The future of fashion is evolving, and sustainability is at the forefront of that transformation. Unspun, a fashion-tech company renowned for its innovative 3D weaving technology, Vega, has teamed up with Decathlon Pulse, the investment arm of global sportswear giant Decathlon. This powerful collaboration aims to revolutionize sustainable apparel manufacturing across Europe, with an eye on reducing waste, lowering carbon emissions, and rethinking how clothes are produced and consumed.

In this article, we’ll dive into the details of this partnership, explore Unspun’s cutting-edge technology, and discuss why this collaboration is set to reshape the fashion industry across Europe.

A Major Partnership: Decathlon Pulse and Unspun

In a move that signals a huge step forward for sustainable fashion, Unspun has secured both investment and a long-term offtake agreement with Decathlon Pulse. This partnership, which is set to run through 2030, will see Unspun’s 3D weaving technology, Vega, expand to multiple European brands under Decathlon’s umbrella.

So, why is this partnership so important? It’s about more than just innovation; it’s about creating a new way of producing garments—one that is local, low-waste, and efficient. For Decathlon, this means a chance to lead the charge in sustainability while continuing to offer high-performance sportswear to consumers. For Unspun, it’s an opportunity to scale their technology and make a significant environmental impact.

Unspun’s Vega Technology: The Future of Apparel Manufacturing

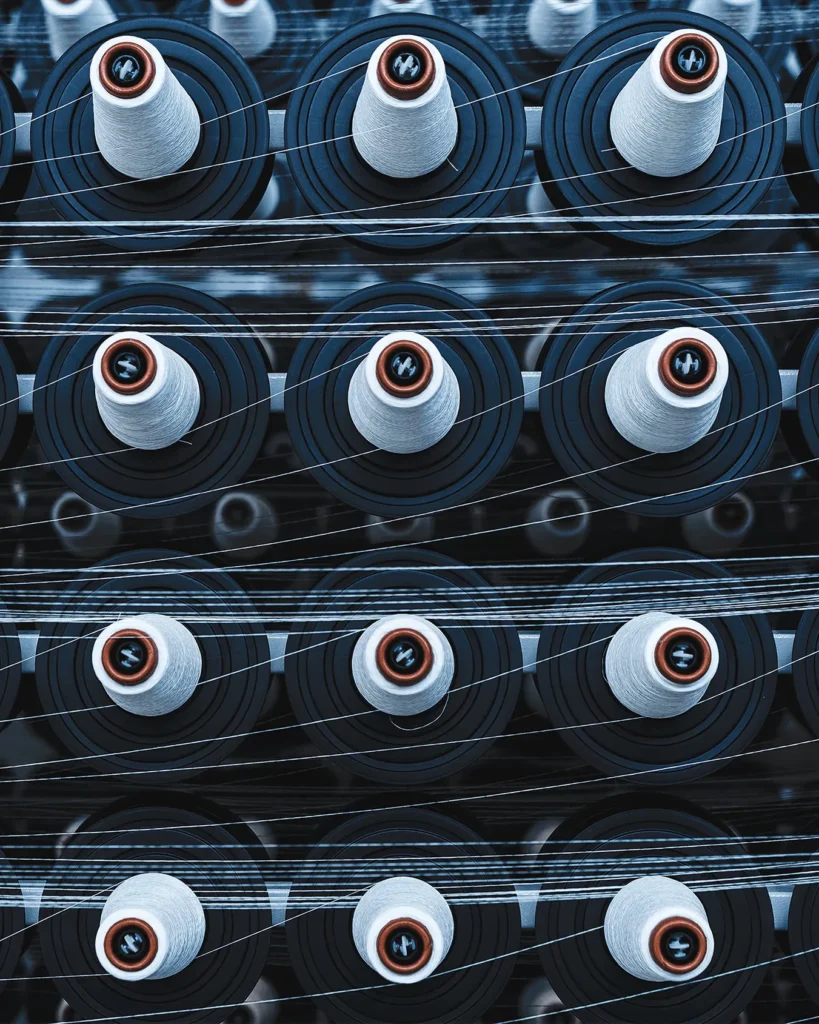

At the heart of this partnership is Unspun’s Vega technology, a groundbreaking 3D weaving process. Unlike traditional methods that cut fabric from large rolls, leaving behind scraps and wasted material, Vega weaves garments directly from yarn into semi-finished products. This method eliminates much of the waste associated with garment manufacturing, reducing both material loss and the environmental burden.

Vega technology doesn’t just minimize waste; it also allows for on-demand, customizable production. Imagine being able to order clothing tailored specifically to your measurements, created locally and sustainably, without the need for mass production and excess inventory. This is exactly what Unspun aims to achieve with their 3D weaving approach.

Decathlon Pulse’s Commitment to Sustainability

Decathlon has long been committed to sustainability, and their partnership with Unspun is another bold step in that direction. By investing in and supporting the expansion of Vega technology across Europe, Decathlon Pulse is helping to transform the way clothing is made.

Franck Vigo, CEO of Decathlon Pulse, expressed his enthusiasm for the collaboration, noting: “This partnership will enable Decathlon to reduce waste within the manufacturing process and strengthen our commitment to sustainability. By leveraging the potential of 3D weaving, we are working to revolutionize the garment manufacturing process and offer consumers customized, recyclable, and locally-produced products.”

The benefits of this partnership go beyond just reducing waste; it also aligns with Decathlon’s broader goals of offering high-quality, eco-friendly products that meet the needs of modern consumers. By embracing 3D weaving, Decathlon is setting a new standard for the industry, paving the way for other brands to follow.

A Shift Toward Local, Low-Waste Production

One of the key aspects of the Unspun-Decathlon Pulse collaboration is the focus on local, low-waste production. Rather than relying on massive, centralized factories that churn out thousands of units at once, Vega technology enables more localized production. This approach not only reduces transportation emissions but also allows for better inventory management.

Local production means less stock sitting in warehouses, fewer unsold items being discarded, and a drastic reduction in the industry’s overall carbon footprint. It’s a model that tackles some of the biggest challenges in fashion today—overproduction, excessive inventory, and the environmental toll of shipping goods around the world.

Meeting the EU’s Waste Framework Directive

The timing of this partnership is crucial, especially with the European Union’s upcoming Waste Framework Directive. This directive will introduce stricter regulations on waste management, including measures that directly impact the fashion industry, such as reducing unsold inventory and limiting overproduction.

Unspun’s Vega technology is perfectly positioned to help European brands meet these new requirements. By enabling on-demand production and better inventory control, the technology offers a practical solution to the overproduction problem that has plagued the fashion world for decades. Brands using Vega technology will not only comply with the EU’s new regulations but will also gain a competitive edge in a marketplace that increasingly values sustainability.

Tackling the Global Waste Problem

The global waste crisis is one of the most pressing environmental challenges of our time. Experts predict that global waste will increase by 70% by 2050 if current trends continue, and the fashion industry is a significant contributor to this problem.

Unspun’s collaboration with Decathlon Pulse represents a direct response to this issue. By reducing waste at every stage of the production process, from raw materials to finished garments, Vega technology offers a pathway toward a more sustainable future. As more brands adopt this technology, the potential for positive environmental impact is enormous.

Unspun’s Track Record of Innovation

Unspun is no stranger to innovation. The company has already earned accolades for its work in sustainable fashion, including being named to prestigious lists such as Time magazine’s “America’s Top Greentech Companies 2024” and Newsweek’s “Climate Change Innovators.”

This recognition highlights Unspun’s role as a leader in the movement toward more sustainable fashion. Their technology not only promises to reduce waste but also addresses key concerns around carbon emissions, water usage, and the environmental impact of traditional manufacturing methods.

Looking Ahead: The Future of Fashion

The Unspun-Decathlon Pulse partnership is just one example of how the fashion industry is beginning to embrace a more sustainable future. As consumer demand for eco-friendly products grows, companies are being pushed to rethink their production methods, and technology like Vega is leading the way.

With the backing of Decathlon Pulse, Unspun is poised to make a significant impact in Europe and beyond. Their shared commitment to sustainability is a blueprint for how the fashion industry can evolve, focusing on reducing waste, producing locally, and offering high-quality products that are both customizable and eco-friendly.

Conclusion: A Milestone in Sustainable Fashion

The partnership between Unspun and Decathlon Pulse marks a significant milestone in the journey toward sustainable fashion. By combining Unspun’s innovative 3D weaving technology with Decathlon’s vast reach and commitment to sustainability, this collaboration is set to transform apparel manufacturing across Europe.

With Vega technology at the helm, the future of fashion is looking greener, more efficient, and more localized than ever before. As the industry continues to grapple with the environmental challenges it faces, partnerships like this one will be key in driving meaningful change.

FAQs

1. What is Unspun’s Vega technology?

Unspun’s Vega technology is a 3D weaving process that creates garments directly from yarn, minimizing waste and enabling customizable, on-demand production.

2. How does this partnership benefit Decathlon?

The partnership allows Decathlon to reduce waste in their manufacturing process, produce locally, and offer more sustainable products to consumers.

3. Why is local production important?

Local production reduces transportation emissions, improves inventory management, and cuts down on unsold stock, all of which contribute to a more sustainable fashion industry.

4. How does Vega technology help with sustainability?

Vega technology reduces waste by weaving garments directly from yarn, eliminates the need for mass production, and supports on-demand, customizable clothing that minimizes excess inventory.

5. What impact will the EU’s Waste Framework Directive have on the fashion industry?

The EU’s Waste Framework Directive will impose stricter regulations on waste management, pushing the fashion industry to reduce overproduction and unsold inventory, making technologies like Vega even more crucial.