🧭 The 2025 Shift: From Factory Floors to Footwear Studios

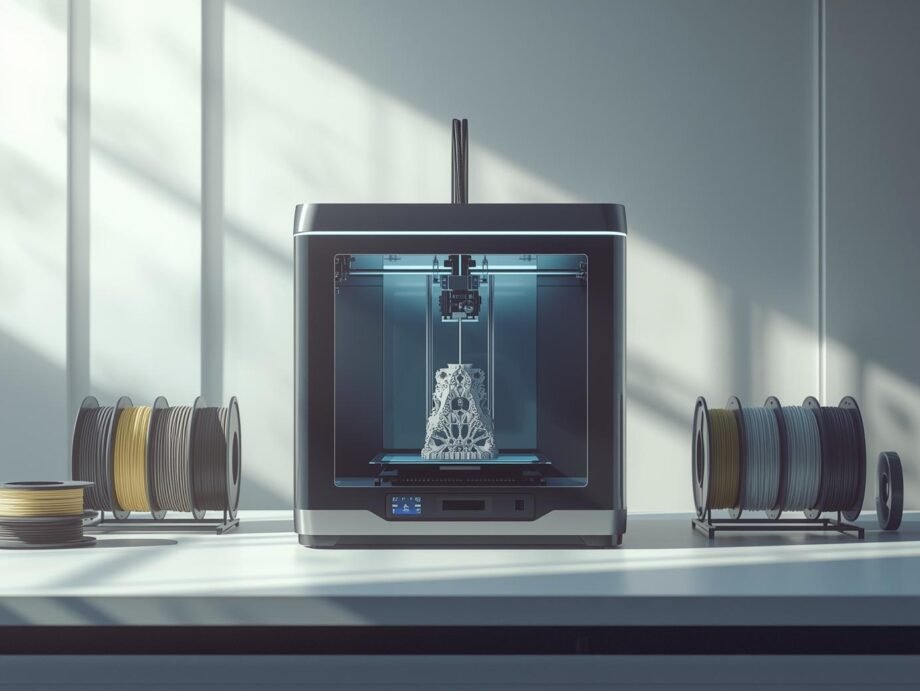

In 2025, something remarkable happened in the world of 3D printing.

For the first time, prosumer-grade 3D printers—machines designed for advanced hobbyists and small businesses—outsold industrial systems by unit volume.

This shift marks more than a manufacturing milestone—it signals the democratization of production, where creative professionals, footwear designers, and even sneaker startups can now achieve industrial-quality results from compact desktop machines.

At the heart of this boom are brands like Bambu Lab and Creality, whose accessible yet powerful printers are rewriting the economics of design and fabrication.

For the footwear world, it’s a breakthrough moment: the tools that once cost tens of thousands of dollars are now within reach of independent designers, local brands, and even serious hobbyists.

📊 The 2025 3D Printing Market by the Numbers

According to the latest 2025 3D Printing Market Report, the global industry is expanding rapidly—but not in the way most expected.

- Global Market Value: The market reached $22.4 billion in 2023, and is projected to exceed $80 billion by 2030.

- Category Breakdown:

- Entry-Level / Prosumer (<$2,500): +15% YoY, over 1 million units shipped in Q1 2025.

- Professional ($2,500–$20,000): Flat or slightly declining.

- Industrial (>$100,000): –14% YoY in unit shipments, with many buyers holding off on upgrades.

The takeaway: volume is migrating to prosumer devices, and that includes designers in the fashion, accessory, and footwear sectors.

For every enterprise losing ground, dozens of small studios are gaining it—powered by fast, precise, and affordable machines that fit on a desk.

⚙️ The Rise of the Prosumer Revolution

A prosumer 3D printer bridges the gap between maker-grade and professional hardware.

Priced between $3,000 and $10,000, these machines are fast, reliable, and capable of production-quality output—making them ideal for prototyping footwear components, molds, insoles, and design elements.

What’s driving adoption?

- Speed + Precision: CoreXY designs and enclosed chambers make it possible to print midsoles, lattice structures, and molds with micron-level accuracy.

- Material Flexibility: TPU, flexible resins, and nylon composites open up realistic footwear prototyping.

- Smart Automation: AI calibration, multi-material systems, and onboard monitoring reduce trial and error.

- Cost Accessibility: Desktop machines now deliver 80–90% of industrial performance at 10% of the cost.

In short: footwear innovation has been unshackled from the factory floor.

Designers can print wearable prototypes overnight, test new textures and cushioning systems, and iterate in real time—without outsourcing or long lead times.

🏠 The Decline of Industrial Dominance

Industrial 3D printers still dominate in total revenue, but not in momentum.

The 2025 3D printing market report shows enterprise systems losing ground as companies seek agility and affordability. Many traditional manufacturers are scaling down, while designers and independent brands are scaling up.

Why the drop?

- High capital costs: Six-figure machines are hard to justify when prosumer units achieve similar precision.

- Slow development cycles: Startups iterate in days; industrial providers move in quarters.

- Distributed manufacturing: Designers are producing locally or on demand, reducing the need for centralized factories.

In the footwear space, this means mass customization is finally viable—producing size-specific midsoles or personalized shoe components without minimum order quantities.

🚀 The Brands Powering the Boom

Bambu Lab: Speed and Precision for the Masses

No brand symbolizes the 2025 boom better than Bambu Lab. Its X1 Carbon and P1 Series printers combine CoreXY motion, enclosed chambers, and AMS (Automatic Material System) for seamless multi-color and multi-material printing.

Shipments grew 64% in Q1 2025, and adoption is especially strong among small manufacturers and designers producing custom parts and prototypes.

For footwear creators, Bambu’s blend of speed, temperature control, and dimensional accuracy is ideal for functional materials like TPU or flexible filaments used in soles and uppers.

Creality: The Global Volume Leader

Shenzhen-based Creality continues to lead in total sales volume, holding roughly 39% of global entry-level and prosumer shipments. Its Ender 3 V3 KE and CR-10 Smart Pro lines deliver reliable, low-cost production capabilities that appeal to both makers and small businesses.

Creality’s influence extends to footwear design studios experimenting with in-house prototyping—using 3D printing not just for parts, but for presentation-ready samples and even limited-run accessories.

Other Innovators to Watch

- Formlabs: With the Form 4, resin-based systems have entered production territory, suitable for midsoles, molds, and lattice test prints.

- Elegoo & FlashForge: Offering accessible resin and FDM hybrids for flexible prototyping.

- Prusa & Ultimaker: Trusted by educational institutions and design labs for open-source flexibility.

These brands are collectively reshaping the creative process—making 3D printing a design tool, not just a manufacturing method.

🔌 The Technology Behind the Prosumer Breakthrough

The line between desktop and industrial is blurring thanks to real technical leaps:

- CoreXY Architecture: Faster motion control allows larger footwear prototypes with smoother finishes.

- AI + Machine Vision: Smart calibration ensures dimensional accuracy across complex lattice patterns.

- Multi-Material Systems: Bambu’s AMS enables flexible + rigid part combinations in a single print—perfect for footwear prototypes combining structure and cushion.

- Flexible Material Compatibility: TPU, TPE, and nylon blends bring functional footwear printing within reach.

- Cloud & IoT Integration: Designers can monitor print farms remotely, scheduling multiple pairs or iterations overnight.

In essence, footwear designers now have access to tools that rival industrial prototyping labs, without the six-figure investment.

💼 Small Brands and Footwear Startups Are Winning Big

Across the global design landscape, small teams are doing big things with prosumer 3D printers.

- Boutique shoe designers are creating entire collections of 3D-printed uppers, soles, and modular accessories.

- Custom orthotic startups are using desktop resin systems to produce individualized insoles at scale.

- Micro-brands are launching sustainable, made-to-order footwear lines with minimal waste.

According to Ultimaker’s 2025 3D Printing Sentiment Index, 84% of businesses now use 3D printing for product development, and 38% produce end-use parts—a trend that includes small footwear and fashion tech companies.

The appeal is simple: creative freedom, reduced waste, and local control.

🔮 The Future: A New Era of Footwear Manufacturing

The prosumer boom is only beginning. Analysts expect continued double-digit growth through 2026, driven by AI-assisted design, robotics, and advanced materials.

In the footwear world, expect:

- AI-driven generative design for cushioning, traction, and ergonomics.

- Full automation of print farms for on-demand production.

- Circular materials—filaments and resins derived from recycled shoes and bioplastics.

- Direct-to-consumer fabrication models, where buyers customize, print, and receive footwear faster than traditional factory cycles.

As industrial players pivot toward software and materials, the future of footwear manufacturing will belong to decentralized creators—brands and studios using accessible hardware to produce what once required a factory.

🧩 Conclusion: The New Makers of Tomorrow’s Shoes

The 2025 3D printing boom isn’t just an industrial story—it’s a design revolution.

From hobbyists to global footwear startups, the prosumer era has unlocked a new balance of creativity, performance, and independence.

Machines like Bambu Lab’s X1 and Creality’s CR-10 are no longer just printers—they’re production tools for the next generation of footwear visionaries.

In this new landscape, the next iconic sneaker may not come from a factory in Asia.

It might come from a studio, a maker lab, or even a designer’s spare room—printed, assembled, and worn into the future.