The Ocean Problem Meets Material Innovation

The world’s oceans are tangled with millions of tons of ghost nets — abandoned fishing gear made mostly of durable nylon. These nets can drift for decades, trapping marine life and slowly fragmenting into microplastics. While the global footwear industry has made strides in reclaiming ocean plastics for fabrics and uppers, rigid components like midsoles, shanks, and molds have remained difficult to make from recycled sources — until now.

Researchers at the Indian Institute of Science (IISc) have developed a chemical upcycling process that can turn this waste into a high-performance, reprocessable nylon suitable for 3D printing. Their study, “From ocean to opportunity: Upcycling fishing net waste into high-performance, reprocessable nylons,” was recently published in the Chemical Engineering Journal (DOI: 10.1016/j.cej.2025.168195).

From Waste Nets to Reprocessable PA-66

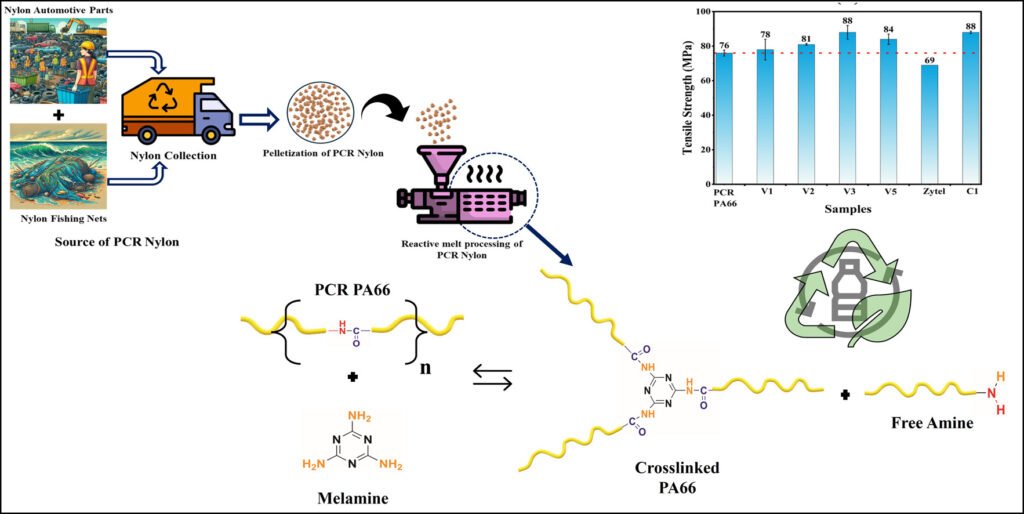

At the heart of the breakthrough is PA-66 (nylon 66), a premium engineering polymer used in automotive parts and high-durability goods. Traditional recycling of nylon simply melts and remolds the material, which degrades its molecular chains and weakens the polymer over time. The IISc team took a different route — chemical repair instead of physical reuse.

Using a compound called melamine as a cross-linker and a proprietary catalyst, they triggered a transamidation reaction inside a standard extruder. In less than two minutes, the broken chains of waste nylon were “stitched” back together, restoring and even enhancing the polymer’s mechanical strength.

“We wanted to build an industrially compatible method — not a slow lab-scale fix,” said lead researcher Prof. Suryasarathi Bose from IISc’s Department of Materials Engineering. “This reaction can happen inside conventional extruders, which means companies don’t have to retool their production lines.”

The resulting material showed excellent recyclability: it could be melted and re-processed at least three times without significant loss of strength. For a polymer as performance-oriented as PA-66, that’s a major step toward circular manufacturing.

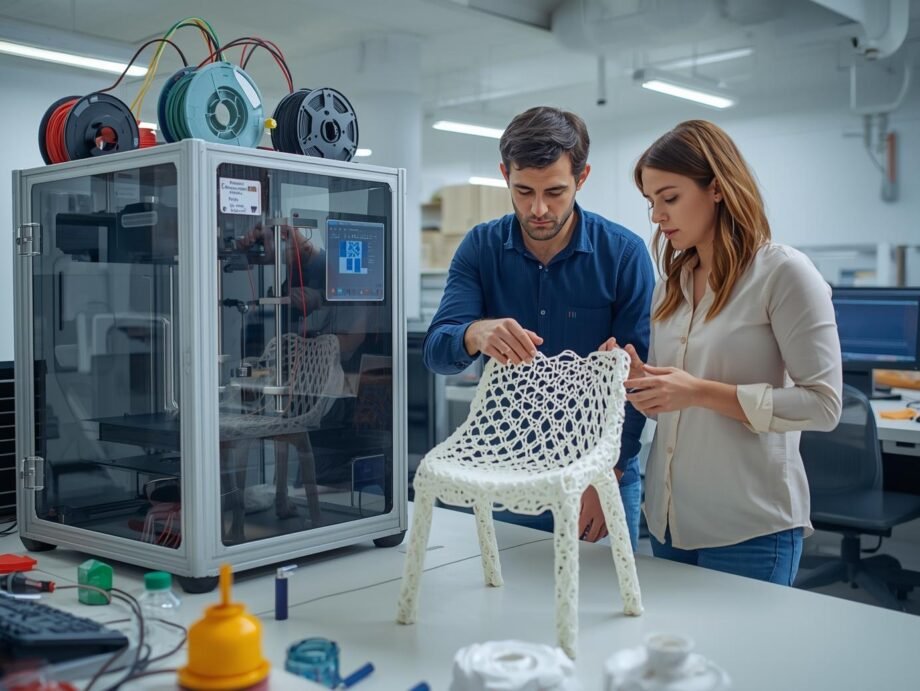

Proof by Printing: A Chair, a Speedboat — and New Potential for Shoes

To prove real-world usability, the researchers collaborated with VOiLA3D, an IISc-linked startup specializing in large-format 3D printing. They extruded the upcycled nylon into pellets and printed several demo objects — including a full-size chair and even a small speedboat hull — both built entirely from recycled material.

That demonstration is significant: it shows that industrial 3D printers can directly use this chemically repaired nylon without special handling. The material’s high melting point (around 260–265 °C) and stiffness make it ideal for load-bearing components, not flexible cushioning. But that’s precisely what footwear designers often need in structural parts — heel counters, shanks, midsoles with rigid inserts, or even jigs and molds for rapid prototyping.

What It Means for 3D-Printed Footwear

For the 3D-printed footwear market — from midsoles to custom orthotics — materials are everything. Today’s most common printable nylons (like PA-12 or PA-6) are versatile but relatively soft compared to PA-66. By upcycling waste nets into reprocessable PA-66, IISc’s method could give brands access to a more durable, circular feedstock for:

- Rigid outsole inserts and support structures

- 3D-printed molds or tooling for small-batch manufacturing

- Prototyping components that need higher stiffness and heat resistance

- Pellet-based printing systems used in industrial-scale footwear production

And since the process works within existing extrusion systems, scaling could happen faster than most lab innovations. Instead of waiting for new reactors or exotic catalysts, recyclers can potentially plug this method into their current machinery.

From Ocean to Opportunity

One of the biggest advantages of this technology lies in its feedstock abundance. Discarded fishing nets — often made of PA-66 or PA-6 — are collected in huge volumes by marine-cleanup programs worldwide. Instead of ending up in landfills or being downcycled into low-value products, these nets can become high-performance engineering polymers again.

The IISc team envisions a future where waste nylon from coastal cleanups feeds local recycling hubs, producing reprocessable pellets for regional 3D-printing facilities. For brands exploring traceable, low-carbon material sourcing, the story practically writes itself: from ocean waste to wearable innovation.

The Next Steps

Before we see “ghost-net shoes” on store shelves, a few challenges remain. Nylon is hygroscopic, meaning it absorbs moisture — a factor that can affect printing consistency. Further research is also needed to test long-term fatigue and flex properties, especially if blended with more elastic materials like TPU or EVA for footwear applications.

Still, the potential is undeniable. A fast, scalable, chemical repair process for nylon waste could transform how manufacturers think about circular feedstocks — not just in footwear, but across automotive, consumer, and marine industries.

“This isn’t just recycling — it’s rebuilding at the molecular level,” says Bose. “And it opens up entirely new ways to think about the plastics we already have.”

Why It Matters

For 3D-printing innovators in footwear, this development underscores a key shift: the next leap in sustainability isn’t only about bio-based materials — it’s about smarter chemistry that makes existing polymers truly circular. Turning ocean waste into high-performance PA-66 doesn’t just clean up shorelines; it redefines what “recycled” can mean in performance manufacturing.