Introduction — From “Tangled Spaghetti” to Self‑Correcting Shoes

Picture hitting Print on a new sneaker concept, grabbing a coffee, and returning to find a flawlessly printed pair—no filament bird’s‑nest, no warping, no wasted hours. That once‑sci‑fi scene is becoming routine thanks to AI‑driven 3D printing. Sensors, machine‑learning algorithms, and cloud “brains” are turning formerly “dumb” printers into partners that watch, learn, and correct themselves in real time. For footwear makers—from basement hobbyists to global brands—the payoff is faster design cycles, truly custom fits, and dramatically greener production. This deep dive shows how AI is teaching printers to think for themselves, why it matters for shoes, and what’s coming next.

1. What Exactly Is AI‑Driven 3D Printing?

- Brains + Brawn – On‑board cameras, laser micrometers, and IoT sensors feed print data to neural‑net models that adjust temperatures, speeds, and toolpaths on the fly.

- Fleet Learning – Printers upload results to the cloud; a fix discovered in one shop can improve machines worldwide overnight.

- Proof Point – Markforged’s Blacksmith system scans every layer with an onboard laser and tweaks future prints, achieving first‑try dimensional accuracy within ±60 µm.

2. Self‑Learning Printers: From “Spaghetti” to Spec

2.1 Consumer Level

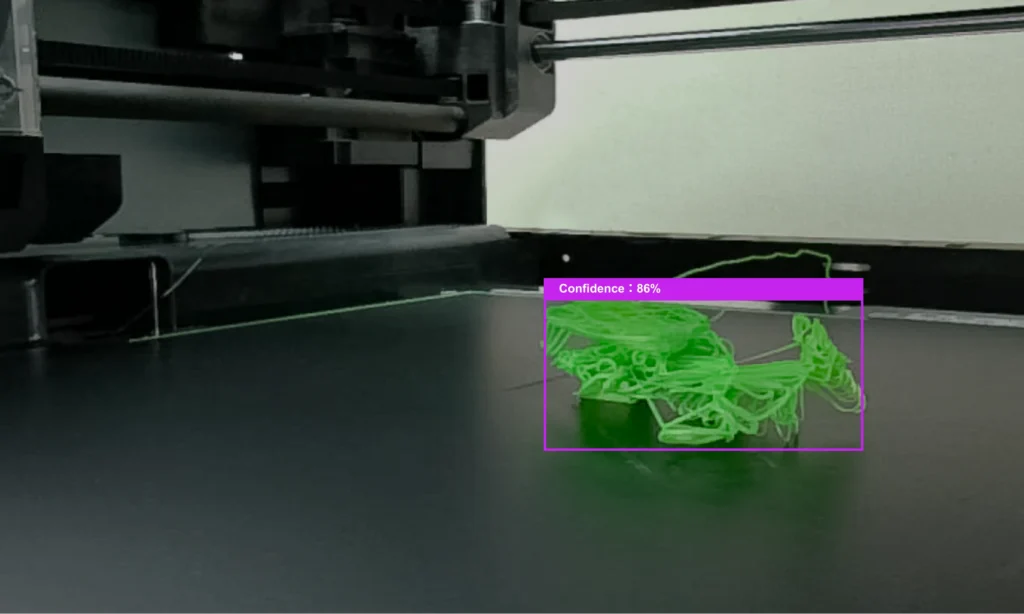

- Bambu Lab X1 uses AI vision and LiDAR to spot first‑layer flaws and mid‑print “spaghetti,” pausing jobs before disaster strikes.

- Obico (formerly The Spaghetti Detective) brings similar deep‑learning failure detection to any webcam‑equipped printer; open‑source tests show 93 % accuracy on common failure modes.

2.2 Industrial Scale

- Blacksmith closed‑loop control lets factories ship “born‑qualified” parts without post‑print inspection.

Result: Hobbyists waste less filament; factories slash scrap and rework—turning printers into 24/7 employees, not projects that need babysitting.

3. Generative‑Design Sneaker Labs

| Brand / Startup | AI Workflow | Time to Prototype |

|---|---|---|

| Nike A.I.R. | Text prompts → generative lattices → large‑size prototypes for pro athletes | Days, not months |

| Syntilay | Vizcom + proprietary AI automates 70 % of design work; shoes printed by Zellerfeld | ≈ 3 months |

| Adidas 4D | Carbon’s algorithmic lattice engine optimizes cushioning & energy return | Ongoing inline updates |

AI pumps out dozens of “impossible” lattice midsoles or dragon‑scale uppers; designers curate the best ideas, and printers bring them to life overnight.

4. Personalized Fit at Scale

- Biomechanics research at MIT shows algorithms can predict how sole stiffness, geometry, and foam chemistry affect a runner’s energy cost—paving the way for algorithm‑tuned shoes for every gait.

- Phone‑scan sizing is already live: Syntilay’s slides require a smartphone foot scan; production delivers in about five weeks.

- Zellerfeld customers reserve a slot with a small deposit, then receive shoes printed to each foot’s scan—most buyers choose personalized fits.

5. Autonomous Print Farms & Predictive Maintenance

- Zellerfeld operates a large farm of bespoke TPU printers; its designer portal lets creators upload shoes as easily as a video, eliminating minimum order quantities.

- Emerging machine‑learning recommender systems tune speeds and temperatures across fleets, boosting quality while cutting downtime.

Metric: Early pilots report uptime nudging 99 % once predictive analytics schedule nozzle swaps before they clog.

6. Sustainability Wins

- Life‑cycle studies with the startup HILOS show 48 % less carbon and 99 % less water versus legacy shoe manufacturing.

- Additive manufacturing uses only the material you need; AI topology optimization can shave another 40 % off per‑part polymer use.

- Local print hubs replace global freight; digital files travel, not pallets.

7. Business & Maker Playbook

- Brands – Drop micro‑collections tied to live events; co‑create with athletes in real time.

- Start‑Ups – Spin up a line on platforms such as Syntilay or Zellerfeld without molds or inventory.

- Hobbyists – Sell STL sneaker mods online; Obico and low‑cost webcams provide pro‑grade QA.

- Service Bureaus – Offer on‑demand lattice midsoles, orthotics, or spare parts with AI‑designed tuning.

8. Challenges & What’s Next

- Throughput – A midsole still takes hours; researchers aim for sub‑five‑minute cycles via multi‑toolhead and continuous‑liquid printing.

- Materials – Industry needs softer, recyclable, multi‑material prints to build uppers and soles in one shot.

- IP & Ethics – Who owns an AI‑generated shoe design: the algorithm, the prompt writer, or the brand?

- On the Horizon – Edge‑AI chips on printers, real‑time simulation while printing, and closed‑loop recycling with material‑recognition vision.

Frequently Asked Questions

Not anymore. Many desktop printers now ship with AI vision and failure‑detection built in, and open‑source tools bring similar smarts to older machines with a basic webcam.

Early testers report comfort on par with premium custom orthotics. Precision depends on the quality of the foot scan and the calibration of the printer, but algorithms continuously improve with more data.

Most current pairs are printed in single‑material TPU, which is fully recyclable. Research into bio‑based polymers and AI‑optimized recycling processes aims to make circular footwear mainstream.

No—AI expands creative options and automates grunt work. Designers still guide aesthetics, brand voice, and user experience.

Conclusion—Your Next Sneaker Could Print Itself

AI is quietly giving 3D printers intuition: they see, decide, and correct while lattices of code become lattices of polymer beneath the nozzle. For footwear, that means shoes that fit like data points, launch as fast as software updates, and tread far lighter on the planet. Whether you’re an indie designer, a sneakerhead, or a global brand strategist, now is the moment to start that conversation with your printer—because it’s finally ready to talk back.

Enjoyed the deep dive? Subscribe to 3DShoes for more future‑forward footwear insights and share your AI‑printing wins in the comments.

Sources

- BBN Times – “Tomorrow’s Tools: How AI Is Quietly Teaching 3D Printers to Think for Themselves”

https://www.bbntimes.com/technology/tomorrow-s-tools-how-ai-is-quietly-teaching-3d-printers-to-think-for-themselves - 3D Printing Industry – “Markforged Launches AI‑Based Blacksmith Software for 3D Printing”

https://3dprintingindustry.com/news/markforged-has-launched-its-new-ai-based-blacksmith-software-for-3d-printing-186661/ - 3D Printing Industry – “Open‑Source Spaghetti Detective Detects Failed Prints Through Webcam”

https://3dprintingindustry.com/news/open-source-spaghetti-detective-ai-software-detects-failed-prints-through-webcam-170623/ - Unionfab Blog – “How Major Brands Are Shaping 2024’s 3D‑Printed Shoes”

https://www.unionfab.com/blog/2024/07/3d-printed-shoes - 3Dnatives – “Syntilay Combines 3D Printing and AI to Create the Footwear of the Future”

https://www.3dnatives.com/en/syntilay-3d-printing-and-artificial-intelligence-footwear-200520254/ - 3DPrint.com – “HILOS Launches Studio OS for AI‑Driven 3D‑Printed Shoe Design”

https://3dprint.com/309119/hilos-launches-studio-os-for-ai-driven-3d-printed-shoe-design/ - 3DPrinting.com – “Nike’s RTFKT Debuts Final 3D‑Printed Sneaker Collection Before Closure”

https://3dprinting.com/news/nikes-rtfkt-debuts-final-3d-printed-sneaker-collection-before-closure/