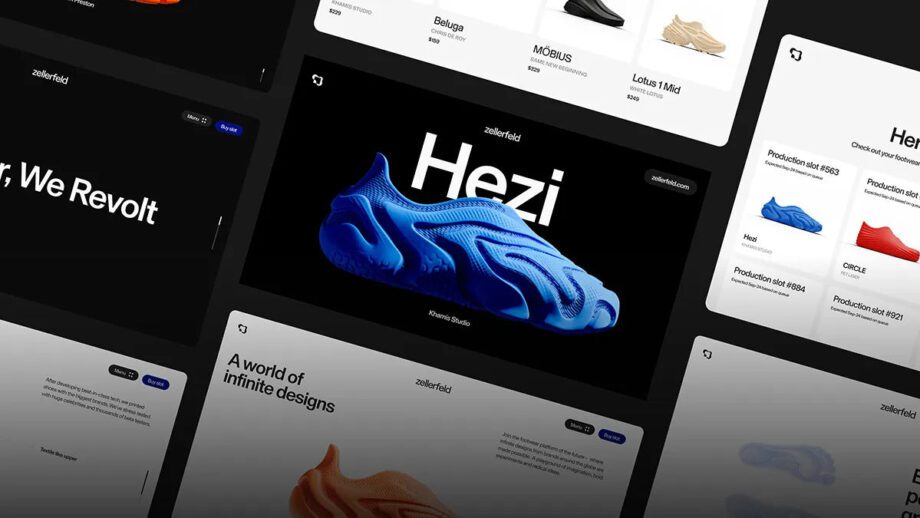

After more than a year since the launch of its beta version, Zellerfeld is now prepared for the next phase of its open platform. This platform allows consumers to browse and purchase a variety of 3D-printed shoe designs.

Earlier this week, the Hamburg, Germany-based 3D-printed footwear tech company made an exciting announcement. They have officially transitioned their platform out of beta and are now prepared to fully launch their innovative concept, which they are referring to as the “YouTube of Shoes.” This platform allows individuals from all walks of life to upload their shoe designs on Zellerfeld’s platform and have them brought to life.

Zellerfeld co-founder and CEO Cornelius Schmitt shared with FN in an interview that the launch follows the successful production of over 10,000 pairs of shoes from its beta program. These shoes featured designs from renowned brands such as Moncler, Chris Brown, KidSuper, and Heron Preston.

The insights gained from our beta program have been invaluable in refining our operational functions, including efficient production and shipping of large quantities of shoes, providing excellent customer support, and ensuring the perfect fit for our customers,” Schmitt shared. “We are excited to announce the launch of our revolutionary footwear platform, where individuals from all over the world can easily upload their own 3D models and make them available for purchase within a day.”

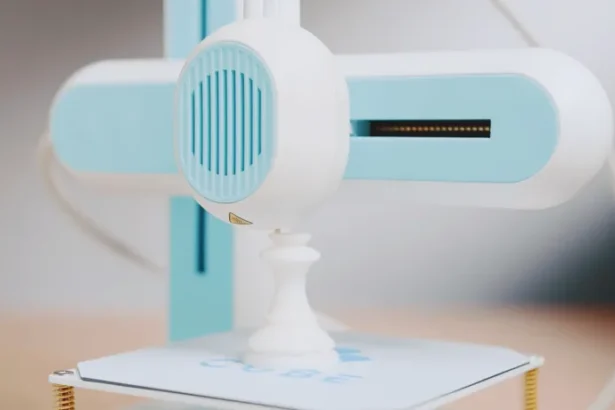

Photo courtesy by Zellerfeld.com

In this new program, Schmitt highlights the ability of designers and brands to quickly introduce fresh ideas to the market. At the same time, consumers have the opportunity to explore a wide and constantly growing selection of footwear. The CEO highlighted the platform’s goal of breaking down traditional financial and logistical barriers in the footwear industry. This enables real-time experimentation and product refinement. Thanks to Zellerfeld’s innovative design parameters and cutting-edge printing capabilities, development times that used to take 12 to 18 months can now be completed in just a matter of days.

“Picture a world where every designer, regardless of their resources, can bring their vision to life and connect with a global audience,” Schmitt expressed. Consumers are entering a new era where footwear innovation is becoming the standard rather than the exception. Let’s bring back the excitement of footwear after years of repetitive releases, superficial updates, and color changes. Our platform enables creators to push the limits of design, explore new ideas with confidence, and drive sustainable innovation. This is an incredibly important movement, and we are proud to be at the forefront, spearheading the fight against exploitative labor practices and antiquated production techniques. We invite brands to join us in driving this transformation.

Zellerfeld’s new platform is now live, featuring the integration of Zellerfeld Studio. This exciting addition provides designers with state-of-the-art tools to easily order samples and quickly bring their creations to market. In order to submit a design, creators are required to submit their plans to the company’s Discord platform. Automated systems will then verify the files and create Zellerfeld Studio accounts for designs that have been approved. These designs will be available on Zellerfeld.com, providing consumers with a new marketplace to shop for footwear.

So, what is the company’s revenue stream under this new business model? There are two clear methods. Zellerfeld is offering production slots to customers for $10 each, which may be of interest to consumers. After securing a slot, customers have the flexibility to include multiple styles in their order until the production batch starts. At that point, they will be billed for the remaining cost of the shoes, which will be shipped once they are ready. According to Schmitt, users will have the ability to reserve a spot in the production queue and ensure that they receive the desired printed shoes. They can also save their slot for future use or switch to different shoes based on what becomes available.

The CEO emphasized that the company’s focus on making it easier for consumers to get involved is also a strategic move to generate funds for expanding their production facility in Hamburg. This expansion will enable them to meet the growing demand and scale up their print farm.

Zellerfeld offers a fair profit split with each designer on the brand side, ensuring that they receive 40 percent of the sale after covering the cost of production, shipping, and other services provided.

“Everything we have accomplished leads up to this pivotal moment,” Schmitt stated. We have enhanced our technology and processes through partnerships with industry leaders to introduce a revolutionary open platform that transforms the world of footwear.” This is not just a regular launch; it is a complete revolution. We are determined to revolutionize the footwear industry and will not rest until we achieve our goal.