At 3dshoes.com, we focus on the practical engineering advances that shape manufacturing. A recent development from ETH Zurich presents a tangible step forward in metal 3D printing technology. A student team has built a functional rotational 3D printer capable of processing multiple metals in a single, seamless print job. This article breaks down how this wire-based process works and its realistic potential for creating advanced components.

How the ETH Zurich Multi-Metal 3D Printing Process Works

The innovation, developed by Master’s students Carlo D’Ambrosio and Luca Di Stasio, tackles a common industrial problem: effectively joining dissimilar metals without creating weak points.

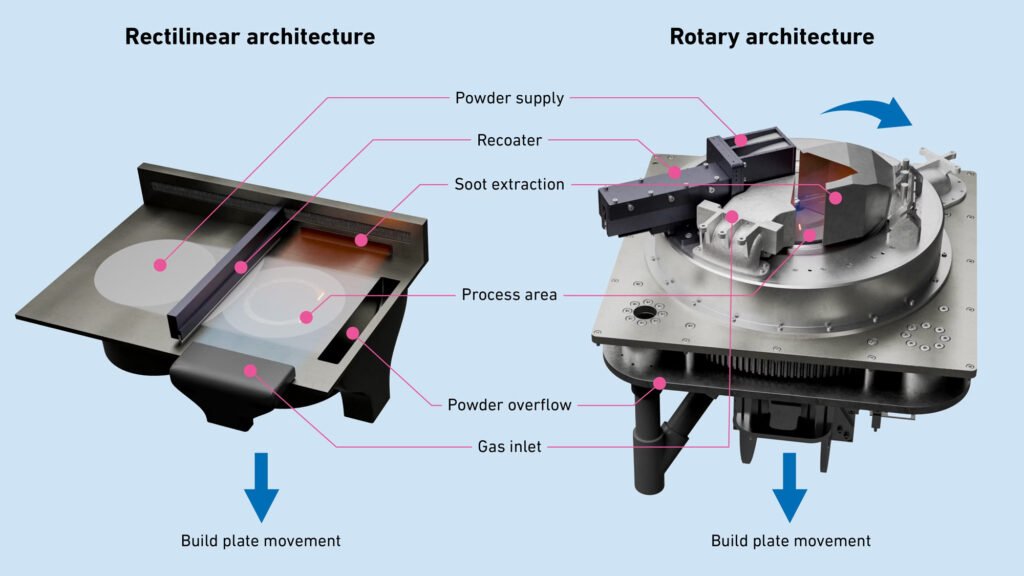

Their system is a modification of Direct Energy Deposition (DED) printing. The key is a rotating print head that holds spools of different metal wires, such as steel and copper. A laser melts the tip of the actively fed wire, depositing material layer by layer. The head rotates on-axis, switching the metal wire feed in milliseconds. This allows for the creation of objects with both sharp material boundaries and, more importantly, graded transitions where one metal gradually blends into another.

This graded transition is the core technical achievement, as it prevents the structural failures that typically occur at the joints between two different materials.

Real-World Applications for Advanced Component Manufacturing

This is a proven prototype. The team has successfully printed multi-metal test objects, demonstrating immediate value for producing monolithic, complex components. The practical benefits for manufacturing include:

- Reduced Assembly: Parts that were multiple components welded or fastened together can be printed as a single unit.

- Weight Reduction: Components can be reinforced with stiff metals only where critical, using lighter alloys elsewhere to optimize mass.

- Integrated Functionality: A single part can merge properties like thermal conductivity (copper) and structural strength (steel).

Potential for Footwear Manufacturing and Tooling

It is essential to be clear: this is a lab-scale prototype. Widescale adoption in footwear production is not imminent. However, the technology aligns with specific, high-value applications:

- High-Performance Cleats and Spikes: The most direct application is in low-volume, high-end components. A 3D printed cleat could be fabricated with a hard-wearing tip material graded into a lighter, tougher alloy for the shaft, improving durability and reducing weight in a single, seamless part.

- Advanced Manufacturing Tooling: A more immediate use is indirect. This process could create sophisticated injection molds for plastic or foam midsoles. A mold could be printed with integrated copper cooling channels for drastically faster cycle times, increasing production efficiency for shoe manufacturers.

- Custom Orthotic Components: For medical and bespoke footwear, this technology could eventually enable the fabrication of orthotic supports that are rigid in one area and flexible in another, all from durable metal alloys without weak joints.

Developer Insights and Current Status

The students behind the project are focused on the technical milestone. Carlo D’Ambrosio stated the achievement allows the material composition to be “precisely tailored to the application’s requirements.” Luca Di Stasio highlighted the efficiency of the “extremely fast material switching” compared to previous systems.

The technology remains a university research project. Its future depends on further development to improve resolution and reliability, and on commercial interest to scale it for specific industrial applications.

Conclusion: A Incremental Step in Manufacturing Capability

The significance of this ETH Zurich 3D printing project is not an immediate revolution in footwear but a demonstrable advance in multi-material additive manufacturing. It provides a viable method for creating graded metal components that solve a key material integration problem. It is a promising tool for the future of manufacturing more functional, integrated, and durable products.