Brooks is continuing its partnership with HP with the launch of a new running sneaker using 3D printing technology.

Called the Exhilarate-BL shoe, the new sneaker model is part of the footwear brand’s BlueLine Lab program and was “specifically designed” for Brooks Run Club loyalty members.

Engineered in partnership with HP, the Exhilarate-BL running shoe features “3DNA,” a 3D-printed midsole technology that aims to deliver a bouncy feel that propels the wearer forward with ease. According to HP, the shoes deliver higher energy return on midsole production than 90 percent of market alternatives and fewer materials used.

Nikhil Jain, director of footwear product line management and BlueLine at Brooks, said in a statement that using HP’s 3D printing technology has allowed the company’s design team to “fine-tune” elements of the midsole right down to the millimeter in ways that “wouldn’t have otherwise been possible.”

“As a brand rooted in the science that every individual has a unique motion path, we’re just scratching the surface in terms of how we can change the underfoot experience and use 3D printing to deliver a premium, performance run experience with the potential for greater optimization,” Jain said.

At the same time, Brooks has been able to do so more sustainably by using less materials during production. “As a brand, we are focused on doing our part to ensure the shoes that we are building take a lot less energy and virgin material to manufacture,” Jain added. “And from a sustainability perspective we are learning how 3D printing can help us on that journey.”

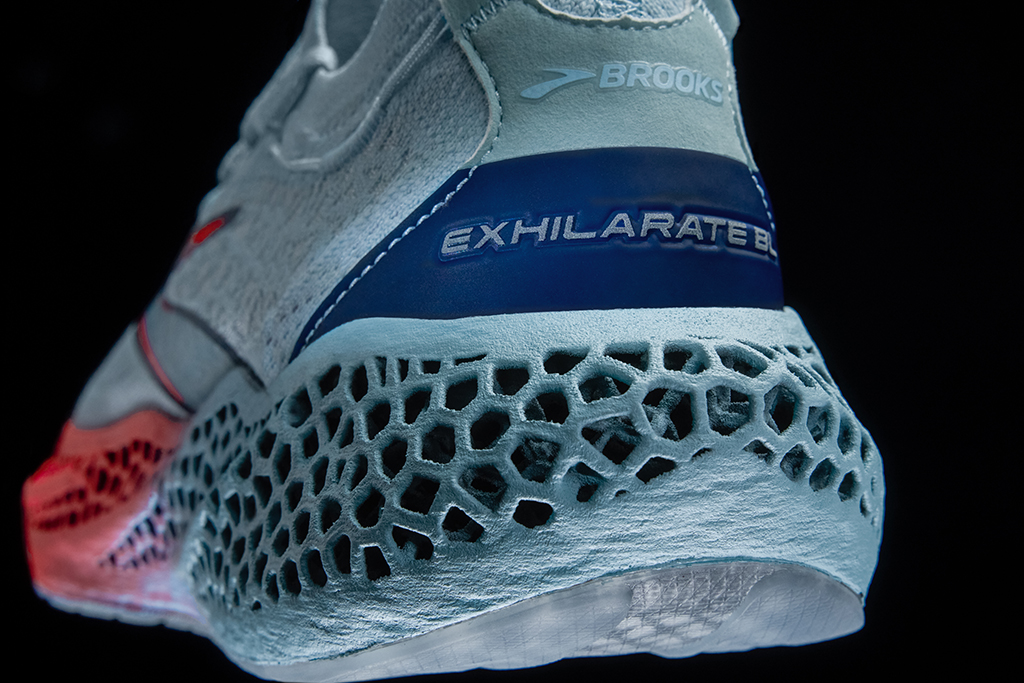

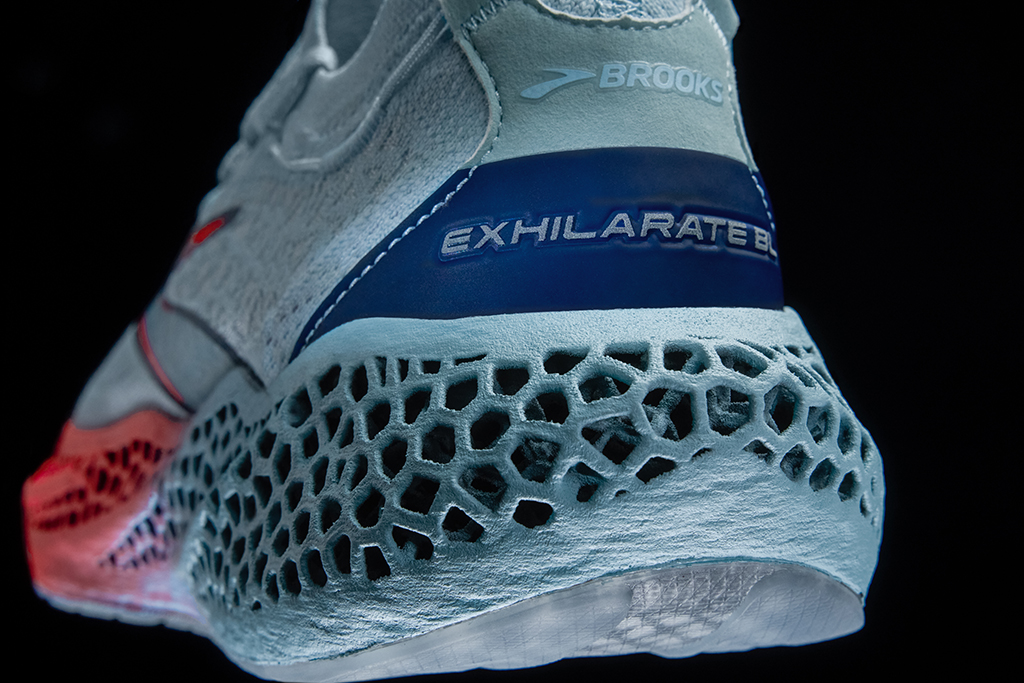

A look at the new Brooks Exhilarate-BL running shoe. COURTESY IMAGE

A look at the new Brooks Exhilarate-BL running shoe. COURTESY IMAGE

Brooks is continuing its partnership with HP with the launch of a new running sneaker using 3D printing technology.

Called the Exhilarate-BL shoe, the new sneaker model is part of the footwear brand’s BlueLine Lab program and was “specifically designed” for Brooks Run Club loyalty members.

Engineered in partnership with HP, the Exhilarate-BL running shoe features “3DNA,” a 3D-printed midsole technology that aims to deliver a bouncy feel that propels the wearer forward with ease. According to HP, the shoes deliver higher energy return on midsole production than 90 percent of market alternatives and fewer materials used.

Nikhil Jain, director of footwear product line management and BlueLine at Brooks, said in a statement that using HP’s 3D printing technology has allowed the company’s design team to “fine-tune” elements of the midsole right down to the millimeter in ways that “wouldn’t have otherwise been possible.”

“As a brand rooted in the science that every individual has a unique motion path, we’re just scratching the surface in terms of how we can change the underfoot experience and use 3D printing to deliver a premium, performance run experience with the potential for greater optimization,” Jain said.

At the same time, Brooks has been able to do so more sustainably by using less materials during production. “As a brand, we are focused on doing our part to ensure the shoes that we are building take a lot less energy and virgin material to manufacture,” Jain added. “And from a sustainability perspective we are learning how 3D printing can help us on that journey.”

For those interested in grabbing a pair of the new sneakers, they may just have to wait. Only a limited number of Exhilarate-BL pairs will be released as part of a “test and learn” program to select Brooks Wear Testers and Brooks Run Club loyalty members, the company said.

This isn’t the first time Brooks has teamed up with HP. In 2018, the two companies announced the launch of the Genesys shoe, which was customized to each buyer through 3D foot scanning technology.

At the time, HP used its FitStation technology to capture a 3D scan of the wearer’s foot. The system went a step further by taking into consideration other valuable points of data including gait analysis and foot pressure.