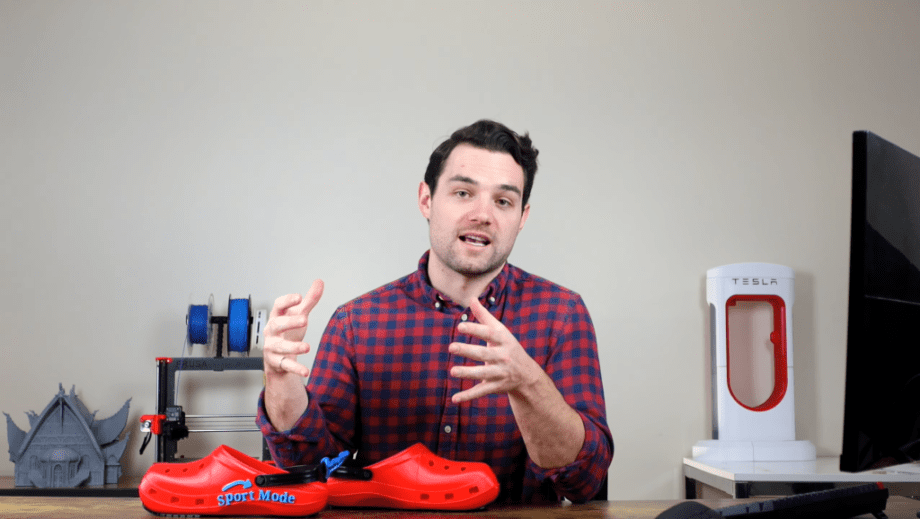

Since he didn’t even own a pair of original Crocs, the 3D models Hartley designed were based on memories and photos of the real thing. However, this allowed him to integrate a number of custom design alterations such as embossed wording, a high-grip sole, and even a spoiler on the rear. Silly? I prefer revolutionary.

Hartley said, “I didn’t spend copious amounts of time and energy in engineering school to not put those skills to good use. I usually make stuff that’s boring but every now and then I like to actually come in and make something that’s just fun.”

3D printing the Crocs

As preposterous as the project may seem, there was actually a surprisingly high level of engineering knowledge that went into making the Crocs as comfortable as possible.

When it comes to wearables like shoes, rigid polymers like ABS or PETG aren’t the best material of choice. Instead, Hartley opted for thermoplastic polyurethane (TPU), which is well-known for its flexibility and elasticity. This allows the polymer to morph under load and bounce back to its original shape when the load is taken off: just what you want from a pair of shoes.

To fine-tune the springiness of the 3D printed Crocs, Hartley also customized the thickness and density of the soles. The first iteration of the Crocs was printed with 40% infill, which is actually a relatively high density considering the application at hand. Upon testing the shoes, he found that 40% was far too rigid for comfortable long-term wear since the Crocs didn’t offer enough flexibility to conform to the curvature of his feet. After much trial and error, he eventually settled on an infill of 25% for the soles, which translated to a much more comfortable walking experience.

Additionally, since the prints weren’t completely solid, the build benefitted from less material usage and a shorter print time.