In the ever-evolving landscape of additive manufacturing, a groundbreaking technique is emerging that promises to redefine the limits of precision and speed. Fast 3D printing of fine, continuous, and soft fibers via embedded solvent exchange (ESE) is revolutionizing the fabrication of delicate, high-aspect-ratio structures—opening new horizons in biomedical engineering, flexible electronics, and soft robotics. This article explores the science behind this innovative process, its advantages, real-world applications, and the challenges that lie ahead.

Introduction: Unveiling a New Era in 3D Fiber Fabrication

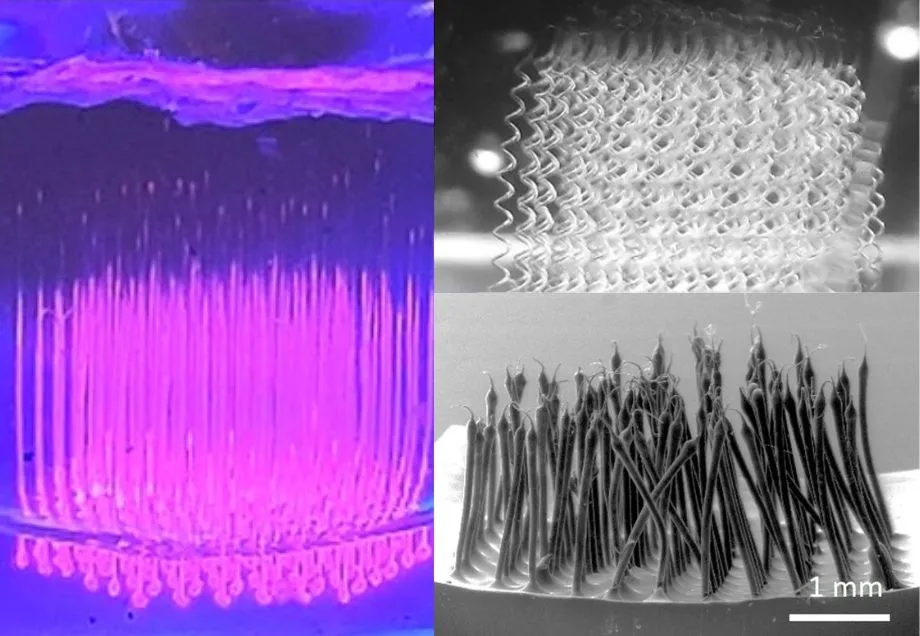

Imagine a 3D printing process that creates ultra-fine fibers with diameters as small as 1.5 µm—faster, more precisely, and continuously, without the limitations of conventional extrusion techniques. Recent research published in Nature Communications by Eom et al. introduces an advanced method known as embedded solvent exchange (ESE). This technique harnesses rapid solvent diffusion to solidify polymer inks instantly, overcoming traditional challenges such as filament breakage caused by capillary forces.

In this comprehensive article, we will cover:

- • The underlying principles of embedded solvent exchange in 3D printing.

- • The science and thermodynamics that enable the rapid formation of fine fibers.

- • The key advantages and applications of this method.

- • Current challenges and future research directions.

- • A call-to-action for innovators and researchers to explore this transformative technology.

The promise of this technology is not only in its technical achievement but also in its potential to drive sustainable and efficient production processes across multiple industries.

1. What Is Embedded Solvent Exchange in 3D Printing?

Definition & Core Concept

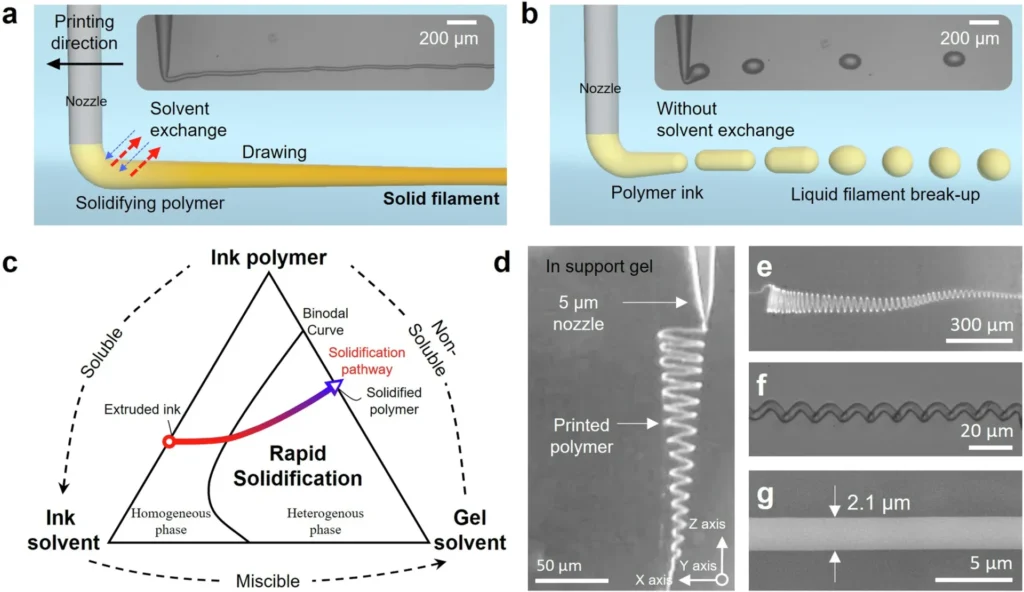

Embedded solvent exchange is a novel 3D printing method where a specialized polymer ink is extruded into a supportive gel bath that contains a carefully selected non-solvent. The critical mechanism here is the solvent exchange—where the solvent in the ink diffuses out and the non-solvent diffuses in. This process triggers immediate polymer solidification, enabling the creation of continuous, ultra-fine fibers that maintain their structural integrity and resist capillary break-up.

How the Process Works

- • Ink Preparation:

- • A carefully formulated polymer ink, designed for optimal printability and tailored rheological properties, is prepared. This step ensures that the ink has the ideal viscosity and flow characteristics required for precise extrusion.

- • Extrusion into a Gel Bath:

- • The ink is extruded through a micro-nozzle directly into a yield-stress support gel. The support gel provides necessary mechanical stability during the printing process and acts as a scaffold until the fiber is fully solidified.

- • Rapid Solidification:

- • Upon contact with the gel, a rapid solvent exchange occurs. The swift movement of the solvent out of the ink initiates an almost instantaneous phase transition, leading to the formation of a stable fiber with diameters as low as 1.5 µm and aspect ratios exceeding 1000.

Key Data:

This process has been demonstrated to produce ultra-fine fibers with exceptional precision and repeatability, as reported by Eom et al. (2025).

This innovative approach is a leap forward from conventional methods that often rely on slower thermal or UV curing processes, offering a more efficient route to high-resolution fiber fabrication.

2. The Science Behind Fast 3D Printing of Fine Fibers

Understanding the efficiency of the ESE process requires a deep dive into its scientific underpinnings, which include thermodynamics, kinetics, and rheology.

Thermodynamics and Kinetics

- • Solvent Diffusion:

- • The fundamental principle driving the process is solvent diffusion. As the polymer ink contacts the gel, the solvent begins to diffuse out into the gel bath at a controlled rate. This diffusion creates a concentration gradient that is crucial for initiating phase separation.

- • Phase Separation:

- • The interaction between the solvent and the non-solvent leads to rapid phase separation. This process results in the formation of a solid outer shell around the extruded filament, which is essential for maintaining its shape and preventing break-up.

- • Preventing Capillary Break-Up:

- • Rapid solidification is key to overcoming the Rayleigh-Plateau instability—a phenomenon that typically causes slender liquid filaments to fragment into droplets. By solidifying the filament quickly, the ESE process ensures continuous fiber formation.

Rheological Considerations

- • Viscosity Control:

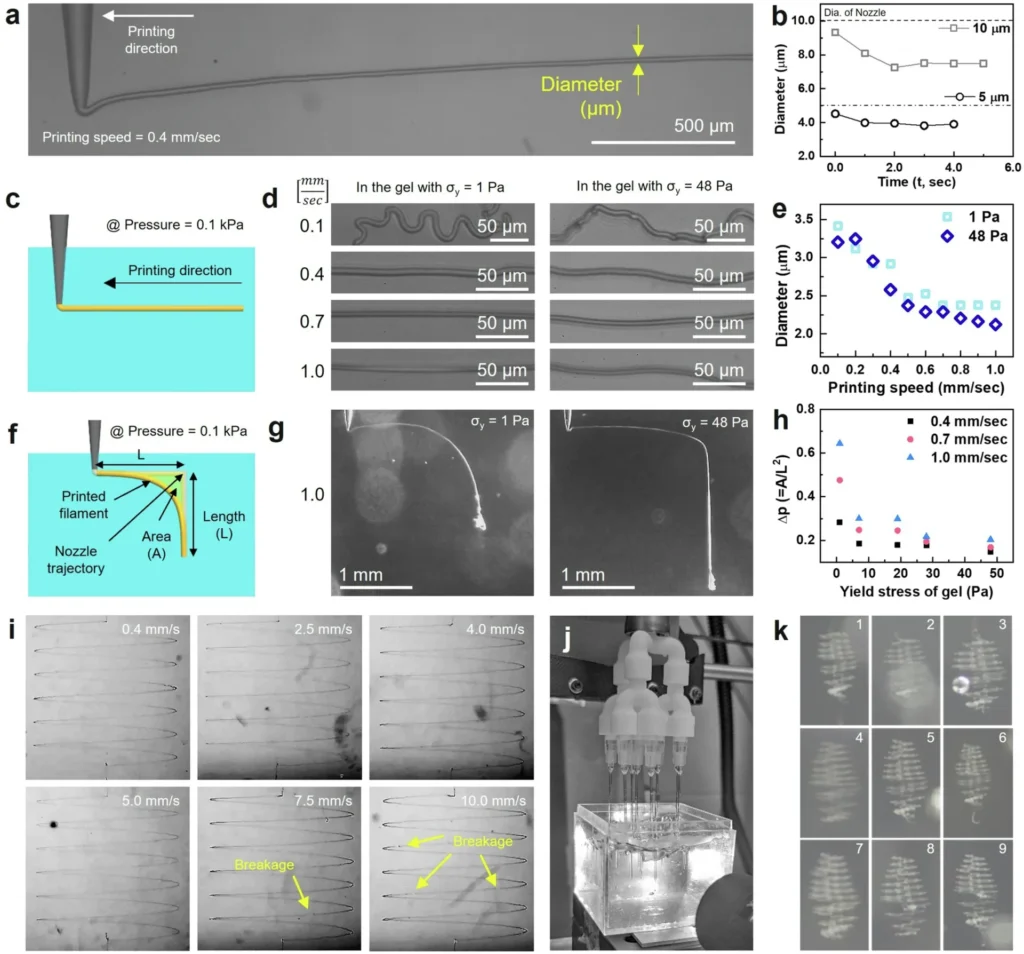

- • The polymer ink is engineered to exhibit near-Newtonian behavior at low shear rates. This consistency in flow is critical for maintaining a uniform extrusion from the nozzle.

- • Yield Stress of the Support Gel:

- • The supportive gel is formulated with a specific yield stress that is sufficient to hold the filament in place until complete solidification occurs. The interplay between the ink’s viscosity and the gel’s yield stress is a crucial factor in the overall success of the process.

Sources & Citations:

For more detailed experimental insights and numerical data on these concepts, refer to the original study by Eom et al. (2025).

3. Advantages of Using Embedded Solvent Exchange in 3D Printing

Embedded solvent exchange offers numerous advantages that position it as a transformative technology in the realm of high-precision 3D printing.

Speed and Efficiency

- • Rapid Extrusion:

- • The method enables printing speeds up to 5 mm/s, which is significantly faster than many traditional techniques. This high throughput makes it feasible for continuous, high-volume production.

- • Continuous Production:

- • Unlike batch processes that require intermittent stops, the ESE technique supports uninterrupted fiber creation. This not only improves production efficiency but also minimizes downtime.

Precision and Control

- • Ultra-Fine Resolution:

- • By producing fibers with diameters smaller than the nozzle’s inner diameter, the process achieves remarkable precision. This level of detail is essential for applications that demand intricate microstructures.

- • Complex Geometry Capability:

- • The method allows for the fabrication of freeform structures and intricate designs without the need for additional support scaffolds, enabling designers to push the boundaries of what can be printed.

Material Versatility

- • Wide Range of Polymers:

- • The ESE process is compatible with a diverse array of polymers—from soft, flexible elastomers to more rigid plastics. This broad compatibility opens up possibilities across various industries.

- • Enhanced Functionalities:

- • The process can be fine-tuned to optimize material properties such as elasticity and strength, allowing for customization based on specific application needs.

Bullet-Point Summary:

Benefits:

- 1. Fast and continuous printing.

- 2. Ultra-high precision with sub-micron diameters.

- 3. Versatile material compatibility.

- 4. Ability to fabricate complex, unsupported structures.

These advantages make embedded solvent exchange not only a technical breakthrough but also a practical solution for industries looking to scale high-precision manufacturing.

4. Real-World Applications and Implications

The practical applications of embedded solvent exchange are vast, with significant implications across multiple fields.

Biomedical Engineering & Bioprinting

- • Tissue Scaffolds:

- • This technology can be used to print delicate, flexible scaffolds that closely mimic the intricate architecture of natural tissues. Such scaffolds promote cell growth and regeneration, which are critical for tissue engineering and regenerative medicine.

- • Microfluidic Devices:

- • The production of fine, continuous fibers is ideal for creating the intricate channels and sensors required in diagnostic tools and lab-on-a-chip devices. These devices benefit from the high precision and flexibility that ESE provides.

Flexible Electronics & Wearables

- • Conductive Fibers:

- • By incorporating conductive polymers into the ink formulation, it is possible to fabricate flexible, high-performance circuits. These circuits can be integrated into wearable electronics, paving the way for advancements in portable and flexible devices.

- • Smart Textiles:

- • Ultra-fine fibers produced through this method can be woven into fabrics, enabling the development of smart textiles that combine comfort with high functionality. This opens new avenues for wearable technology that is both aesthetically pleasing and technologically advanced.

Soft Robotics & Actuators

- • Artificial Muscles:

- • The ability to produce high-aspect-ratio fibers is critical for the development of soft robotic actuators that mimic natural muscle movements. Such actuators contribute to more lifelike, responsive robotic systems.

- • Customizable Motion:

- • Embedded solvent exchange supports the creation of intricate, adaptive structures that can respond dynamically to environmental stimuli, enhancing the performance of soft robotic devices.

Sources & Data:

For detailed performance metrics and additional application examples, refer to the experimental results and case studies in Eom et al. (2025).

5. Challenges and Future Directions

While the embedded solvent exchange process represents a major leap forward in 3D printing, several challenges need to be addressed to fully harness its potential for industrial applications.

Current Limitations

- • Material-Specific Constraints:

- • Currently, the process is optimized for polymers that exhibit rapid solvent exchange characteristics. This specificity can limit the range of materials that can be effectively used.

- • Scalability Issues:

- • Transitioning from laboratory-scale demonstrations to industrial-scale production presents significant engineering challenges. Maintaining consistent solvent diffusion and filament stability across larger production volumes is a key hurdle.

- • Process Optimization:

- • Fine-tuning the delicate balance between solvent exchange rate and filament stability is a complex task that requires further research and experimentation.

Future Research Opportunities

- • Advanced Materials Development:

- • Future research will likely explore new polymer blends and composite materials that enhance fiber properties while expanding the material palette available for ESE.

- • Automation and Real-Time Monitoring:

- • The integration of advanced sensor technologies and machine learning algorithms can facilitate real-time process control. This will help ensure consistent quality and open the door for industrial automation.

- • Multi-Material Printing:

- • Developing techniques to combine different materials in a single printing process could lead to the creation of multifunctional structures with enhanced capabilities. This multi-material approach is an exciting area of future exploration.

Key Points:

Challenges:

- • Scaling up the process.

- • Enhancing material compatibility.

- • Optimizing real-time control during printing.

Future Focus:

- • Research on hybrid materials.

- • Implementation of advanced process control systems.

Conclusion: Shaping the Future of High-Precision 3D Printing

Embedded solvent exchange is setting a new benchmark in the realm of 3D printing by enabling the rapid production of ultra-fine, continuous, and soft fibers with unparalleled precision. As demonstrated by Eom et al. (2025), this innovative method is poised to revolutionize applications in biomedical engineering, flexible electronics, and soft robotics. With ongoing research addressing current challenges and exploring new material possibilities, the future of high-precision 3D printing looks exceedingly promising.

The potential impact of this technology extends beyond technical advancements—it represents a step toward more efficient, sustainable manufacturing processes that could reshape industries worldwide.

Join the 3D Printing Revolution

Are you ready to explore the cutting edge of 3D printing technology? Subscribe to our newsletter and join the vibrant community at 3dshoes.com for the latest insights and breakthroughs in high-precision 3D printing. Share your thoughts, stay informed about new developments, and be part of the innovation that is shaping the future of manufacturing.

Credits:

This article is based on the seminal work by Wonsik Eom, Mohammad Tanver Hossain, Vidush Parasramka, et al. published in Nature Communications (2025)