The 3D printing shoe industry has been making a few extreme headways, as several manufacturers test with 3D revealed orthotics and midsoles. In its report, “3D-Printed Footwear 2020-2030, an Analysis of the Market Potential of 3D Printing withinside the Footwear Industry”, SmarTech Analysis initiatives 3D printing in shoes to generate over the US $4.2 billion in annual sales in 2025.

To without a doubt make an effect, however, more than just the midsoles needs to be printed. The soft uppers have now no longer be as smooth to address with 3D printing. For the maximum part, additive production (AM) is extra of a hard-materials, instead of gentle-materials, era. For this reason, 3D printing has located its manner into style in an ungainly manner, in general thru excessive idea, plastic portions that might warfare to make it into patron wares.

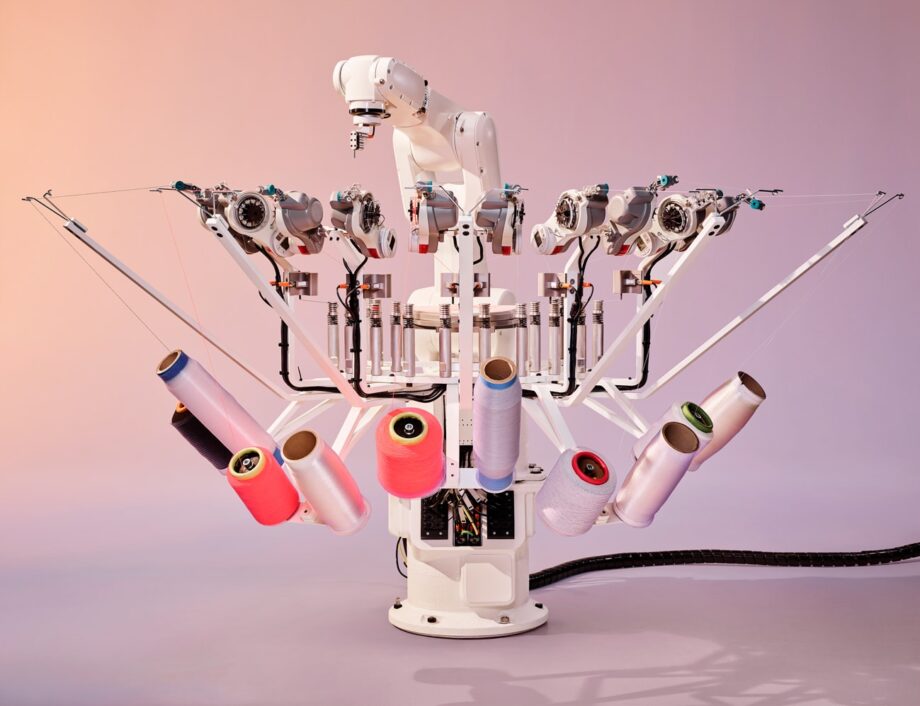

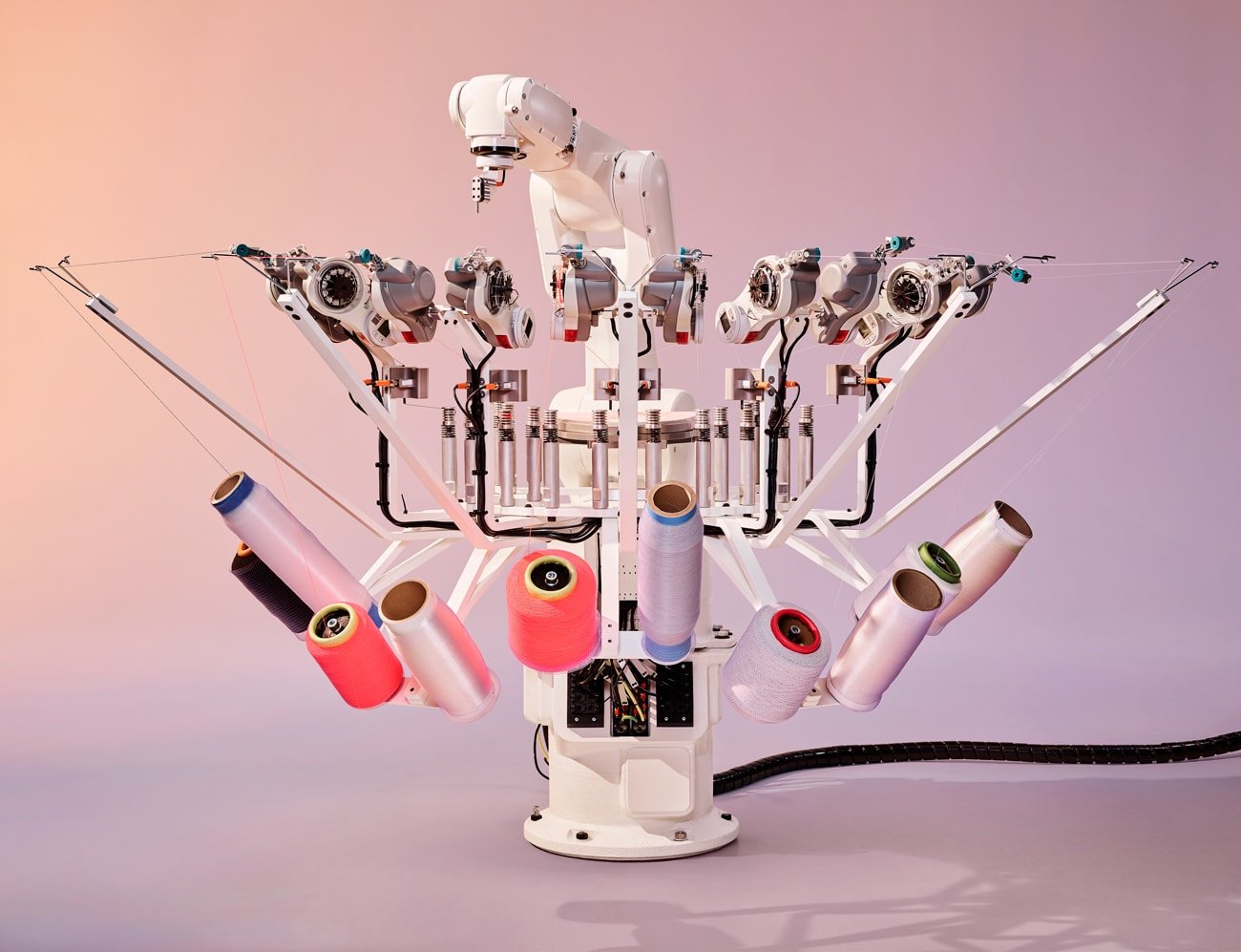

One principal producer that appears centered on tackling those boundaries is Adidas, which appears to have made the maximum development in phrases of liberating patron merchandise with 3D-revealed features. The brand’s Futurecraft line has visible some of 3D revealed midsoles hit digital cabinets during the last numerous years and the modern-day pair of footwear withinside the series consists of gentle uppers made the usage of a self-sufficient weaving robotic.

The FUTURECRAFT STRUNG is a proof-of-idea sneaker that becomes made with the aid of using a custom-constructed robotic that threads color-coded yarn throughout a 3D-revealed midsole. While the crimson strings are supposed to be stiffer and more potent to maintain the wearer’s heel in the area and supplying a long-lasting toe-field and midfoot, the yellow string is softer and upload flexibility to the forefoot of the shoe. The threads are woven in a programmed manner, with every one positioned precisely in which they’re designed to go—a piece like 3D printing.

Adidas ambitions to have the product withinside the marketplace with the aid of using past due 2021 or early 2022, centered in the direction of street runners with speeds of 5 meters consistent with second. If the corporation is capable of delivering, it’s going to have made essential strides in the direction of some of the essential goals, particularly lowering the waste and hard work related to the intake of footwear.

Automating the manufacturing of shoe production thru 3D printing and robot sewing may want to affect those problems with the aid of using lowering its dependence on underpaid hard work (that can instead be addressed with the aid of using spending fewer budget on athlete contracts and govt compensation) and lowering the quantity of fabric used to make footwear.

Adidas can be triumphing the race in 3D revealed shoes, doubtlessly ramping up its Speed Factories that use Carbon’s 3D printing era to fabricate midsoles. Though the opposition is steep, like New Balance, Under Armour, Nike and others have experimented with confined releases of footwear with 3D revealed parts. 3DShoes.com is looking forward to the day when there will be no waste of materials because of 3D Printing and changes have been shown for years on our www.Twitter.com/3dshoes social media feed. Voxel8 has even advanced a way for generating shoe uppers with 3D printing. However, none of the people are triumphing in the race towards the bigger issues of social and financial inequality and ecological collapse. We love footwear but we also hope that it will not destroy the ecology because of mass production.

#Shoes #3DShoes #3DPrintedShoes #Footwear #3DPrintedFootwear #3DPrinting #3DPrinted #3dprinter #3dprint #3dprints #Fashion #3DShoe

Original Article: https://3dprint.com/274027/adidas-adds-automated-weaving-robot-to-shoe-3d-printing-tech/