Introduction

2025 is the year 3D printing moved from experimental prototypes into shoes people actually buy and wear. Major brands shipped full-print models and printed components, designer houses deployed printed couture pieces, and performance lines used printed midsoles tuned from athlete data. This article ranks the Top 10 3D-printed shoes of 2025 by performance, design, sustainability and value. Each entry includes a concise review, core tech, who it’s for, pros and cons, and an approximate price band so you can copy and paste directly into WordPress.

How we chose the Top 10

We selected models released or actively sold in 2025 and scored them against a simple, transparent rubric:

- Performance — 30%: measurable ride metrics when available (energy return, stack geometry, weight) and credible brand claims.

- Comfort/Fit — 20%: reported fit, adjustability and usability.

- Design & Innovation — 20%: printing method, novel geometry, and production approach (one-piece vs. assembled).

- Sustainability — 15%: material choices, recyclability and brand programs.

- Price/Value — 15%: retail price vs. perceived value and market positioning.

We prioritized verified product pages, manufacturer press materials, hands-on reporting, and marketplace signals for availability.

Top 10 — Ranked

Each entry contains: model — category — price band; a one-line summary; tech bullets; who it’s for; pros/cons.

1. Adidas CLIMACOOL — Lifestyle / Mass retail — $140–$160

Summary: A widely available, one-piece lattice upper designed for extreme ventilation and a sock-like fit, representing the most visible full-print retail release of 2025.

- Tech: One-piece printed lattice upper with integrated structure; thermoplastic lattice engineered for airflow and lightness.

- Who it’s for: Urban lifestyle shoppers who prioritize breathability and minimal seams.

- Pros: Exceptional ventilation; seamless comfort; accessible price for a full-print model.

- Cons: Limited adjustability in some colorways; lattice aesthetic is polarizing.

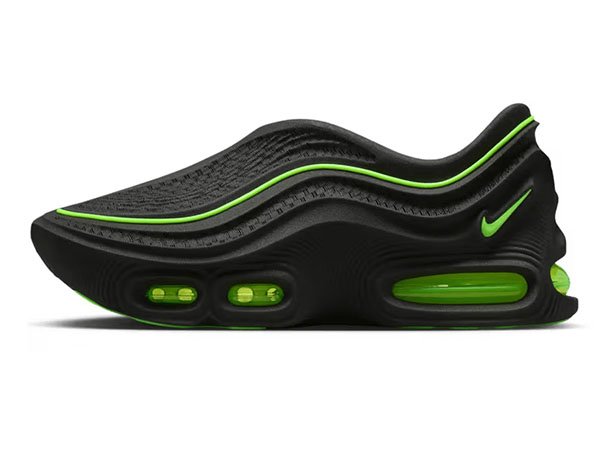

2. Nike Air Max 1000 (Zellerfeld collaboration) — Collector / Lifestyle — Limited / Premium

Summary: A heritage Air Max silhouette reworked with a near-full printed upper surrounding a classic Air unit — a high-profile tech-couture crossover.

- Tech: Single-piece TPU shell printed for contour and flexibility; retained non-printed visible Air cushion for ride characteristics.

- Who it’s for: Collectors and tech-minded sneaker fans seeking iconic styling with print innovation.

- Pros: Striking engineering; collectible appeal.

- Cons: Limited release mechanics (raffles/drops); higher aftermarket prices.

3. Nike Air Max 95000 — Streetwear/Performance — Premium

Summary: A multi-chamber Air architecture paired with a printed upper and advanced outsole compounds, blending heritage design with additive manufacture.

- Tech: Printed upper; multi-chamber Air sole; advanced outsole compound for traction.

- Who it’s for: Air Max enthusiasts and hybrid performance/streetwear buyers.

- Pros: Distinctive styling; balanced street/performance appeal.

- Cons: Heavier feel compared with minimalist runners.

4. Puma Mostro 3.D (A$AP Rocky collab) — Streetwear/Limited — $200–$300

Summary: A high-hype, resin-printed streetwear sneaker with aggressive surface geometry and strong cultural cachet.

- Tech: Resin-based high-resolution printing for full-surface detailing.

- Who it’s for: Collectors and streetwear consumers drawn to bold, limited pieces.

- Pros: Strong visual impact; solid resale potential.

- Cons: Fashion-first fit; limited availability.

5. Dior 3D-Printed Derby — Couture — Luxury

Summary: A couture demonstration of additive manufacturing: a single-piece formal shoe produced with high-resolution printing and couture finishing.

- Tech: High-resolution one-piece printed construction with manual finishing details.

- Who it’s for: Collectors, editors and luxury buyers.

- Pros: Editorial impact; collectible rarity.

- Cons: Impractical for everyday wear; premium price.

6. Adidas 4DFWD (Printed midsole variant) — Running / Performance — Performance Premium

Summary: A data-driven printed midsole designed to promote forward propulsion; a performance-focused application of lattice printing.

- Tech: Printed lattice midsole tuned for progressive compression and energy return.

- Who it’s for: Performance runners seeking a responsive ride with a distinctive printed midsole.

- Pros: Measurable performance tuning; proven athlete testing.

- Cons: Unique ride not for all runner preferences.

7. Zellerfeld Core Releases — Specialist / Multiple Categories — Varies

Summary: A series of printed models and limited runs from a specialist platform that supplied both direct-to-consumer products and brand partnerships.

- Tech: TPU/thermoplastic printed shells and lattice assemblies across models.

- Who it’s for: Early adopters and enthusiasts who favor print-first design.

- Pros: Range of styles and technical expertise.

- Cons: Variable focus on comfort vs. aesthetics across different releases.

8. Carbon-Powered Collaborations — Multiple Brands — Premium

Summary: High-precision resin lattices used by brands for midsoles or structural components; known for detail and finish.

- Tech: DLS-style resin printing with post-processing for smooth finishes and structural integrity.

- Who it’s for: Buyers who want premium finishing and precision in printed parts.

- Pros: Excellent detail; premium fit and finish.

- Cons: Some resin processes complicate recyclability.

9. On-Demand Custom-Fit Shoes (Scan + Print Services) — Premium

Summary: Foot-scanning-driven, made-to-order shoes that leverage printing for personalized fit and reduced returns.

- Tech: 3D foot scanning, parametric shoe files, printed in TPU/nylon.

- Who it’s for: Buyers who need a precise fit due to foot shape or medical requirements.

- Pros: Superior fit; lower return rates.

- Cons: Higher cost; longer lead times than off-the-shelf models.

10. Performance Hybrid Trainers (Printed Midsole + Conventional Upper) — Mid–Premium

Summary: Practical and widely adopted: printed midsoles paired with conventional uppers to balance novelty and comfort.

- Tech: Printed lattice midsole coupled with knit or foam upper for familiarity.

- Who it’s for: Everyday runners and shoppers who want printed benefits without radical design changes.

- Pros: Familiar feel with printed cushioning benefits; easier to size and return.

- Cons: Not a fully additive product; design compromises exist.

Trends & takeaways from 2025

- Retail-ready full-piece printing: Brands proved they can ship full-print footwear at scale, moving printed products into mainstream channels.

- Hybrid remains practical: Printed midsoles combined with proven uppers outperformed many full-print models in usability and acceptance.

- Designer & streetwear collabs amplified awareness: High-profile collaborations boosted mainstream interest beyond performance markets.

- Customization is growing: Foot scanning and on-demand printing grew but remain premium in cost and lead time.

- Sustainability claims are maturing: Brands are publishing more lifecycle data, yet recycling and circularity infrastructures still need development.

Performance, fit & durability expectations

- Cushioning & responsiveness: Lattice-printed midsoles can be zone-tuned for stiffness and return; their feel differs from traditional EVA but is converging in performance.

- Fit & adjustability: Full-print uppers often have a closer, sock-like fit; choose laced or hybrid models if you need adjustability.

- Abrasion & longevity: Midsole durability is strong in many printed applications; uppers’ lifespan varies by polymer and finish.

Buyer checklist: weight, stack height, printed element (upper/midsole), material specifics, return policy.

Sustainability & manufacturing impact

3D printing reduces assembly steps and can lower material waste from panels and stitching. However, energy consumption of industrial printers and post-processing (washing/curing) must be considered. Evaluate sustainability claims by asking for lifecycle or LCA data and favor mono-material designs and brands with clear take-back or recycling programs.

How to choose the right 3D-printed shoe

- Define use: running, everyday lifestyle or collectible.

- Decide printed scope: full-print upper vs. printed midsole vs. component printing.

- Assess adjustability: if you need a custom fit, prefer laced/hybrid or scanned options.

- Check policy & support: new tech requires reliable warranty and returns.

- Balance price vs. purpose: reserve high-cost custom or couture pieces for their intended use.

Where to buy & resale outlook

Primary channels: brand direct stores and websites, limited drops through partner retailers, and selected boutiques for designer releases. Resale value concentrates on limited collabs and designer pieces; performance-focused printed shoes generally retain value through usefulness rather than hype.

FAQ

A: This list highlights the top 10, including mainstream full-print entries, heritage-brand printed reinterpretations, and practical printed-midsoles for runners.

A: Yes—especially printed midsoles combined with proven uppers. Fully printed models are improving but hybrids currently offer the broadest practical performance.

A: Potentially; they reduce assembly waste and enable on-demand production, but overall sustainability depends on material choice, energy use and circular programs.

A: Lifespan varies. Printed midsoles have demonstrated solid durability; printed uppers rely on polymer abrasion resistance and finishing to determine longevity.

Conclusion

2025 marked a turning point: printed footwear is no longer fringe. Whether you prioritize performance, design, or sustainability, printed options now exist across categories. This Top 10 simplifies discovery — pick hybrids for everyday performance, full-print lifestyle models for bold design, and custom scans or couture pieces if fit or exclusivity is your priority.