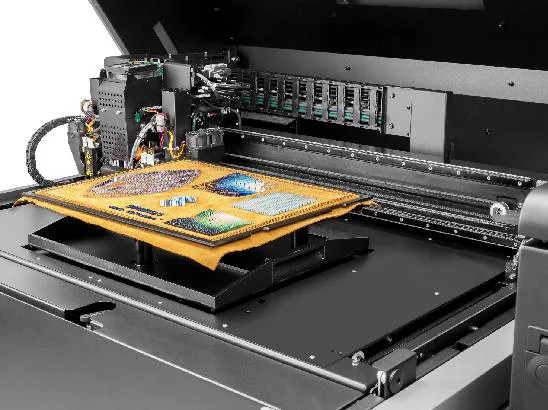

New York Embroidery Studio (NYES) is renowned for its high-end, creative apparel in New York City’s Garment District. Now, they’re taking a giant leap into the future by integrating the Stratasys J850 TechStyle 3D printer—a breakthrough in direct-to-textile printing that fuses traditional embroidery with cutting‑edge 3D printing technology. This innovative integration is detailed in Stratasys’ official press release and further highlighted by BusinessWire.

This article explores how NYES is setting new benchmarks in creative manufacturing by enhancing design possibilities, boosting customization, and driving sustainability in the fashion industry.

What is the Stratasys J850 TechStyle and Why It Matters?

The Stratasys J850 TechStyle is a state‑of‑the‑art solution that brings 3D printing directly to textiles. Unlike conventional methods, it enables precise, multi‑material printing directly onto fabric, producing intricate designs with unparalleled accuracy while blending the time‑honored art of embroidery with modern digital fabrication.

Key Benefits:

- • Direct-to-Textile Printing: Merges digital design with traditional craftsmanship.

- • Enhanced Precision: Produces intricate, tactile designs that were once impossible to achieve.

- • Industry Impact: Opens new avenues for custom‑fit, personalized apparel.

As Michelle Feinberg, Owner and Creative Director of NYES, explains, “The J850 TechStyle is an extraordinary addition to our capabilities. Our clients are thrilled by the possibilities this technology opens up—from high‑end fashion to VIP and entertainment projects.” Similarly, Zehavit Reisin, Senior Vice President at Stratasys, notes that this collaboration “demonstrates how innovative technologies can transform global design projects.” For more details on the technology, visit the Stratasys website.

Unleashing Creativity and Customization

By merging traditional embroidery with 3D printing, NYES is igniting a creative revolution. With the J850 TechStyle, designers can now:

- 1. Push Design Boundaries:

- • Complex Patterns: Create multi‑dimensional textures and intricate motifs that go beyond traditional manufacturing limits.

- • Tailored Detailing: Develop bespoke designs that capture each client’s unique vision.

- 2. Personalize Apparel:

- • Custom Fit: On‑demand production enables garments tailored precisely to individual measurements.

- • Bespoke Aesthetics: Combine digital precision with handcrafted artistry for truly unique pieces.

This fusion not only enhances design freedom but also empowers customers with one‑of‑a‑kind creations that express their personal style. Additional insights on 3D printing in fashion can be found on TCT Magazine and 3Dnatives.

Driving Sustainability in Fashion

Sustainability is a critical priority in modern fashion, and 3D printing is leading the way toward eco‑friendly production methods. The Stratasys J850 TechStyle printer significantly reduces waste by enabling on‑demand manufacturing, which minimizes excess inventory and material loss.

Environmental Benefits:

- • Waste Reduction: Uses only the precise amount of material required, reducing scrap compared to traditional cutting and sewing.

- • Energy Efficiency: Streamlined workflows reduce production times and energy consumption.

- • Eco‑Friendly Practices: Supports localized, on‑demand production that meets the rising demand for sustainable, ethical fashion.

These sustainable practices not only benefit the environment but also help brands satisfy growing consumer demands for responsible manufacturing. For further reading on sustainable fashion practices, visit Fashion Network.

Impact on the Fashion Industry & Future Trends

NYES’s integration of the J850 TechStyle is part of a broader shift in the fashion industry. As 3D printing technology evolves, it is poised to:

- 1. Transform Production Processes:

- • Hybrid Manufacturing: Combine digital printing with traditional techniques for rapid prototyping and efficient production cycles.

- • Local Production: Reduce reliance on large‑scale overseas manufacturing, lowering transportation costs and carbon emissions.

- 2. Set New Industry Standards:

- • Innovative Design: Create detailed, custom designs that set brands apart in a competitive market.

- • Enhanced Consumer Engagement: Personalization drives customer loyalty and positions brands as technology leaders.

Recent trend reports from sources like Wired and TCT Magazine affirm that these innovations are just the beginning. With emerging advancements in AI and material science, the future of 3D printing in fashion is bright.

Real‑World Applications and Expert Opinions

NYES’s successful adoption of the J850 TechStyle is already making waves. Their projects—ranging from runway collections to exclusive events like the Met Gala—demonstrate the versatility and impact of 3D‑printed embroidery. Expert opinions further bolster this trend:

- • Michelle Feinberg praises the technology for unlocking creative potential and driving sustainability.

- • Zehavit Reisin emphasizes that such innovations are redefining what’s possible in fashion design.

Additional case studies from industry sources such as 3Dnatives and TCT Magazine provide further evidence of how similar technologies are transforming custom‑fit apparel and accessory production.

Conclusion: Embracing the Future of Fashion

NYES’s integration of the Stratasys J850 TechStyle printer marks a significant milestone in the evolution of fashion manufacturing. By blending the timeless art of embroidery with advanced 3D printing, NYES is setting new standards in creativity, personalization, and sustainability.

Key Takeaways:

- • Enhanced Design Freedom: Achieve intricate, tactile designs that elevate traditional techniques.

- • Sustainable Production: Reduce waste and promote eco‑friendly, on‑demand manufacturing.

- • Industry Innovation: Lead the way by merging digital technology with classic craftsmanship.

Are you ready to witness the future of fashion? Explore how innovations like these can transform your design and production processes. Join the conversation, share your thoughts, and discover more exciting trends at 3dshoes.com.

Step into the future—where creativity meets sustainability in every stitch and layer!

References and Credits

- • Stratasys Press Release – New York Embroidery Studio Unlocks New Levels of Creativity, Customization, and Sustainability

- • BusinessWire – New York Embroidery Studio Integrates Stratasys J850 TechStyle

Image Credits: All images are credited to BusinessWire, Stratasys, and the respective original sources.