3D printing (or additive manufacturing) is rapidly transforming traditional production methods and emerging as a key technology in the shift toward a circular economy. By rethinking how products are designed, produced, and recycled, 3D printing minimizes waste, enables local and on-demand production, and can even incorporate recycled or bio-based materials. Below is an in-depth, investigative look at why 3D printing projects targeting circularity and sustainability are so promising.

1. Enabling a Circular Economy

A circular economy is a system designed to minimize waste and make the most of resources. Instead of the traditional “take-make-dispose” approach, a circular economy emphasizes keeping products and materials in use for as long as possible through practices like recycling, reusing, and repairing. This model aims to create a closed-loop system where waste is minimized and resources are continually cycled back into the economy.

3D printing, also known as additive manufacturing, creates objects by adding material layer by layer based on a digital design. Unlike traditional methods that often involve cutting away material (subtractive manufacturing), 3D printing builds objects from the ground up—using only the necessary material. In the context of a circular economy, this technology offers several advantages:

- Material Efficiency: Traditional manufacturing methods often result in significant waste—imagine carving a part out of a large metal block and discarding the leftover shavings. In contrast, 3D printing uses only the material needed for the final object, meaning fewer raw materials are consumed and less waste is produced.

- Design Flexibility and Optimization: Complex, optimized designs are possible with 3D printing. Engineers can create internal structures (like lattices) that offer necessary support while using less material. This not only saves on resources but also opens up new possibilities in product design.

- Local and On-Demand Production: With the ability to produce items locally and only when needed, 3D printing reduces the reliance on huge inventories and long-distance transportation. This means lower transportation emissions and the flexibility to quickly produce customized items.

- Recycling and Reusing Materials: An exciting aspect of 3D printing is its compatibility with recycled materials. For instance, discarded fishing nets can be processed into nylon filament suitable for 3D printing, giving new life to waste that might otherwise pollute our oceans (The Times & The Sunday Times).

- Extending Product Lifespan: When a component of a product breaks, a 3D printer can quickly produce a replacement part. This ability to repair and update products extends their lifespan and reduces the need for full replacements.

By integrating 3D printing into manufacturing, industries can move closer to the ideals of a circular economy—where resources are used efficiently, waste is minimized, and products are designed with their entire lifecycle in mind.

2. Material Efficiency and Waste Reduction

3D printing is revolutionizing production by enhancing material efficiency and significantly reducing waste. Unlike traditional manufacturing, which cuts away material from a larger block (often creating a lot of scrap), 3D printing builds objects layer by layer. Here’s how this works:

2.1 Precise Material Usage

In conventional manufacturing, creating a part might involve carving it out of a larger block, resulting in leftover scraps that are thrown away. For example, machining a metal component can produce metal shavings that are discarded as waste. By contrast, 3D printing adds material only where it is needed, ensuring that nearly all the material goes into the final product. This precise usage greatly reduces material waste.

Read more on material efficiency at Eco 3DP.

2.2 Design Optimization

Advanced design software lets engineers create complex structures that are both strong and lightweight. With 3D printing, internal lattice structures or other optimized geometries can provide the necessary strength while using far less material than traditional solid designs. This not only conserves resources but also often leads to innovative product designs.

Learn about design optimization from Engineering Talk.

2.3 Reduction of Support Structures

Many 3D printing processes require temporary support structures to hold parts of the object during printing. Advances in printer technology and design software have reduced the need for these supports by optimizing the object’s orientation and structure. Fewer support structures mean less extra material is used and less post-processing waste is generated.

Discover techniques to reduce support waste in 3D Printing.

2.4 Recycling and Reusing Materials

3D printing can transform waste into new products. Recycled plastics—from water bottles to discarded fishing nets—can be processed into filaments for printers. This practice not only diverts waste from landfills and oceans but also reduces the need for new, virgin materials.

See how recycled fishing nets are turned into nylon filament at The Times & The Sunday Times.

2.5 On-Demand Production

Producing items only when they are needed minimizes overproduction. With 3D printing, manufacturers can print products locally and on demand, reducing the waste associated with unsold inventory and excess storage. This efficient approach also lowers transportation emissions since goods are produced closer to the end-user.

Read about on-demand production benefits on Caracol.

By embracing 3D printing, industries can significantly enhance material efficiency and reduce waste, paving the way for more sustainable manufacturing practices.

3. Integration of Recycled and Bio-Based Materials

3D printing isn’t just about new ways to produce items—it’s also about transforming waste into valuable resources. This technology can integrate both recycled and bio-based materials, reducing environmental impact and reliance on non-renewable resources.

3.1 Utilizing Recycled Materials

Traditional manufacturing generates a lot of waste. 3D printing offers a sustainable alternative by repurposing waste materials:

- Plastic Waste: Everyday plastics, like those from water bottles, can be recycled and processed into filaments for 3D printers. This not only diverts waste from landfills but also reduces the demand for new plastic production.

Learn more about recycling plastic for 3D printing on All3DP. - Fishing Nets: Some innovative companies are converting discarded fishing nets into high-quality nylon suitable for 3D printing. This process tackles marine pollution and provides a sustainable raw material for manufacturing.

See the detailed report from The Times & The Sunday Times.

3.2 Incorporating Bio-Based Materials

Bio-based materials come from renewable sources like plants, offering an eco-friendly alternative:

- Polylactic Acid (PLA): PLA is a popular 3D printing material made from fermented plant starches (such as corn). It’s biodegradable under industrial composting conditions and has a lower carbon footprint compared to conventional plastics.

Explore PLA and other bio-filaments on All3DP. - Wood and Natural Fibers: Some filaments combine PLA with fine particles of wood or other natural fibers, creating products that mimic wood’s appearance while being more sustainable.

3.3 Benefits of Using Recycled and Bio-Based Materials

Integrating recycled and bio-based materials in 3D printing brings multiple advantages:

- Environmental Impact: Repurposing waste and using renewable resources lowers the overall carbon footprint of manufacturing.

- Resource Efficiency: Relying on recycled and bio-based feedstocks reduces dependence on finite resources, promoting a more sustainable production cycle.

- Innovation and Customization: These materials enable creative designs and personalized products, meeting unique needs while remaining eco-friendly.

By using recycled and bio-based materials, 3D printing aligns with global sustainability efforts and helps build a more responsible, resource-efficient future.

4. Decentralized, On-Demand Production

One of the most exciting advantages of 3D printing is its support for decentralized, on-demand production—a model that contrasts sharply with traditional large-scale manufacturing.

What Is Decentralized, On-Demand Production?

Traditionally, products are made in large, centralized factories that mass-produce items in huge quantities. These items are then shipped over long distances, often leading to:

- Excess Inventory: Overproduction can result in surplus products that never sell.

- Long Supply Chains: Long-distance shipping increases costs, delays, and carbon emissions.

- Lack of Customization: Mass production typically offers one-size-fits-all products with little room for personalization.

Decentralized, on-demand production means items are produced locally, exactly when and in the exact quantity needed. 3D printing makes this possible by allowing small-scale, localized production.

How 3D Printing Enables This Model

- Local Manufacturing:

Instead of relying on giant factories, small 3D printers can be set up in local workshops, community makerspaces, or small businesses. This means products are made close to where they’re needed, reducing long-distance shipping and its associated emissions.

Read more on local manufacturing benefits from Caracol. - On-Demand Production:

With 3D printing, items are printed only when ordered, eliminating overproduction. This minimizes storage needs and ensures that resources are used precisely as required, cutting down on waste. - Customization and Rapid Repair:

Local production isn’t limited to making identical items. It also allows for customization—if a customer needs a product tailored to their specific needs, a 3D printer can adjust the design digitally and print a personalized version. Additionally, if a component breaks, a replacement part can be quickly printed, extending the product’s lifespan and reducing waste. - Responsive Supply Chains:

Decentralized production makes supply chains more agile. Because products are made on demand, companies can quickly adapt to changes in demand or sudden market trends without the risk of overproduction.

Why This Matters for Sustainability

- Reduced Transportation Emissions:

Producing goods locally means shorter shipping distances and a lower carbon footprint. - Less Waste:

On-demand production minimizes unsold inventory and associated waste, while also reducing energy consumption by avoiding overproduction. - Empowering Local Economies:

Decentralized manufacturing supports local businesses and encourages entrepreneurship, driving economic growth in communities.

5. Applications Across Industries

The versatility of 3D printing is opening up innovative possibilities in various sectors:

Construction and Architecture

- 3D-Printed Homes:

Projects like the Tecla House demonstrate how 3D printing can construct houses using locally sourced materials (e.g., earth, water, natural fibers). This method dramatically reduces construction waste and enables customized, energy-efficient designs. - Faster and Flexible Construction:

3D printing can produce complex building components on demand, reducing the need for long supply chains and lowering construction times.

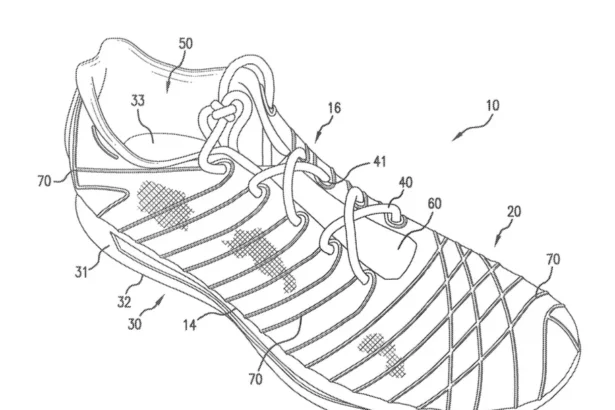

Consumer Products and Footwear

- On-Demand Production and Customization:

Instead of mass-producing items that might never be used, products like customized smartphone cases or shoes are printed only when ordered. This reduces waste and offers personalized solutions for consumers. - Innovative Footwear:

While major brands are cautious, startups are using 3D printing to create personalized sneakers that fit perfectly, produced in small batches to minimize waste.

Advanced Materials and Electronics

- Battery Components:

Companies such as Sakuu are using 3D printing to manufacture battery electrodes without the traditional “wet process,” thereby reducing waste and toxic chemical usage. - Electronic Parts:

Industries like aerospace and automotive benefit from 3D printing by producing lightweight, high-precision components on demand, reducing both material use and overall environmental impact.

Niche Industries: Fashion and Lighting

- Innovative Lighting Designs:

Designers like Lucas Zito create large-scale, artistic lamps using recycled and bio-based polymers, showcasing that sustainable practices can be both functional and visually stunning. - Customized Fashion Items:

In fashion, 3D printing enables the production of unique accessories and components that are difficult to achieve with traditional manufacturing, offering consumers personalized and sustainable options.

6. Economic and Environmental Benefits

3D printing offers a powerful combination of economic savings and environmental benefits, helping to drive a more sustainable future.

Economic Benefits

- Lower Production Costs:

Traditional manufacturing often requires large, expensive factories and a host of specialized tools. In contrast, 3D printing uses computer-controlled printers that build objects layer by layer, reducing the need for costly molds and heavy machinery. This allows small businesses—and even hobbyists—to produce products at a fraction of the cost. - On-Demand Manufacturing:

By printing items only when needed, companies avoid overproduction, reduce storage costs, and minimize the risk of unsold inventory. This efficiency translates into lower overall production costs and less waste. - Customization and Innovation:

Rapid prototyping enables designers to quickly test, modify, and perfect their products. The ability to easily customize items for individual needs not only enhances customer satisfaction but also opens up new market niches. Furthermore, producing only what is needed means fewer resources are wasted, making the entire process more cost-effective. - Decentralized Production:

Because 3D printers are compact and do not require enormous infrastructure, production can be decentralized. This local manufacturing approach cuts down on transportation costs, reduces delays, and supports local economies by empowering small-scale producers and entrepreneurs.

Environmental Benefits

- Material Efficiency and Waste Reduction:

3D printing uses only the material necessary for each product, greatly reducing waste compared to traditional methods that involve subtractive processes. Less waste means lower energy use for processing raw materials and less material ending up in landfills. - Reduced Carbon Footprint:

Local, on-demand production shortens supply chains, which significantly cuts down on the carbon emissions associated with long-distance shipping. Additionally, by minimizing overproduction, the overall energy consumption of the manufacturing process is reduced. - Use of Sustainable Materials:

3D printing supports the integration of recycled and bio-based materials—such as repurposed plastics or PLA (a biodegradable material made from corn starch). This reduces reliance on non-renewable resources and helps close the loop in a circular economy. - Extending Product Lifespan:

The ability to print replacement parts means that products can be repaired rather than discarded. This repairability extends the life of products, reducing waste and lowering the overall environmental impact.

In Conclusion

3D printing is more than a cutting-edge manufacturing technology—it’s a transformative tool that supports a circular economy by reducing waste, lowering costs, and promoting the use of sustainable materials. By enabling local, on-demand production, this technology not only meets modern consumer demands for customization but also helps protect our planet by minimizing environmental impact. As innovations continue and the technology becomes even more accessible, the role of 3D printing in building a sustainable, circular future will only grow—creating a win-win situation for businesses, consumers, and the environment.

This investigative report underscores how rethinking traditional production processes with additive manufacturing can lead to a future where economic benefits and sustainability go hand in hand.