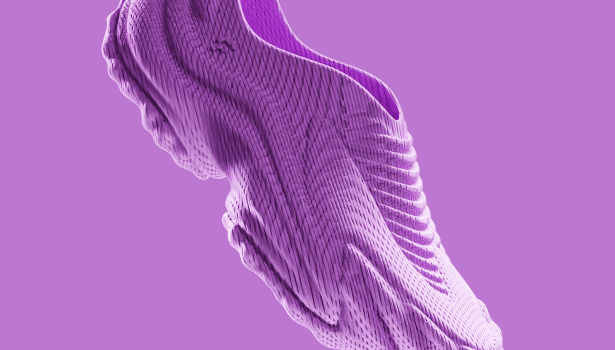

Heron Preston is venturing into the world of 3D printed footwear. The director of the company has teamed up with Zellerfeld Shoe company Inc., who is focused on 3D printing manufacturing solutions for footwear. The partnership combines Preston’s vision, designs from footwear concepts, and Zellerfeld’s 3D printing technology. Zellerfeld uses a commercial 3D printer called the “Monolith.” Standing 6-feet tall, the Monolith is large, but low-cost compared to other industrial units. The footwear material is a thermoplastic polyurethane flexible polymer that uses no glue or water in construction. Environmentally, the process also works well for reducing shipping impact and shortening delivery times.

The 3D printed shoes can take 24 hours or longer to be made, making it more timely than traditional footwear. But the Monolith machine can print a shoe which is 100 percent recyclable and custom-fitted to the wearer. When a pair of shoes break down or the consumer no longer wants it, they can send it back. The shoe will then be broken down and the materials will be used to print another shoe. There is no set launch date for the footwear collaboration yet because it is still in the early stages. The vision is to have a place in New York City where people can come in, scan their feet, and have their shoes on the spot. I look forward to seeing where Preston and Zellerfeld take their project.

Original Article: https://wwd.com/sustainability/innovation/heron-preston-3d-printed-shoes-footwear-sustainability-zellerfeld-shoe-company-1234633686/