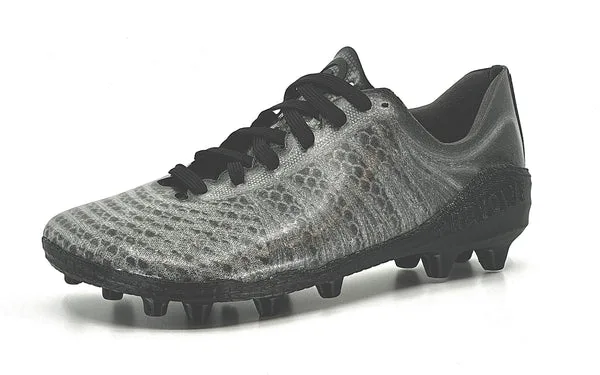

Prevolve Footwear is at the forefront of revolutionizing cleated sports footwear with its innovative 3D printed designs. The company is dedicated to creating custom-fit, minimalist cleats that empower athletes to reach their full potential while addressing common issues such as knee pain, durability, and performance. By merging cutting-edge technology with a deep understanding of biomechanics, Prevolve aims to change the way athletes experience cleated sports footwear. Their journey from concept to commercialization reflects the persistent effort to innovate, adapt, and overcome the challenges associated with 3D printing.

The Origins of Prevolve

The story of Prevolve begins with Oliver Brossmann, an aspiring professional soccer player whose path was drastically altered by two patellar knee surgeries at the age of 16. These surgeries not only changed his trajectory in sports but also inspired him to explore new ways to alleviate the physical strain athletes face. Oliver found inspiration in the book “Born to Run,” which emphasized natural movement and minimalist footwear. He began his journey into the world of 3D printed cleats, motivated by a desire to design shoes that would reduce injury risks while enhancing athletic performance.

3D Printing and Footwear: A Technological Breakthrough

The integration of 3D printing into the footwear industry represents a technological breakthrough that offers unprecedented customization, sustainability, and performance enhancement. Traditional shoe manufacturing processes involve significant material waste, while 3D printing allows for precise, on-demand production, significantly reducing waste. Additionally, 3D printing offers the opportunity to create shoes tailored to individual foot shapes, enhancing comfort and performance. This technology is particularly useful in sports footwear, where the right fit can make a significant difference in an athlete’s performance.

The Early Days: Trials and Prototypes (2010-2012)

Oliver’s early experiments with cleat modifications were a testament to his dedication to finding solutions for his knee pain. He began by sanding down the arches of traditional soccer cleats to improve foot activation. These modifications provided noticeable relief from knee discomfort and improved his performance on the field. However, the cleats were not durable, often breaking down after just a few games. This marked the beginning of his journey toward creating a more durable and effective solution.

The First Major Step: BioCleats Prototype (2014)

In 2014, Oliver field-tested his first 3D printed BioCleats prototype, a significant milestone in his journey. However, the prototype revealed that there was still much work to be done. The cleats, while functional, were far from perfect, breaking down quickly and lacking the comfort needed for extended play. Despite these challenges, the experience provided valuable insights that would inform future iterations of the design. Each prototype brought Oliver closer to realizing his vision of a shoe that not only performed well but also addressed the specific needs of athletes.

The Birth of Prevolve (2015)

By 2015, Oliver had officially founded Prevolve Footwear, dedicating himself full-time to the development of custom-fit, minimalist cleats. Working alongside designers, marketers, and entrepreneurs in Seattle, Oliver refined both his brand and his technology. His goal was clear: to create cleats that would empower the human body by enhancing natural movement and reducing the risk of injury. This marked the beginning of a new chapter in the development of 3D printed footwear, with a focus on customization, performance, and sustainability.

Testing and Iterations: The Path to Perfection (2015-2016)

Despite the promising start, Oliver faced numerous challenges in the development of fully 3D printed cleats. Issues such as overhangs, durability, moisture exposure, and the use of flexible filaments plagued the early prototypes. Many of these cleats broke after only a few hours of use, and some were simply too uncomfortable to wear during games. However, Oliver remained undeterred, understanding that each failure brought him closer to a viable solution. This period of intense testing and iteration was crucial in refining the design and functionality of Prevolve’s cleats.

Breakthrough with BioRunners (2017)

In 2017, Oliver shifted his focus from cleats to a more straightforward product: the BioRunner. This fully 3D printed, custom-fit shoe was designed with comfort and performance in mind. While the BioRunners were not intended for cleated sports, they represented a significant step forward in Prevolve’s development. The shoes were well-received, with over 30 pairs sold. However, production challenges and durability issues continued to pose significant hurdles. Despite these setbacks, the BioRunner served as a proof of concept, demonstrating the potential of 3D printed footwear.

Prevolve Resurrections: A New Chapter (2020)

After a brief hiatus, Oliver resumed his work on 3D printed footwear in 2020, this time enlisting the help of Reijer Kolle. Together, they focused on developing more reliable manufacturing processes, including fused TPU assembly and improved 3D scanning techniques. These advancements allowed Prevolve to create shoes with better durability and comfort, bringing them one step closer to commercial success. The collaboration between Oliver and Reijer marked the beginning of a new era for Prevolve, characterized by more sophisticated technology and a renewed commitment to innovation.

Establishing the 3D Printing Factory (June 2023)

In June 2023, Prevolve took a significant step forward by opening its own 3D printing factory in Seattle. This facility marked a turning point for the company, allowing for increased production capacity and greater control over the manufacturing process. With the ability to produce two pairs of BioCleats per week, Prevolve was finally in a position to meet growing demand. The factory also enabled the company to experiment with new designs and materials, further enhancing the performance and durability of their cleats.

Entering the Professional Sports Arena (September 2023)

In September 2023, Prevolve made headlines when NFL cornerback Noah Igbinoghene became the first professional athlete to wear BioCleats on the field. This milestone represented a significant validation of Prevolve’s technology and design. Noah’s positive experience with the cleats, particularly their comfort and lightweight feel, confirmed that Prevolve was on the right track. This breakthrough moment opened the door for other professional athletes to consider BioCleats, paving the way for wider adoption in sports such as soccer, football, baseball, and rugby.

Revolutionizing Cleated Sports: BioCleats (November 2023)

By November 2023, Prevolve had redesigned the BioCleats to improve durability and comfort. Field testing across various sports demonstrated the versatility of the cleats, with athletes praising their performance on different surfaces. Prevolve’s commitment to customization and sustainability continued to set them apart from traditional footwear manufacturers. The company’s ability to create cleats tailored to each athlete’s foot shape allowed for improved comfort, reduced injury risk, and enhanced performance.

Sustainability and Customization: Prevolve’s Contribution to the Footwear Industry

One of the most significant advantages of 3D printed footwear is its contribution to sustainability. Traditional shoe manufacturing processes generate a considerable amount of waste, whereas 3D printing allows for on-demand production with minimal material waste. Prevolve’s commitment to sustainability is evident in their use of eco-friendly materials and their focus on creating long-lasting, durable products. Additionally, the company’s ability to customize each shoe to the wearer’s foot shape ensures a better fit, which can help prevent injuries and improve overall performance.

Challenges in Scaling and Commercialization

Despite its many successes, Prevolve continues to face challenges in scaling its production and commercializing its products. The 3D printing process is still relatively slow, limiting the company’s ability to meet growing demand. Additionally, the cost of producing custom-fit shoes remains higher than that of mass-produced footwear, making it difficult to compete with traditional manufacturers on price. However, as 3D printing technology continues to evolve, Prevolve is optimistic that these challenges will be overcome, allowing them to reach a broader audience and expand their product offerings.

Conclusion

Prevolve Footwear’s journey from concept to commercialization is a testament to the power of innovation, persistence, and a commitment to improving the athlete’s experience. By leveraging 3D printing technology, Prevolve has created a product that not only performs at the highest level but also contributes to sustainability and customization in the footwear industry. As the company continues to refine its designs and scale its production, it is poised to revolutionize the world of cleated sports footwear, offering athletes a new level of comfort, performance, and durability.

Stay Connected with Prevolve Footwear

To stay up-to-date with the latest developments, product launches, and behind-the-scenes looks at Prevolve Footwear, follow us on social media! Join our community of athletes, innovators, and sustainability advocates, and be the first to hear about exciting updates.

- Facebook: Prevolve Footwear

- Twitter: @Pre_volve

- Instagram: @prevolve_

- LinkedIn: Prevolve Footwear

- YouTube: Prevolve Footwear

- TikTok: @prevolvefootwear

Whether you’re passionate about 3D printing technology, minimalist design, or sustainable sportswear, we invite you to connect with us across all platforms and join the movement toward the future of footwear!

FAQs

What is Prevolve Footwear known for?

Prevolve is known for its 3D printed, custom-fit minimalist cleats that are designed to enhance athletic performance while reducing the risk of injury.

How does 3D printing improve cleated shoes?

3D printing allows for the creation of custom-fit shoes tailored to the athlete’s foot shape, providing better comfort and performance. It also reduces material waste, making the process more sustainable.

What are the challenges of making fully 3D printed shoes?

Some of the challenges include ensuring durability, improving moisture resistance, and scaling production to meet demand.

What are BioCleats and how do they work?

BioCleats are Prevolve’s flagship 3D printed cleats, designed to be lightweight, durable, and customized to the athlete’s foot for optimal performance.

Why are professional athletes turning to BioCleats?

Professional athletes like Noah Igbinoghene are choosing BioCleats for their comfort, lightweight feel, and ability to reduce injury risk.

How does Prevolve contribute to sustainability in the footwear industry?

Prevolve uses 3D printing to reduce material waste and create durable, long-lasting products, contributing to a more sustainable approach to footwear manufacturing.