Pair artificial intelligence and algorithmic software with 3D printing and you have the potential to easily and economically personalize all types of products.

Over the recent decades of globalization, brands have offered products that meet the needs of as many people as possible worldwide with very generic product designs. (Think of Ikea furniture or H&M clothing.)

And yet, there’s a higher perceived value for products that are custom-made or even products that we make ourselves. (Think of the handmade cup you or your child made that you still cherish years later.)

What if we could combine custom-made and mass-produced?

Using computational design, the concept of personalization can be achieved on a mass scale. Let’s look at an example.

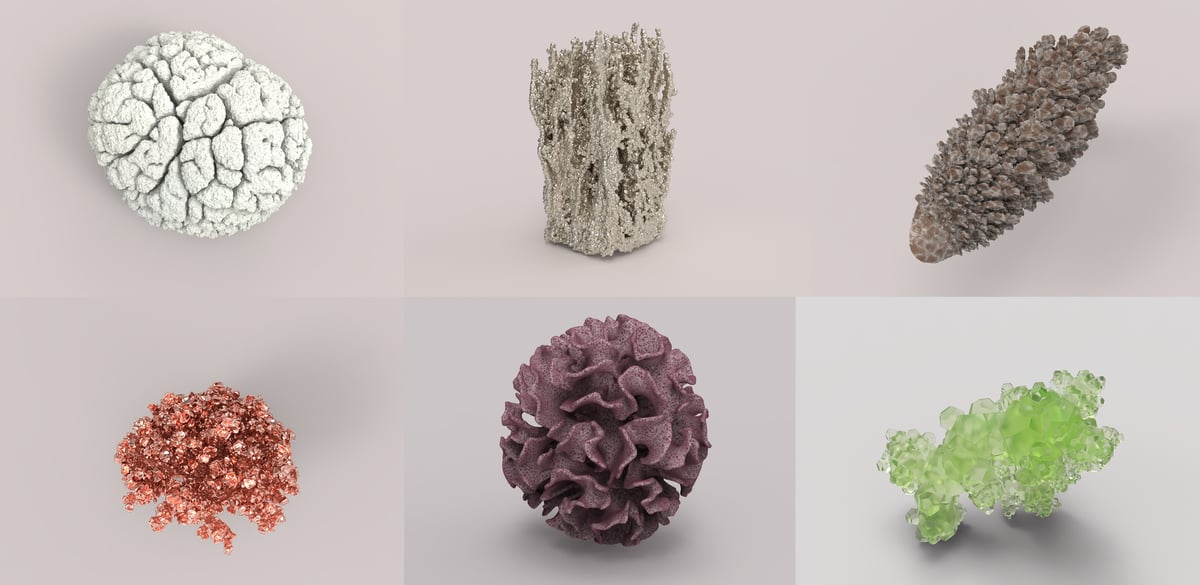

This show project was produced using AI prompts starting with the concept of bubbles (Source: Nik Lee)

The Bubble Shoe Concept

Kids love blowing bubbles and wearing fun shoes. Imagine the appeal of enabling customers to design and order a unique pair of custom-fit bubble-motif shoes online like the ones shown above.

First, they’d scan the foot with a simple smartphone app so the shoe is made to the correct size. Following this, the child blows through a straw aimed at the PC’s microphone to create a unique bubble design on the surface of the shoes. The bubbles grow and move around as the blowing noise is registered. Once the child is happy with the design, the shoe design model is sent to a mass 3D print farm.

Computational design software would make this concept possible. Let’s take a closer look at what exactly this technology is.

What is Computational Design?

Computational design is a computer-aided design (CAD) method that uses a combination of algorithms and parameters to automatically compute a product’s structure.

It’s not artificial intelligence (AI) in that the software doesn’t make choices or learn, but computational design can leverage AI techniques and tools, such as generative algorithms, evolutionary optimization, and machine learning, to enhance the design process and create more efficient, innovative, and bespoke solutions.

With computation design, a model is produced by adding numerical values to predefined parameters. The designer does not draw or apply shapes. Unlike a traditional static design, a computational design is fluid and dynamic, meaning that it can be continuously altered by inputting new data. Each new piece of data can affect all the other pieces of data by establishing various relationships between the parameters.

We already see this in practice. Take a look at the 3D printed orthopedic brace company ActiveArmor. By using computational design and a platform by the software company Twikit, patient data, including anatomical sizes, type of injury, and movement restrictions as prescribed by a doctor, are input to generate the design of a fully customized brace. A much faster process than designing by hand for an individual.

Computational design is an umbrella term that encompasses several design processes, including parametric design, algorithmic design, generative design, and topography optimization. Although the methods within computational design blend into each other, they can be grouped into three main categories:

- Parametric design refers to when parameters are linked together into groups or nodes. When one value is changed, it automatically changes the other related values. This way, a design can be calculated quickly within predefined boundaries, such as maintaining the dimensions needed for manufacture.

- Algorithmic design is a step beyond this. Constraints are put into place, then complex software algorithms are used to generate the design. Imagine you are changing the shape of a building, when you change the shape, the algorithm will automatically change the panel design and layout on the building’s facade.

- Generative design is a step even further into what could be considered AI design. In this case you first define the boundaries, such as the outer rim of a bicycle wheel, then the inner boundary, which in this case is the axle. You then define the load requirements and the intended material type. The generative software will bridge the two areas with a range of possible design outcomes to choose from based on the strongest shape and using the minimal amount of material.

- Topology optimization is in the same category as generative design but it’s not the same. With topography optimization, you also define the volume. The software then computes the material that can be removed from this volume. Both methods can be controlled in different ways, however, the actual structure is dictated by the software algorithms.

Techniques used for computational design implementation can produce very complex forms, often mimicking the process of trial and error found in nature.

Historically these designs were hard or impossible to produce, given the limitations of traditional manufacturing techniques. But with the advancement of additive manufacturing, it is now possible to produce complex and unique structures with high-quality surface finishes at a mass scale. It opens up huge scope and new opportunities for computational product design for consumer goods, such as consumer electronics, fashion, homeware, and furniture.

Common Uses of Computational Design

Today, computational design techniques are commonly used in manufacturing and in many consumer products. These products benefit from the capabilities of parametric modeling, generative design, simulation, and other computational tools.

In robotics, automotive, and aerospace applications, computation design is used to reduce part count, increase strength-to-weight ratios, and improve thermal conductivity, among other benefits. A lighter part reduces energy consumption and is, therefore, cheaper when in use.

In sporting goods, equipment such as helmets are designed using computational tools to enhance performance by optimizing impact absorption based on sport and customized to the athlete’s head shape and size.

There are many use cases for computational design within medical applications, too. Both internally as bone replacements and external prosthetics and fracture treatment. In all these cases, it is hugely beneficial when the size and shape of the body part can drive the design.

At my own company, DesignFAM, which is officially launching towards the end of the year, we’ll focus on the computational design of consumer products for additive manufacturing.

One project we are currently working on uses precision engineering algorithms to produce bike components. Instead of having a solid metal part, a lightweight lattice structure is used to reduce the weight. The thickness of the lattice structure is increased or decreased using software depending on the stress requirements needed in a particular area.

Bike design is a good example of a functionally driven, mechanical product where visual design is also important. Many of these field-driven lattice structures offer a new and quite visually appealing look to the product design.

If you’re interested in seeing these parts built into a complete bike, we’ll be showcasing it at the Formnext Expo in Frankfurt, Germany, in November.

Another project we are working on together with 3D printer maker BigRep is a concept study (pictured above) to see what furniture would look like if we let the computer define the shape. We use topography optimization software from nTop to input parameters, such as the weight the furniture would need to hold, to find the optimized shape that uses the minimum amount of material. By using this engineering approach, we can create unique and unusual forms that are both visually interesting and functionally accurate.

Theoretically, a bike frame can be designed to fit the requirements of an individual person. It will use the minimum material to cater to the maximum force generated by the user. Therefore a bike designed for a lighter rider will need less material, resulting in a lighter bike, at a lower cost, with less waste.

We’re seeing something similar in the new Posedla bicycle saddle. Customers sit in the Smiling Butt Kit and take pictures of the imprint that’s uploaded to an online configurator. An algorithm then uses scan data and customer data to design the saddle stiffness, shape, and pressure zones.

Form, Function & Texture

The following images show a study into how algorithms could create unique patterns and textures achieved by programming the software to simulate growth over time. These simulations create a digital replication of patterns found in nature. What I like about this approach is that every product could be subtly different, similar to the subtle uniqueness of leather or wood.

One of the problems with products manufactured from man-made materials like plastics is that they look very generic. People tend to feel a closer connection to things that are unique to them. This is part of the reason natural materials look and feel so good. Materials such as marble have huge irregularities — every part has an original pattern and is therefore unique — this is perceived as a value to using the material.

When 3D printing an object designed with algorithms, every part can be different, so why not push this further and make the textures also different?

What Software is Used for Computational Design?

There’s not really one software that is most popular for designing for computational implementation. It’s essential to have a wide understanding of all parametric and procedural software, ranging from mechanical design platforms like Fusion 360 to Houdini, which is software used for animation and game design.

Computational Design & Additive Manufacturing

Additive manufacturing has led to the biggest change in design since CAD was introduced in the 1980s. It gives designers the opportunity to completely rethink the design approach. Instead of having production and material limitations to design around, we can focus on designing products that seamlessly fit the body and the environment around us. The outcome of this has and will continue to result in a massive change to the look and feel of products.

Computational implementation for physical product design goes hand in hand with 3D printing. It’s the only way to design individually unique products in a fast and efficient way for mass production. 3D printers can print dozens or hundreds of unique parts all at once directly from the digital file with no molds or tools, which is something no other manufacturing technology can.

Computational design techniques can generate very complex parts. Traditional manufacturing, such as injection molding, casting, and CNC milling, is extremely limited in its ability to make complex internal channels, for example. In most cases, your digital design would have to split into several smaller entities for traditional manufacturing and then assembled, or you’d be forced to modify the design to make it suitable for a technology, such as machining.

About the author: Nik Lee is a creative professional with international experience in product design and innovation. His new company DesignFAM will be launching towards the end of 2023, with a focus on environmentally conscious design for 3D printing.

SOURCE: https://all3dp.com/1/computational-design-in-3d-printing-for-mass-customization/