Industrial 3D printing is rapidly transforming manufacturing processes across industries, and smart factories are leading the way. As precision and efficiency become paramount, integrating advanced vision systems with robotics isn’t just a competitive advantage—it’s a necessity. In this article, we explore how cutting-edge vision-based control systems are revolutionizing industrial 3D printing, address longstanding challenges, and present real-world case studies supported by academic research and industry examples.

The Evolution of Industrial 3D Printing

3D printing has come a long way since its inception. Following the expiration of key FDM (Fused Deposition Modeling) patents in 2009, the technology became accessible to a broader audience, rapidly evolving into a cornerstone of modern manufacturing. Today’s industrial 3D printers are sophisticated systems integrated with robotics, sensors, and intelligent vision systems. These advancements empower smart factories to achieve unprecedented levels of precision, flexibility, and efficiency—driving the shift toward Industry 4.0.

Challenges in Traditional 3D Printing Systems

Despite significant progress, traditional 3D printing systems still face several challenges that limit their potential:

- Spatial Constraints:

Fixed work areas often restrict the size and complexity of printable objects. - Process Control Limitations:

Without real-time feedback, printers relying solely on feed-forward control can falter when interruptions or positional changes occur. - Precision Issues:

In tasks such as resuming interrupted prints or printing on existing objects, even slight misalignments can lead to substantial translation errors and quality defects.

Research has shown that methods like Fast Point Feature Histograms (FPFH) provide a useful global pose estimation but often suffer from translation errors even when rotational discrepancies are minimal. These challenges underscore the urgent need for integrating real-time vision systems into industrial 3D printing processes.

The Vision System Revolution in 3D Printing

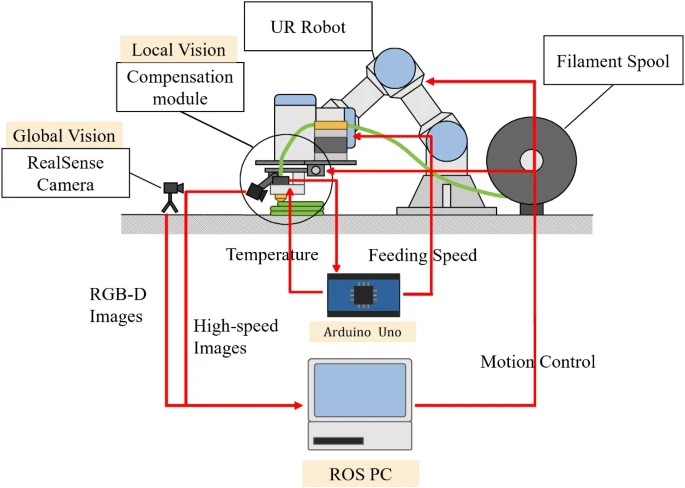

Advanced vision systems are ushering in a new era of industrial 3D printing by combining high-speed imaging, robust image processing, and robotic control to deliver ultra-precise positioning. This technology relies on a dual-stage approach:

Global and Local Pose Estimation

- Global Pose Estimation:

- How It Works:

An RGB-D camera, such as the Intel® RealSense™ D415, captures a full-scale point cloud of the work area. Preprocessing filters—like statistical outlier removal and color-based masking—are applied to isolate the relevant points. FPFH-based algorithms then generate a coarse estimation of the object’s position. - Limitation:

Although effective for providing a general location, environmental noise can affect overall accuracy.

- How It Works:

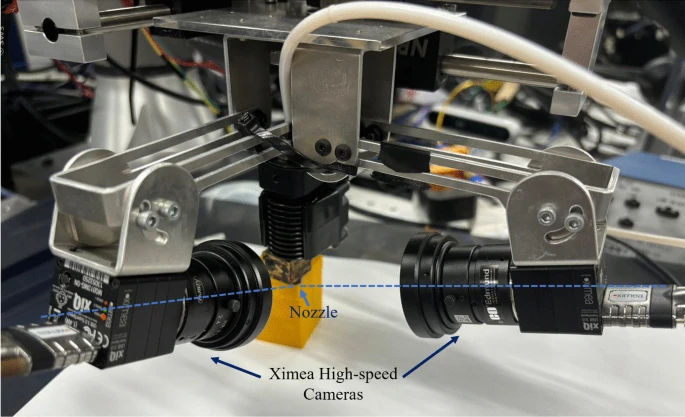

- Local Pose Estimation:

- How It Works:

High-speed cameras operating at up to 500 fps capture close-up views to refine the initial estimation. Advanced techniques such as Canny edge detection and Hough line detection are used to identify key features like edges and corners. - Sub-Pixel Accuracy:

Further refinement through sub-pixel edge-based estimation allows the system to sample positions at intervals smaller than a single pixel (often less than 0.5 mm). Gaussian-based algorithms then correct for noise to achieve sub-millimeter precision. - Expert Insight:

As detailed by Wang and Yamakawa, “the three-step estimation process—global, local, and sub-pixel—is critical for minimizing errors and achieving the precision demanded by industrial applications.”

Citation: Wang, T., & Yamakawa, Y. (2024). Enhancing precision in 3D printing for highly functional printing with high-speed vision. Int J Adv Manuf Technol, 135, 1343–1353. DOI: 10.1007/s00170-024-14594-5 (Received: 27 July 2024; Accepted: 29 September 2024; Published: 08 October 2024; Issue Date: November 2024).

- How It Works:

How Vision Integration Transforms 3D Printing

- Real-Time Feedback:

Continuous imaging ensures immediate correction of positional errors, which is essential for maintaining precision. - Adaptive Control:

The system compensates for environmental changes and object repositioning, allowing for seamless resumption of printing or additional printing on pre-existing components. - Enhanced Reliability:

By dramatically reducing print failures, vision systems minimize material waste and maximize production efficiency.

Real-World Applications and Case Studies

The transformative power of vision systems in industrial 3D printing is already evident in various sectors. Below are two real-world case studies that demonstrate the impact of these systems on manufacturing quality and efficiency.

Case Study 1: Enhanced Print Recovery in Industrial Manufacturing

In a study conducted by Wang and Yamakawa (2024), researchers simulated a common industrial scenario—an interrupted print on a 30×30 mm cuboid-shaped piece—to evaluate the effectiveness of a three-step vision-based estimation process.

- The Challenge:

In industrial settings, prints can be interrupted or the printed piece may be repositioned due to unforeseen circumstances. Traditional methods often result in significant misalignment, leading to wasted material and production delays. - The Solution:

The system employed a three-step approach:- Global Estimation: An RGB-D camera provided a coarse positioning of the object.

- Local Refinement: High-speed cameras refined the positioning by detecting corners and edges.

- Sub-Pixel Accuracy: Continuous sampling enabled the detection of the exact edge location, achieving sub-millimeter precision.

- Results:

Experimental results showed that integrating the vision system dramatically reduced translation errors, enabling the printer to resume the interrupted task seamlessly. This improvement enhanced print quality and significantly reduced production downtime. - Source:

Read the full study on Springer.

Case Study 2: Custom Printing in Smart Factories

The Dutch company MX3D is renowned for its groundbreaking projects—such as their 3D printed steel bridge—that exemplify how advanced manufacturing techniques can transform production. Although MX3D primarily uses Wire and Arc Additive Manufacturing (WAAM), their approach demonstrates the potential for vision systems in enabling adaptive manufacturing.

- The Challenge:

In dynamic production environments, printed parts often require modifications or extensions. Traditional 3D printing methods struggle to accurately resume or modify prints, resulting in inconsistencies. - The Solution:

Smart factories are now leveraging vision-based control systems that:- Monitor the print in real time.

- Adjust for any positional shifts.

- Allow printers to seamlessly add layers or repair sections with pinpoint accuracy.

- Results:

Factories employing these systems have reported significantly improved print quality, reduced material waste, and enhanced overall throughput. - Source:

Learn more about MX3D’s innovative approach on their official website.

Additional supporting research by Barnett and Gosselin (2019) and Zhang et al. (2020) further validates the effectiveness of vision feedback in large-scale printing applications, proving that these techniques are universally applicable across various industrial sectors.

Key Benefits of Implementing Vision Systems

Integrating vision systems into industrial 3D printers offers a multitude of benefits:

- Enhanced Precision:

Achieving sub-millimeter and sub-pixel accuracy dramatically reduces errors, ensuring flawless reproduction of complex geometries. - Increased Flexibility:

Vision systems allow printers to resume interrupted tasks or print on existing objects, vastly expanding production capabilities. - Improved Reliability:

Real-time error detection and correction minimize failed prints, reduce waste, and lower operational costs. - Future-Proofing Manufacturing:

As smart factories continue to evolve, integrating IoT, AI, and vision-based feedback is essential for maintaining a competitive edge.

Quick Benefits Summary:

- Real-Time Monitoring: Continuous visual feedback for immediate error correction.

- Accurate Print Recovery: Precisely resumes printing after interruptions.

- Optimized Production: Minimizes waste and downtime, enhancing overall efficiency.

Future Trends and the Road Ahead for Smart Factories

The future of industrial 3D printing is closely tied to advancements in vision technology. Key trends to watch include:

- AI and Machine Learning Integration:

Incorporating AI can further refine real-time error detection and predictive maintenance, leading to smarter, more autonomous systems. - Higher-Resolution Cameras:

As imaging technology improves, even greater detail and precision will be achievable, pushing the boundaries of what’s possible. - Expanded Material Compatibility:

Enhanced accuracy paves the way for printing with a broader range of materials—from traditional thermoplastics to metals and composites. - Enhanced Connectivity:

Vision systems will increasingly integrate with IoT platforms, offering comprehensive solutions for production management and quality control in smart factories.

An industry analyst from Robotics Insider (2023) predicts, “By 2025, the integration of vision systems in industrial 3D printing will be ubiquitous, setting new benchmarks for precision and efficiency in manufacturing.”

Conclusion: Embracing the Future Today

The integration of vision systems in industrial 3D printing is not just an emerging trend—it’s a transformative revolution that is redefining manufacturing. By overcoming traditional challenges such as spatial constraints and process control limitations, these advanced systems ensure unparalleled precision, flexibility, and reliability.

Key Takeaways:

- Enhanced Precision: Vision systems ensure every printed part meets the highest standards of accuracy.

- Operational Flexibility: The ability to adapt to changes and resume printing seamlessly reduces downtime and material waste.

- Future-Ready Manufacturing: Embracing these technologies positions companies at the forefront of Industry 4.0, ensuring long-term competitiveness.

Are you ready to revolutionize your industrial 3D printing process? Embrace the future with vision systems that offer unmatched precision and efficiency. Explore the groundbreaking research by Wang and Yamakawa in their study on Springer and discover how industry pioneers like MX3D are reshaping manufacturing. Contact our experts today to learn how you can implement these cutting-edge solutions in your production line and secure your place at the forefront of smart factory innovation.

Let’s build a smarter, more precise future together.