In a breakthrough that challenges long-standing limitations in materials science and physics, researchers from Northwestern University and Fermilab have developed a method for 3D printing monocrystalline high-temperature superconductors. This innovation merges additive manufacturing with seeded crystal growth, enabling the creation of complex geometries with record-setting performance, including a nearly 180-fold increase in current-carrying capacity over previously printed versions.

As Dr. Dingchang Zhang, lead author of the Nature Communications study, puts it: “We’ve shown that it’s possible to fabricate complex 3D shapes and convert them into single crystals that retain their geometry and superconducting properties.”

This article explores the materials, science, and engineering that made this advancement possible—and what it means for the future of superconducting technology.

What Is YBCO—and Why Is It So Hard to Print?

Yttrium Barium Copper Oxide (YBCO) is a prominent high-temperature superconductor (HTS) that operates at around 90 K, making it viable with liquid nitrogen cooling—a more affordable alternative to liquid helium. However, YBCO poses unique fabrication challenges:

- It’s brittle, making it difficult to shape

- It requires a precisely aligned crystal structure

- It must have accurate oxygen content to maintain superconductivity

A key obstacle is the presence of grain boundaries in polycrystalline YBCO. These misalignments disrupt electron flow, drastically reducing the critical current density (Jc). In contrast, monocrystalline YBCO—free of grain boundaries—can carry higher currents and trap strong magnetic fields, which is essential for high-performance superconducting applications.

Why Traditional Methods Weren’t Enough

Historically, creating monocrystalline YBCO required top-seeded melt growth (TSMG), a process restricted to simple geometries like pellets or slabs. While researchers could 3D print YBCO using ceramic-based additive methods, these parts always ended up polycrystalline, and therefore, electrically underperforming.

Until this study, no method combined complex 3D printing with monocrystalline performance—a gap that Northwestern and Fermilab have now bridged.

Step One: Robocasting the Superconductor

The process begins with direct ink writing (DIW), also known as robocasting.

How it works:

- A custom ink made of Y₂O₃, BaCO₃, CuO, and a PLGA polymer binder is extruded through a fine nozzle

- Intricate 3D shapes like toroidal coils, mesh lattices, and even a miniature paper airplane are printed

- The printed “green body” is then sintered at around 1000°C in an oxygen-rich environment, transforming it into polycrystalline YBCO

While this method enables precise geometries, the resulting material is still polycrystalline—and lacks optimal superconducting properties. That’s where seeded melt growth comes in.

Step Two: Seeded Melt Growth—Turning Ceramic into Crystal

In the second stage, the polycrystalline structure is transformed into a single crystal through a highly controlled thermal process:

- A NdBCO seed crystal is placed on the printed component

- The part is heated above 1030°C to induce partial melting

- It is then cooled at a slow rate of 0.5 K/hour, allowing the crystal lattice to grow uniformly from the seed

Why it works:

The addition of Y₂BaCuO₅ (Y211) particles in the ink serves as a scaffold, helping the structure retain its shape during the melt phase. This ensures the geometry remains intact as the seed crystal propagates through the material.

Validated by science:

- X-ray diffraction (XRD) confirmed single-crystal alignment

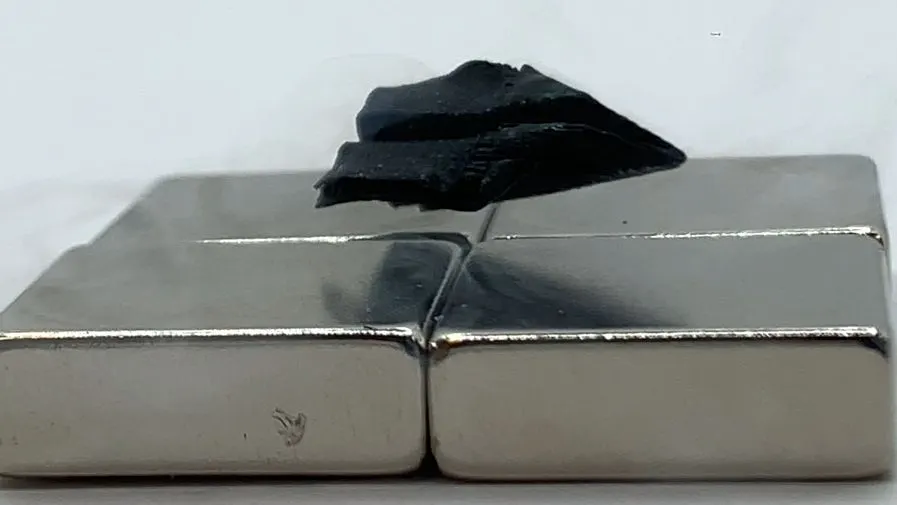

- Levitation tests demonstrated strong superconducting properties, including the Meissner effect

Performance Results: Breaking New Ground

This two-step method resulted in exceptional superconducting performance:

- Critical temperature (Tc): ~88–89.5 K

- Critical current density (Jc) at 77K: ~20,000 A/cm² (compared to ~300 A/cm² for polycrystalline YBCO)

- Jc at 10K: ~930,000 A/cm² (vs. ~5,200 A/cm²)

Demonstrations included:

- A 3D-printed paper airplane levitating above magnets

- A printed YBCO coil trapping a magnetic field for over 1,000 seconds

Minor microcracks due to oxygen annealing were observed but can be mitigated with silver alloying or improved cooling techniques.

Where This Leads: Practical Applications and Future Potential

The implications of this breakthrough extend across multiple industries:

Particle Accelerators & High-Field Magnets

- Custom superconducting magnets tailored for Fermilab’s particle beamlines

- Next-gen undulators for generating X-rays and gamma rays in synchrotrons

Quantum Computing & RF Systems

- High-temperature RF cavities for more efficient particle accelerators

- Superconducting resonators for dark matter research and quantum sensing

Medical & Energy Sectors

- MRI/NMR coils with enhanced performance and custom shapes

- Magnetic shielding, energy storage systems, and HTS current leads

Beyond YBCO

- The method could be adapted for Bi-based, Hg-based, or iron-based superconductors

- Potential to revolutionize piezoelectrics, thermoelectrics, and photovoltaic devices

Meet the Team Behind the Innovation

This project represents the power of interdisciplinary collaboration:

- Cristian Boffo (Fermilab): Initiated the project and led magnet-related R&D

- Prof. David Dunand (Northwestern): Expert in metallurgy and additive manufacturing

- Dr. Dingchang Zhang: Lead researcher who executed and refined the two-step process

Funded through Fermilab’s Laboratory Directed Research and Development (LDRD) program, the work was supported by Northwestern’s Materials Research Center, Cornell University, and industrial partners.

“This new technology will enable magnet designs that were previously unimaginable.” — Dr. Cristian Boffo

Conclusion: Redefining the Possible

This marks the first successful demonstration of:

- 3D printing a complex YBCO shape

- Converting it into a monocrystalline superconductor

- Achieving top-tier superconducting properties rivaling bulk-grown crystals

This isn’t just a materials breakthrough—it’s a new paradigm in superconducting design.

“The faster particles may in fact unlock new discoveries for physicists,” says Prof. Dunand. “And this is only the beginning.”

FAQs

Yes. It is now possible to 3D print a monocrystalline high-temperature superconductor like YBCO using a two-step process involving robocasting and seeded melt growth.

A crystal-growing technique where a seed crystal guides the solidification of a melted material, producing a uniform single crystal.

A form of direct ink writing (DIW) used to 3D print ceramic materials. Ideal for creating complex shapes with brittle compounds like YBCO.

Help Us Share the Breakthrough

Know someone working in materials science, quantum computing, or accelerator technology?

Share this article and help spread the word about the future of 3D-printed superconductors.

Sources: Nature Communications (2025), Fermilab News, McCormick School of Engineering, 3D Printing Industry