From 3D Printing to Smart Fashion

3D printing has already reshaped the future of footwear. From Adidas’ 4DFWD midsoles, engineered for energy return, to Zellerfeld’s fully 3D-printed sneakers, additive manufacturing continues to redefine how shoes are designed, customized, and produced.

Now, the next leap could be footwear that responds to its surroundings. Scientists have developed a 3D-printable photochromic material that reacts to light, changes color, and even performs basic logic operations — without electronics.

In a recent study published in Nature’s Light: Science & Applications, researchers revealed how light-responsive polymers can act as miniature “processors,” paving the way for materials that think. For fashion and footwear designers, this opens the door to adaptive, color-changing, and energy-efficient 3D-printed shoes.

This article explores how the technology works, why it matters, and how it could revolutionize the way we create and wear fashion.

The Science Behind Light-Responsive 3D Printing

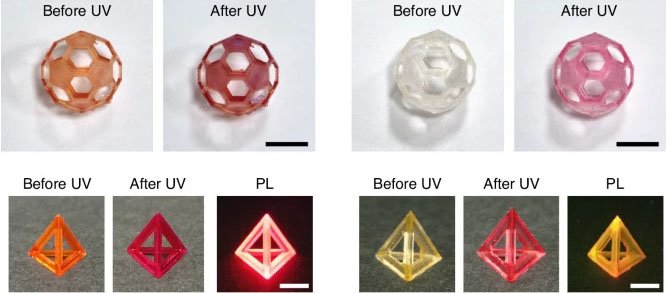

A groundbreaking study titled “All-optical processors by 3D printable photochromic materials” (DOI: 10.1038/s41377-025-01974-z) introduces a new class of photochromic materials — compounds that change color when exposed to UV or visible light.

Using spiropyran and diarylethene molecules embedded in a 3D-printable polymer matrix, researchers created a material that could reversibly switch colors, store light-based data, and perform simple logical operations similar to a computer processor — but without any electronic components.

The team achieved stable performance over 12 months, maintaining functionality through over 100 light–dark cycles with no degradation. This stability highlights the potential for long-lasting, intelligent materials that can be integrated into real-world applications.

This innovation goes beyond structure — it represents 3D-printed materials that interact with their environment, marking a major step toward functional, self-responsive fashion.

What “Thinking” Materials Mean for Footwear Design

Imagine stepping into sunlight and watching your sneakers shift from white to violet, or walking indoors to reveal hidden geometric patterns. That’s the potential of photochromic 3D printing applied to footwear.

But it’s not just about visual appeal — it’s functional innovation:

- UV indicators could alert wearers to excessive sun exposure.

- Wear tracking systems could gradually change color as the sole ages.

- Performance shoes might visually react to light, heat, or motion zones.

Because these photochromic polymers are 3D-printable, designers can integrate light-reactive elements directly into the shoe’s structure — no coatings or surface dyes needed. The intelligence lives within the material itself.

This seamless fusion of smart design and organic responsiveness blurs the line between technology and craftsmanship, expanding what’s possible in the next generation of responsive fashion.

Beyond Aesthetics: Energy-Efficient and Sustainable Fashion Tech

Most “smart shoes” today rely on sensors, chips, and batteries, which add weight, limit comfort, and contribute to electronic waste.

Photochromic 3D printing offers a battery-free, energy-efficient alternative.

These materials operate using just 10–30 mJ/cm² of light energy — significantly lower than traditional phase-change materials. Their self-sustaining light reaction means no electricity or power source is needed.

This innovation aligns with the growing demand for sustainable fashion tech — eco-friendly solutions that combine functionality and environmental responsibility.

Major brands are already exploring this space:

- Adidas experiments with bio-based TPU for 3D-printed components.

- Reebok’s Cotton + Corn project promotes plant-based materials.

- Balenciaga has tested recyclable 3D-printed prototypes.

By integrating photochromic polymers, designers can merge sustainability with intelligence, creating smart, zero-power shoes that react naturally to the environment.

How 3D Printing Makes It Possible

The key to this innovation lies in additive manufacturing — specifically Digital Light Processing (DLP) 3D printing, a method known for high-resolution precision.

This process allows photochromic polymers to be shaped into complex geometries ideal for footwear applications, such as:

- Intricate midsole lattices with localized light reactions

- Textile-like uppers that reveal patterns dynamically

- Decorative elements that change hue under different lighting conditions

3D printing also brings core benefits that align with sustainable fashion manufacturing:

- Reduced waste: On-demand production eliminates excess inventory.

- Customization: Unique, user-specific responses and patterns.

- Efficiency: Direct integration of smart materials without post-processing.

As global brands like Adidas, Balenciaga, and Under Armour push the boundaries of 3D-printed design, photochromic polymers could become the next big material innovation in footwear production.

The Future: Programmable Fashion That Reacts

The concept of programmable fashion — where materials are engineered to think and react — is quickly moving from fiction to reality.

Future applications could include:

- Running shoes that brighten as you move faster

- Jackets that shift color in low light for visibility

- Accessories that shimmer or change tone based on mood or environment

Instead of embedding electronic circuits, designers may soon program material behavior at the molecular level.

This approach transforms personalization from digital wearables into organic, responsive matter.

As scientists, fashion designers, and 3D-printing pioneers collaborate, we’re entering an era of interactive, expressive, and sustainable fashion — where design and intelligence coexist seamlessly.

Challenges Ahead Before These Shoes Hit the Market

While the potential is exciting, several challenges remain before color-changing, light-reactive shoes reach consumers:

- Response time: Current materials react in 30–70 seconds — too slow for instant visual feedback.

- Durability: Real-world wear testing under stress, moisture, and UV exposure is still needed.

- Manufacturing scale: Integrating photochromic polymers into fabric-like or large-volume footwear designs remains complex.

- Safety and comfort: Ensuring skin compatibility and consistent performance is crucial for consumer adoption.

However, as 3D printing materials evolve and optical chemistry advances, these barriers are expected to fade — just as early challenges in flexible resins and TPU midsoles were eventually solved.

A Light-Activated Leap for 3D-Printed Fashion

The fusion of 3D printing and photochromic materials represents a pivotal step toward smart, sustainable fashion — one where light itself becomes a design tool.

By harnessing the power of light, researchers have created energy-free, customizable, and interactive materials that could redefine how we experience footwear and apparel.

Tomorrow’s 3D-printed shoes may not just fit your feet — they may think with light.

💡 Sidebar: How Photochromic Materials Work

Photochromic compounds change molecular structure under specific wavelengths of light.

When exposed to UV light, they absorb energy and shift color; when the light source is removed, they revert to their original transparent or base color — enabling reversible, color-changing effects ideal for fashion and design.

Stay ahead of the future of footwear.

👉 Follow 3DShoes.com for the latest breakthroughs in 3D printing, smart materials, and sustainable shoe innovation.

Your next pair of sneakers might be smarter — and brighter — than you think.