The world of additive manufacturing just took a major leap forward with the introduction of Carbon’s EPU Pro Platform. Designed for the next generation of elastomeric applications, this revolutionary family of resins promises high performance, usability, and sustainability. Let’s dive into what makes EPU Pro a game-changer.

What is the Carbon EPU Pro Platform?

Overview of EPU Pro

EPU Pro is a single-part, dual-cure elastomeric resin system specifically engineered for additive manufacturing. It offers a versatile range of mechanical responses, making it ideal for creating intricate latticed products and durable end-use parts.

Key Features of EPU Pro

- A wide durometer range (50A–90A) for flexibility in stiffness.

- Incorporates foaming agents to enhance resolution and haptics.

- Longer pot life for extended usability.

- Solvent-free cleaning compatibility and reduced material waste.

High Performance of EPU Pro

Wide Range of Stiffness Options

EPU Pro provides exceptional versatility, with durometers ranging from soft and flexible (50A) to firm and durable (90A). This flexibility allows manufacturers to create products tailored to specific performance needs.

Enhanced Mechanical Properties

Parts created with EPU Pro are stronger across the durometer spectrum. This improvement enables manufacturers to print delicate geometries, larger parts, and innovative designs with superior structural integrity.

Ease of Use in Manufacturing

Single-Part, Dual-Cure System

Unlike traditional two-part resin systems, EPU Pro simplifies the process with a single-part formula. This eliminates the need for complex mixing, reducing labor and equipment costs while enhancing usability.

Reduced Material Waste

EPU Pro’s extended pot life ensures minimal waste, and unused resin can be easily reused. This makes it a cost-effective and eco-friendly solution for manufacturers.

Sustainability and Eco-Friendly Design

Reusable Resin for Reduced Waste

By enabling the reuse of uncured resin, EPU Pro significantly reduces material waste. This not only cuts costs but also aligns with sustainability goals.

Solvent-Free Cleaning Compatibility

EPU Pro parts can be cleaned without solvents, making the process safer for workers and the environment. Additionally, cured parts can be reprocessed through melt-processing, contributing to circular manufacturing practices.

Innovative Design Capabilities

Unlocking New Geometries

EPU Pro resins offer enhanced printability, enabling designers to create complex, curved, and latticed structures with greater precision. These advancements open up new possibilities for innovative product designs.

Unique Haptic Experiences

From silky smooth to suede-like finishes, EPU Pro resins can be tuned to deliver a variety of tactile qualities. This versatility adds a distinctive touch to end-use products, enhancing user experience.

Application Areas for EPU Pro

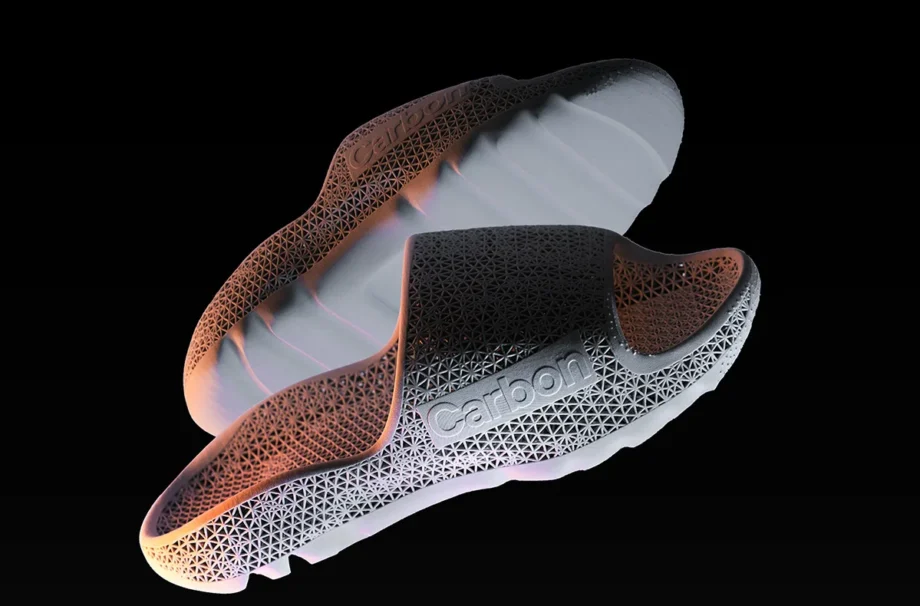

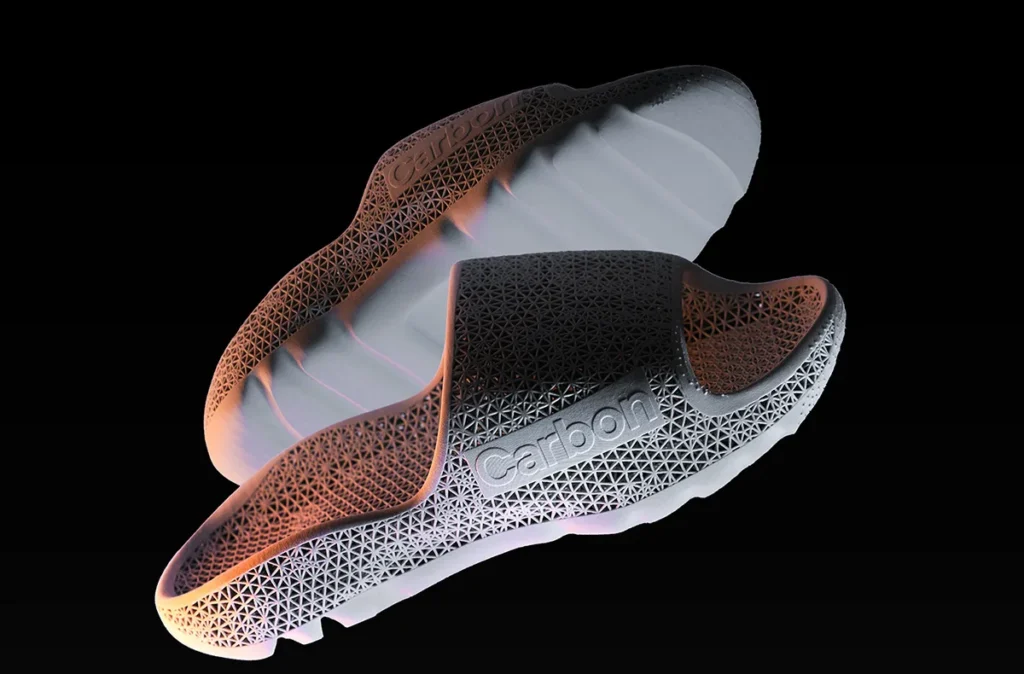

Footwear Innovation

EPU Pro’s flexibility and design capabilities are perfect for lightweight, high-performance footwear. It enables advanced cushioning, durability, and breathability, combined with an attractive matte finish.

Comfort and Performance Seating

From soft cushioning to firm support, EPU Pro materials can achieve a wide range of mechanical responses. This versatility enhances seating designs for better weight distribution, airflow, and overall comfort.

Grips and Handles

With the ability to create curved, breathable, and soft-touch designs, EPU Pro is ideal for grips and handles. It enhances user comfort while offering durable, aesthetically pleasing solutions.

Comparison with Other Carbon Elastomers

EPU 45 vs. EPU 46 vs. EPU Pro

- EPU 45: Energy-damping properties.

- EPU 46: Bio-derived, energy-returning elastomer.

- EPU Pro: Combines high performance, versatility, and usability in a single-part system.

Advantages of EPU Pro

EPU Pro builds on the strengths of its predecessors while simplifying processes and broadening design possibilities. Its unique blend of performance, sustainability, and ease of use sets it apart.

How EPU Pro Supports Product Development Goals

Tuning Mechanical Properties

EPU Pro allows manufacturers to fine-tune stiffness, energy absorption, and return, ensuring products meet exact performance requirements.

Customization for Aesthetics and Functionality

From tactile qualities to visual finishes, EPU Pro offers unparalleled customization options. This ensures products stand out in both form and function.

The Future of Elastomeric Resins

Expanding Use Cases

EPU Pro’s versatility paves the way for new applications across industries, including automotive, healthcare, and consumer goods.

Next Steps in Additive Manufacturing

As Carbon continues to innovate, the EPU Pro Platform sets a high standard for elastomeric materials, driving the evolution of additive manufacturing.

Why Choose Carbon’s EPU Pro Platform?

Performance and Reliability

EPU Pro delivers exceptional mechanical performance, ensuring reliability in even the most demanding applications.

Versatility in Applications

With its wide range of properties and design capabilities, EPU Pro is a flexible solution for diverse manufacturing needs.

Conclusion

Carbon’s EPU Pro Platform is more than just an upgrade—it’s a leap forward in elastomeric resins. By combining high performance, ease of use, and sustainability, EPU Pro unlocks new possibilities for additive manufacturing. Whether you’re designing innovative footwear, ergonomic seating, or advanced grips, EPU Pro offers the tools to bring your vision to life.

FAQs

1. What are the primary benefits of the EPU Pro Platform?

EPU Pro offers high performance, versatility, reduced waste, and ease of use, making it ideal for innovative manufacturing applications.

2. How does EPU Pro compare to other Carbon elastomers?

EPU Pro simplifies processes with its single-part system and offers a wider range of mechanical properties compared to EPU 45 and EPU 46.

3. Can EPU Pro be used in high-volume manufacturing?

Yes, its ease of use, long pot life, and reduced waste make EPU Pro suitable for high-volume production.

4. What industries can benefit most from EPU Pro?

Industries like footwear, automotive, healthcare, and consumer goods can leverage EPU Pro’s versatility and performance.

5. How does EPU Pro align with sustainability goals?

EPU Pro supports sustainability through reduced resin waste, solvent-free cleaning, and compatibility with circular manufacturing processes.