In an era where sustainability is no longer a luxury but a necessity, the 3D printing community is witnessing a transformative shift. Researchers are pioneering methods to replace conventional petroleum-based plastics with renewable, biodegradable alternatives. One breakthrough that stands out is the development of mycelium biocomposites—a technology that harnesses the natural growth of fungi to create eco-friendly, high-performance materials. In this article, we delve into the innovative research led by Danli Luo, Junchao Yang, and Nadya Peek, published in 3D Printing and Additive Manufacturing, which introduces a novel, mold-free method for fabricating these sustainable biocomposites.

I. Introduction

As the demand for sustainable solutions in additive manufacturing grows, the need for alternatives to conventional plastics becomes critical. The research on 3D-printed mycelium biocomposites not only addresses environmental concerns but also paves the way for fabricating complex, robust structures using recycled materials. At the heart of this breakthrough are three key innovations:

- • Mycofluid: A mycelium-inoculated paste formulated primarily from spent coffee grounds.

- • Fungibot: A custom, open-source hardware system designed for depositing biopastes.

- • Mycostructure: A process that enables the printed parts to incubate and self-fuse through living mycelium.

These components work in tandem to deliver a sustainable, biodegradable solution that could redefine the future of 3D printing.

II. The Promise of Mycelium Biocomposites

What Are Mycelium Biocomposites?

Mycelium biocomposites utilize the natural binding properties of fungal mycelium to convert biomass into a structurally robust material. Unlike conventional plastics derived from finite fossil fuels, mycelium-based materials are fully compostable, making them an environmentally friendly alternative.

Benefits of Mycelium Biocomposites

- • Biodegradability: These materials break down naturally without leaving harmful residues.

- • Structural Toughness: The mycelial network reinforces the biocomposite, enhancing its mechanical properties.

- • Self-Healing Capabilities: The living nature of the mycelium allows for natural “bio-welding” of printed parts, leading to seamless fusions even in complex geometries.

By leveraging natural processes, this innovative approach aligns with the growing demand for sustainable manufacturing practices in the 3D printing sector.

III. Introducing the Breakthrough: 3D-Printed Mycelium Biocomposites

Research Overview

The research conducted by Luo, Yang, and Peek introduces a method that circumvents the limitations of traditional mold-based fabrication. Their approach allows for direct 3D printing of mycelium biocomposites, eliminating the need for costly single-use molds while enabling the production of hollow structures and intricate designs.

Key Innovations

- • Mycofluid: This unique paste is formulated with a high concentration of spent coffee grounds—a recycled waste product—combined with brown rice flour, xanthan gum, and water. The formulation is optimized for uniform granularity and printability.

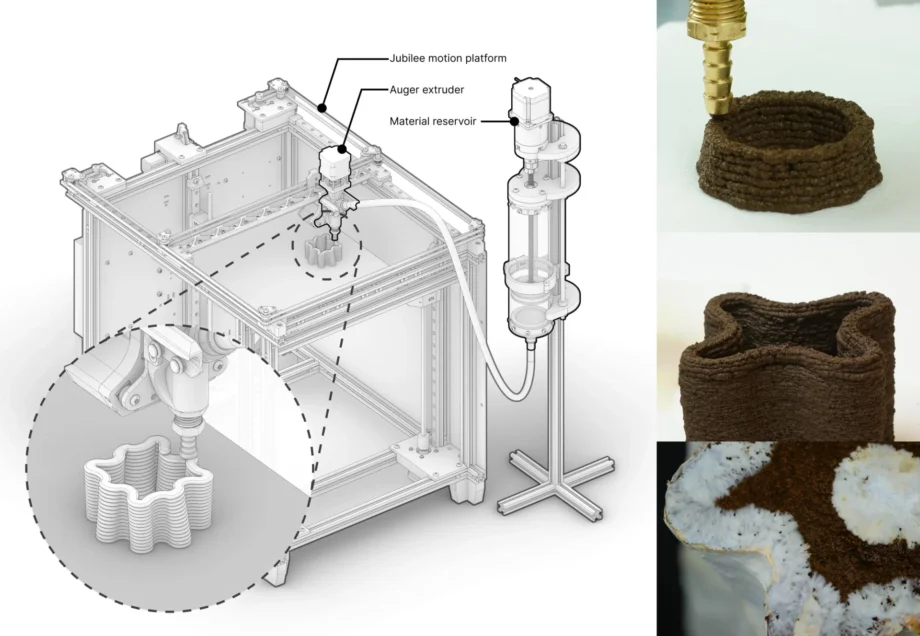

- • Fungibot: An open-source, cost-effective extrusion system that manages high-viscosity biopastes. With a material reservoir capable of handling up to 1 liter and a plunger-driven extruder equipped with precision stepper motors, Fungibot democratizes access to sustainable 3D printing technology. Explore the design on the Fungibot GitHub repository and learn more at Jubilee 3D.

- • Mycostructure: A two-step process where printed parts are incubated to promote mycelium growth, which then forms a reinforcing skin around the biocomposite. This bio-welding mechanism enables the creation of robust, self-fused structures.

IV. Materials and Methods: The 3D Printing Workflow

A. Preparing the Mycofluid

- • Ingredients: The formulation consists of spent coffee grounds (54.9% by weight), brown rice flour (13.7%), ground grain spawn (5.5%), xanthan gum (1.1%), and water (24.7%).

- • Process: After sanitizing all tools and surfaces with 70% isopropyl alcohol, ingredients are measured by weight and mixed until a uniform, extrudable paste is achieved. This paste, Mycofluid, can be stored refrigerated for several days.

B. The Fungibot System

- • Hardware Design: Fungibot features a material reservoir (a 1L polycarbonate tube) and an auger-driven printhead, both of which are designed to handle the unique properties of Mycofluid.

- • Cost-Effective Setup: With an extruder cost of around $200 and a motion platform priced at approximately $1500, Fungibot offers a low-cost alternative to commercial systems that can exceed $7000.

C. Step-by-Step Workflow

- 1. Mixing Ingredients:

- Sanitize all equipment.

- Blend dry ingredients before adding water to achieve a consistent paste.

- 2. Loading Mycofluid:

- Ensure all parts of Fungibot (reservoir, plunger, hose, auger, casing, nozzle) are sanitized.

- Load the paste carefully to avoid large gas bubbles.

- 3. Printing Process:

- Design models using Rhinoceros (McNeel) and slice with PrusaSlicer.

- Print on a waterproof hardboard lined with a paper towel using the Jubilee motion platform.

- 4. Colonization:

- Transfer prints into a sealed container and mist daily to maintain moisture.

- Incubate for 10 days to allow mycelium to fully colonize the structure.

- 5. Drying & Maintenance:

- Air-dry colonized parts at 22°C for at least 24 hours.

- Clean all printer components thoroughly with soap and water after printing.

V. Results and Discussion: Enhanced Material Performance

Hydrophobicity and Water Resistance

The incubation process leads to the formation of a mycelial “skin” on the biocomposite, significantly enhancing its water-repellent properties. The fully colonized material demonstrates a contact angle of 138°, compared to a decrease from 118° to 91° in pristine (uncolonized) samples. This robust barrier minimizes water absorption—from a 65% weight gain in uncolonized samples down to just 7% after colonization—even after prolonged exposure to water.

Mechanical Properties

Mechanical testing revealed that the tensile strength of the uncolonized biocomposite reaches 3.21 MPa, which drops to 1.41 MPa following colonization. However, the elongation at break doubles, indicating increased ductility. The compressive strength also improves, as the mycelial network acts as a reinforcing matrix, distributing stress evenly and enhancing toughness. These improvements highlight a trade-off between stiffness and flexibility that could be optimized for various applications.

VI. Real-World Applications and Case Studies

Custom Designs & Complex Geometries

The living nature of Mycofluid opens up exciting possibilities in fabricating intricate designs:

- • 3D Printing with Overhangs: A Moai statue was printed in two halves, which later fused seamlessly during incubation.

- • Tall Structures: A vase printed in three segments demonstrated excellent structural integrity and waterproofing after being assembled and colonized.

- • Hollow Structures for Packaging: Custom-fit packaging for delicate items, like a glass cup, was achieved by scanning the object, creating a mold, and printing a two-part structure that molded perfectly to its shape.

Biodegradable Applications

The potential of mycelium biocomposites extends to biodegradable applications. For instance, a mini-coffin was printed and later used to contain organic matter, demonstrating how such materials can offer both functional and environmental benefits. These examples underscore the transformative potential of integrating recycled biomass into 3D printing workflows.

VII. Challenges, Limitations, and Future Directions

Identified Challenges

- • Sterility and Air Exchange: Maintaining a contaminant-free environment is crucial, as unwanted molds can compete with the desired mycelium. Moreover, the underside of prints requires careful handling to ensure proper colonization.

- • Print Quality: The inherent graininess of recycled ingredients can limit the production of fine features. The open-loop control system in Fungibot occasionally struggles with extrusion consistency, affecting print precision.

- • Fabrication Speed: The reliance on mycelial growth means that production times are longer—often exceeding a week—compared to conventional 3D printing processes.

Future Directions

The research sets the stage for further optimization:

- • Material Tuning: Refining the balance between mycelium growth and mechanical integrity.

- • Expanding Biomass Options: Exploring additional locally sourced, recycled materials beyond spent coffee grounds.

- • Process Automation: Integrating sensors and closed-loop controls to improve print consistency and reduce manual intervention.

VIII. Conclusion: The Future of Sustainable 3D Printing

The development of 3D-printed mycelium biocomposites represents a significant stride toward sustainable manufacturing. By harnessing the natural properties of fungi and combining them with cost-effective, open-source technology like Fungibot, researchers have demonstrated a scalable alternative to traditional plastics. This innovation not only offers environmental benefits but also introduces new design possibilities in industries ranging from robotics to packaging.

As we look to the future, the promise of these eco-friendly materials challenges us to rethink manufacturing paradigms and embrace technologies that are as kind to the planet as they are innovative. The integration of living biomaterials into 3D printing heralds a new era of regenerative, adaptable design—a future where sustainability and performance go hand in hand.

IX. Additional Resources and References

- • Original Research Article: Read the detailed study on 3D-printed mycelium biocomposites in 3D Printing and Additive Manufacturing.

- • Fungibot Open-Source Project: Explore the design and development on Fungibot GitHub.

- • Jubilee Motion Platform: Learn more about the hardware platform at Jubilee 3D.

By integrating these sustainable methods into your own 3D printing projects, you can contribute to a manufacturing future that is both innovative and environmentally responsible. Join the conversation and share your experiences as we collectively push the boundaries of what’s possible in the world of eco-friendly fabrication.

Sources: Danli Luo, Junchao Yang, and Nadya Peek’s research; 3D Printing and Additive Manufacturing; Fungibot GitHub; Jubilee 3D.