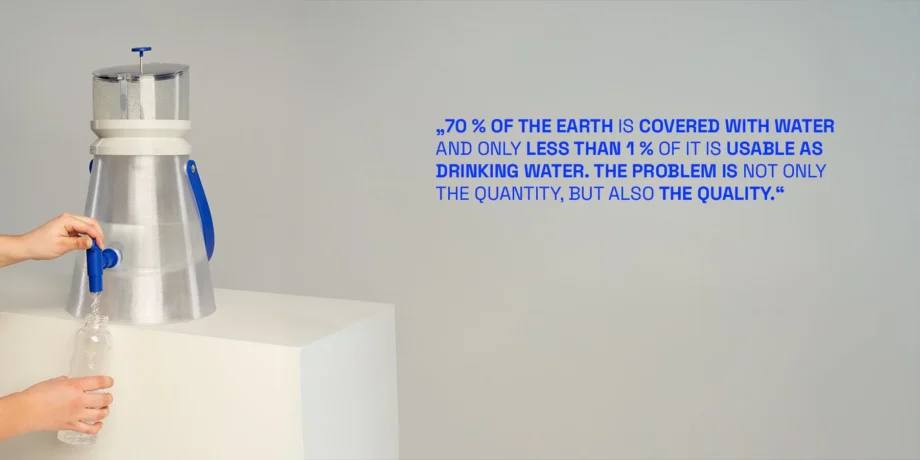

Access to clean drinking water is one of the most pressing global challenges of the 21st century. While billions live in water-scarce regions, a team of engineers has unveiled a 3D-printed device that can literally pull water from thin air—a breakthrough that could change the way communities, homes, and even disaster zones access safe water. Unlike futuristic concepts that remain in labs, this technology is not only affordable but also reproducible, opening the door for DIY enthusiasts, schools, and innovators to build their own versions.

How Does It Work?

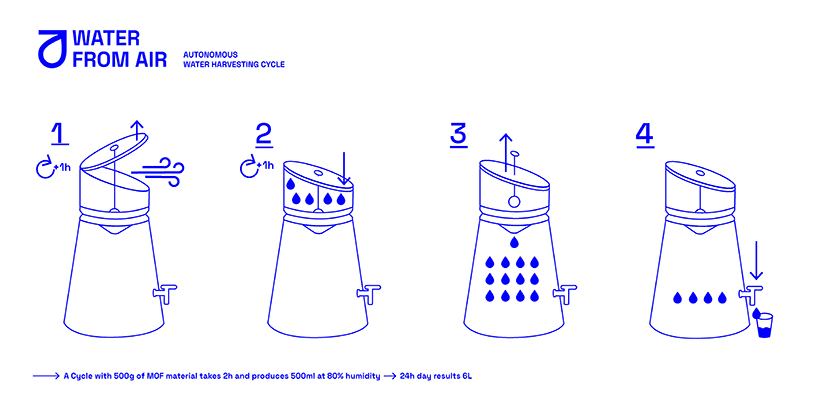

The device leverages hygroscopic materials—substances that naturally absorb moisture from the air. Think of how a packet of silica gel in a shoebox collects humidity, but on a far more advanced scale. Engineers 3D-printed a lattice structure coated with special salts and polymers that pull in water vapor, even from relatively dry environments. Once collected, a solar-powered heating system warms the material, releasing the trapped water vapor, which then condenses into drinkable liquid.

This cycle of absorption and release requires no external electricity grid, making it viable in off-grid or disaster-stricken areas.

The 3D-Printing Process

The team used additive manufacturing (3D printing) to prototype the structure, which is key to the device’s performance. Instead of a flat surface, the design uses a porous, sponge-like geometry that maximizes surface area for capturing vapor. According to the engineers:

- Material: Polymers infused with calcium chloride or other hygroscopic salts.

- Design: Lightweight lattice with repeating geometrical patterns for strength and efficiency.

- Size: Scalable; lab versions are small, but the design can be scaled up for households or villages.

The benefit of 3D printing is that anyone with a desktop printer and access to the right materials can potentially replicate the design. While commercial versions are being refined, DIY builders could adapt the concept with off-the-shelf parts.

Can You Build One Yourself?

Yes—at least in a simplified form. Based on publicly available details:

- Frame: 3D-print a porous structure using standard PLA or PETG filament. While not as effective as advanced polymers, these are accessible.

- Coating: Apply a hygroscopic salt coating, such as calcium chloride mixed with a polymer binder to help it stick.

- Condensation Chamber: Build a simple enclosure with transparent plastic or glass to trap solar heat.

- Collection Tray: Use food-safe plastic or stainless steel to gather condensed water.

This DIY model will not yield as much water as the engineered prototype, but it demonstrates the science and could inspire community-driven innovations.

Comparison With Other Water-Harvesting Technologies

This 3D-printed device stands out among existing water-harvesting approaches:

- Fog Nets: Already used in parts of Chile and Morocco, fog nets collect droplets from mist but require specific climates.

- Atmospheric Water Generators (AWGs): These work like dehumidifiers, cooling air to condense water, but they consume significant electricity.

- Solar Stills: Use evaporation and condensation to purify water, but are limited in scale and speed.

In contrast, the 3D-printed hygroscopic device is low-cost, solar-powered, and portable, bridging gaps where traditional technologies fall short.

Environmental and Societal Impact

The potential of this innovation is enormous:

- Disaster Relief: Imagine emergency kits containing portable water harvesters for survivors of earthquakes or floods.

- Rural Communities: Villages with no reliable infrastructure could harvest water daily without relying on expensive pipelines.

- Climate Resilience: As droughts intensify, localized water harvesting could reduce dependence on shrinking rivers and overdrawn aquifers.

Critically, the fact that the device can be fabricated via 3D printing means that it is not locked behind industrial supply chains. Communities can locally print parts, reducing costs and encouraging self-reliance.

The Road Ahead

While the current prototypes are promising, engineers are working on:

- Improving the efficiency of water capture in very arid conditions.

- Testing durability over months or years of use.

- Scaling the technology for community-level water supply.

If successful, this 3D-printed device could democratize access to clean water in ways never before possible.

FAQ

Q: How does the 3D-printed water harvester work?

It uses special moisture-absorbing materials combined with a 3D-printed structure that captures humidity and releases clean water when heated by sunlight.

Q: Can people build this device at home?

The concept is simple, but the exact materials (like advanced hydrogels and MOFs) are still under research. DIY versions may work in principle, but efficiency will be much lower.

Q: How is this different from dehumidifiers or fog nets?

Unlike traditional machines, it doesn’t need electricity and can function in dry climates. Compared to fog nets, it works even without visible mist.

Q: How much water can it produce?

Current prototypes can yield several liters of water per day depending on humidity and sunlight. Scaling up is a key focus for engineers.

Q: What is the potential impact of this technology?

It could provide clean water to communities without reliable access, especially in arid regions, disaster zones, or off-grid areas.

Final Thoughts

Water-from-air devices have long captured the imagination of scientists, but 3D printing has made it possible to build them cheaply, quickly, and at scale. For students, hobbyists, and communities alike, this is more than just an engineering marvel—it’s a practical solution that could redefine water security worldwide.

Sources & Further Reading

- mobile 3D printed device extracts drinking water directly from air — designboom, July 2025. Louisa Graupe & Julika Schwarz’s design details, materials, fabrication, and operation. Designboom

- A New 3D Printed Device is Capable of Transforming Air into Drinking Water — 3Dnatives, July 16 2025. Technical breakdown, MOF functionality, scalability, and design philosophy. 3Dnatives

- Engineers design mind-blowing 3D-printed device that can pull water from thin air: ‘A practical solution’ — The Cool Down, August 19 2025. Context on global water scarcity; device yield, accessibility, and intent. The Cool Down

- Atmospheric water generator — Wikipedia, August 2025. Tech context, comparative energy requirements, and global potential. Wikipedia

💡 Takeaway: The technology is real, reproducible, and scalable. With further refinement, it could be as common as solar panels—quietly pulling life-giving water out of the very air around us.