Introduction: Goodbye, Bland Purées

Roughly 8 percent of the world—about 590 million people—struggle to swallow safely.

Yet most dysphagia diets still revolve around beige purées and thickened drinks that look anything but appetizing.

A new open-access study in Nature‘s Scientific Reports changes that narrative. Researchers at Kyushu University and Cardiff University 3D-printed edible gels that “cook” in mid-air using radio waves or microwaves, creating beautiful, custom-textured foods in real time.

This article unpacks:

- Why texture matters for people with swallowing disorders

- How the Nature-featured team built a LEGO-based food printer

- The science of dialing firmness from soft to springy with the turn of a frequency knob

- What it all means for personalized nutrition, hospital meals, and even cultured meat

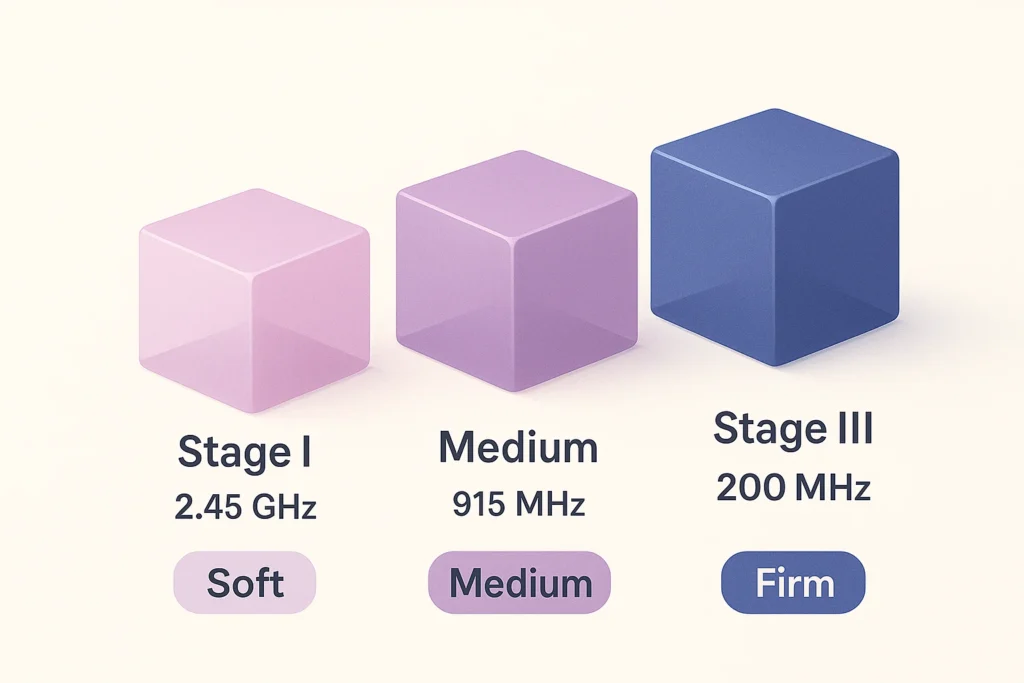

1. Dysphagia 101 — and the Texture Problem

- Safety first: Food that is too thin may infiltrate the airway; too sticky and it can cling to the throat.

- Japan’s gold-standard hardness scale:

- Stage I — 2.5 × 10³–1 × 10⁴ N·m⁻²

- Stage II — 1 × 10³–1.5 × 10⁴ N·m⁻²

- Stage III — 3 × 10²–2 × 10⁴ N·m⁻²

- User experience gap: Conventional blenderized foods meet safety specs but often flop on flavor, aroma, and plate appeal.

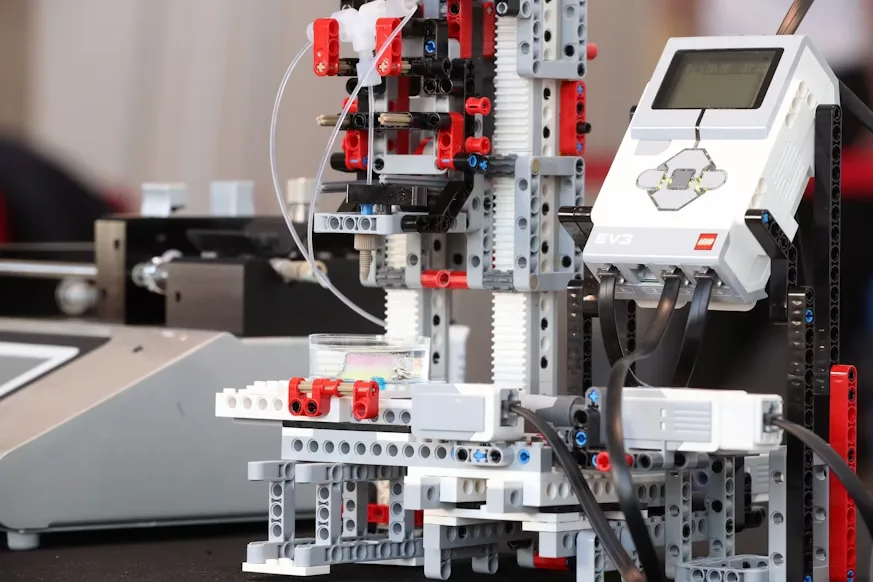

2. The Nature Study at a Glance

| What | Detail |

|---|---|

| Paper | “Radiofrequency and microwave 3D bioprinting of emulsion gel for dysphagia diets,” Scientific Reports (July 2025) |

| Printer | LEGO Mindstorms EV3 frame + syringe pump |

| Heating | 200 MHz RF or 915 / 2.45 GHz MW cavities |

| Output | Egg‑white emulsion gels that meet Stage I–III criteria |

Key takeaway? Texture became a tunable parameter—like choosing font weight in a design file.

3. Inside the Edible “Bio‑Ink”

- Proteins: Ovalbumin & ovotransferrin (egg white)

- Stabilizers: Xanthan gum (0.5 wt %), MgCl₂ (2 wt %)

- Emulsifier: Tween 80

- Flavor & nutrition carrier: Canola oil (40 %)

When heated, the proteins cross‑link into a viscoelastic network while oil droplets lock in flavor and fat‑soluble vitamins. The formula already satisfies Japan’s dysphagia guidelines before printing.

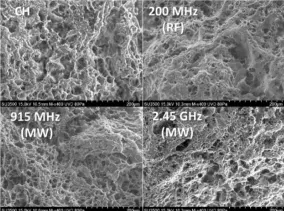

4. RF vs. Microwave: Dial‑A‑Texture

| Frequency | Result | Why it Happens |

|---|---|---|

| 200 MHz RF | 4× harder than water‑bath gels; +40 % water retention → Stage III | RF energizes Mg²⁺ ions → dense fibrous network |

| 915 MHz MW | Medium firmness; Stage II | Partial protein aggregation |

| 2.45 GHz MW | Soft, sticky, Stage I; 2× adhesiveness of RF gel | Primarily heats water dipoles → looser mesh |

All versions passed official safety standards, proving frequency alone can tailor mouthfeel.

5. How the LEGO Food Printer Works

- Syringe pump pushes bio‑ink at 100–1000 µL min⁻¹.

- Ink snakes through an RF or MW cavity heater, monitored by an optical fiber until it hits ~70 °C.

- Semi‑gel filament exits the nozzle and layers up as the LEGO X‑Y platform moves.

- Flow = 500 µL min⁻¹ and 10 W power gave the cleanest prints in testing.

6. Real‑World Impact

- Hospitals & elder‑care: On‑demand meals that match each patient’s swallowing strength and flavor preference.

- Sports & wellness: Layer vitamins or electrolytes into designer gels for post‑workout recovery.

- Cultured meat & alt‑protein: Same heating trick could set plant or lab‑grown proteins into steak‑like textures.

- Market pull: The medical‑nutrition sector alone is projected to hit US $51 billion by 2028.

7. Hurdles to Clear

- Scale‑up: Syringe printers are slow; industrial RF tunnels might solve throughput.

- Regulation: FDA/EFSA pathways for 3D‑printed medical foods are still evolving.

- Sensory tests: Flavor perception in RF‑set gels vs. microwave‑set gels needs human trials.

Conclusion: Texture at the Touch of a Frequency Dial

Tsubaki and colleagues have handed food technologists a new toolbox: print, cook, and customize—all in a single step. As 3D food printers migrate from labs to commercial kitchens, don’t be surprised if the next menu item for seniors or ICU patients is a perfectly shaped, flavor‑rich gel “printed” minutes before serving.

Credits

Research by Shuntaro Tsubaki, Ayane Ide, Daniel R. Slocombe, Oliver Castell, Ibrahim Maamoun & Noriyuki Igura. Scientific Reports, Vol 15, Article 25023 (2025). Open‑access on Nature.com under CC BY‑NC‑ND 4.0.