Many startups, fashion brands, original equipment manufacturers (OEMs) and large shoe companies are working on 3D printed shoes. I love the optimism and the fact that this could one day lead to millions of 3D printed shoes. However, I do think that there are lower hanging fruit that businesses in the industry can grab before issues related to 3D printed shoes are resolved.

Issues with 3D Printed Shoes

3D printing a whole shoe is a bit problematic. AM is traditionally bad at flexible and soft materials. Advances in silicone 3D printing notwithstanding, the industry has had problems making soft and flexible materials that last a long time in the field and can withstand continued stresses and use. Temperature resistance, chemical resistance, and the ability to withstand the wear and tear of the streets has been problematic.

Yeezy Supply 3D printed boots. Image courtesy of Zellerfeld

Additionally, while polymers are not great at breathability in general, the ones the 3D printing industry tends to use are very sweaty indeed. The sector has had a lot of progress with PA 11 for Multi Jet Fusion and TPU for material extrusion. Carbon has demonstrated progress in terms of quality and strength for photopolymer materials. However, on the whole, most 3D printed shoes are a sweaty affair. Also, the performance of lattice structures is difficult to predict and a nice looking lattice will often not bend in an organized way but collapse like wet spaghetti thrown at a wall. I’ve opined before that, if we want to 3D print the whole shoe, we should opt for collaboration with a weaving technology or something like Shima Seiki´s 3D knitting system to make the upper.

3D Printed Soles

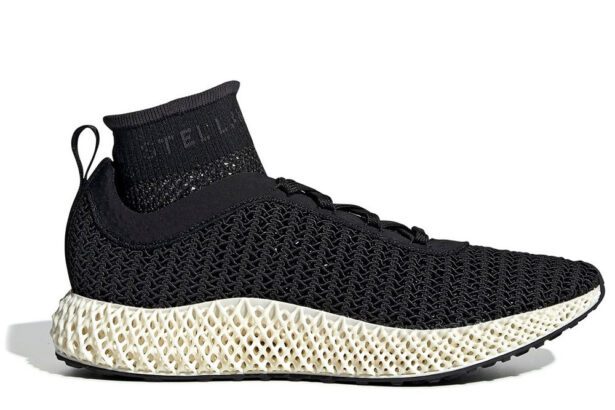

There are many advantages to 3D printing midsoles and soles. Additive manufacturing (AM) can make the shoe (or custom insoles based on a scan of your foot) your exact size. By trapping air, material extrusion can create custom air pockets to give you a comfort that is impossible with other techniques. At the voxel level 3D printing can offer dynamic insoles that are unique at every point, also something that you can not do with other technologies.

Image courtesy of adidas.

AM can produce locally close to the consumer and make shoes to order. It can fabricate with less waste and fewer materials. 3D printing can reduce pollution and CO2 emissions because the fewer materials means a single shoe can can be manufactured in a single place. 3D printing can create effects inside the sole to stop slippage, as well as unique lateral or forward motion patterns. AM can also be used to produce shoes more quickly, depending on market trends and without any stock. This means you could easily create one-offs or very unique designs to grab attention, find collectors and new markets.

3D Printed Orthotics and Specialty Shoes

I really like 3D printing as a technology for orthotics and other custom- or quasi-medical soles or shoes. SmarTech Analysis projecting it as part of a segment that will reach nearly $1 billion in revenues by 2030 in its “Medical Devices 2021: Market Opportunities for 3D Prosthetics, Orthotics and Audiology Devices” report.

I also like AM for specialized shoes, such as HP did with climbing shoes. I can really see a business case for 3D printed soles, especially in conjunction with companies or organizations that walk a lot (see FitMyFoot and Leisure Care). Imagine you could go to the US Army and tell them you could make all of their 480,000 personnel walk with greater comfort and feel more well rested. The same could be done with UPS, the NYPD, and other organizations. Construction companies, factory workers, and more could benefit, as would their employers if they got customized gradient insoles. That’s a wonderful business case.

3D Printed Sandals

3D printed shoes as is are too expensive and, in their current form, curiosities. However, in the long run the potential to upend the shoe business. By requiring less capital tied up in stock and creating less fashion risk while being quicker to market, 3D printing can disrupt the shoe business—if someone gets it right. But, this will take time. Until then, it’s possible to 3D print a perfectly viable 3D printed footwear product for the masses right now. We can 3D print sandals.

Using desktop material extrusion 3D printers, powder bed fusion equipment, and flexible vat polymerization resins, AM can already make fully functional 3D printed sandals. They’d be more expensive than regular sandals, but, we can make unique textures with wicking effects to engender comfort. Because they don’t enclose the foot, you don’t have the problems that the 3D printed shoe has. It won’t be sweaty as hell. Your feet won’t feel hot and uncomfortable. You won’t slip and slide around like crazy inside the shoe either.

It’s possible to customize the inside structure to a 3D scan, or even customize at the voxel level with a gradient sole. One could make the whole thing out of one 3D print out of one material. It would be cost-effective to make and require little labor. It would be a low structure, so a very cost effective 3D print.

People have been 3D printing slippers for years now. Asics made a recovery slipper, while this research team made a sensor sandal for diabetics. You can download a wide variety of flip flop files. Retraction Footwear attempted to sell 3D printed flip flops, but didn’t succeed. People tried to do a Kickstarter with Impact footwear as well but this didn’t work. Fused and Zellerfeld are developing slip-ons that are close to sandals.

However, still no one has really built a brand around a 3D printed slipper successfully. Most of the 3D printed efforts were simply not promoted well enough and didn’t reach a wide audience. Others looked horrible or were poorly made. Generally no one has seemed to make a good brand, a good idea and a good design come to life in the minds of many. This is a straightforward business opportunity but getting it right won’t be easy.

SOURCE: https://3dprint.com/299260/3d-print-flip-flops-not-shoes/